Control method for constant speed of hydraulic motor of multifunctional spraying vehicle and multifunctional spraying vehicle

A technology of hydraulic motor and control method, applied in the control algorithm type, spraying vehicle, pump control and other directions, can solve the problems of difficult to quickly and accurately adjust the hydraulic pump displacement, difficult to set closed-loop PID parameters, etc., to achieve constant speed and improve accuracy. , The effect of spraying water evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Exemplary embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings. Although exemplary embodiments of the present disclosure are shown in the drawings, it should be understood that the present disclosure may be embodied in various forms and should not be limited by the embodiments set forth herein. Rather, these embodiments are provided for more thorough understanding of the present disclosure and to fully convey the scope of the present disclosure to those skilled in the art.

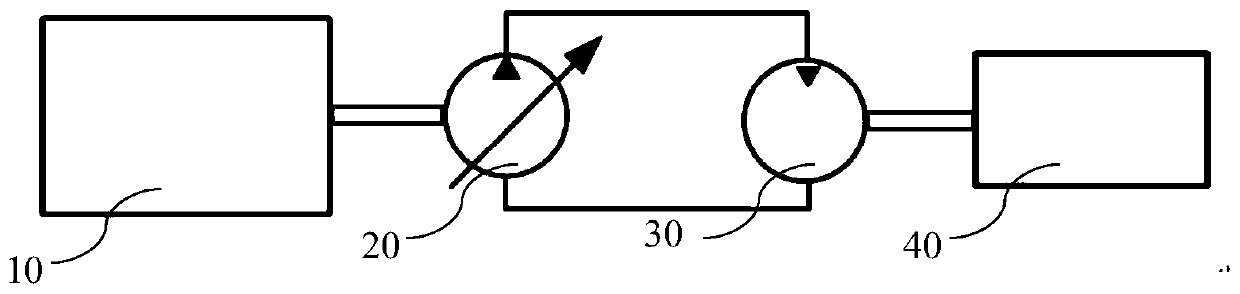

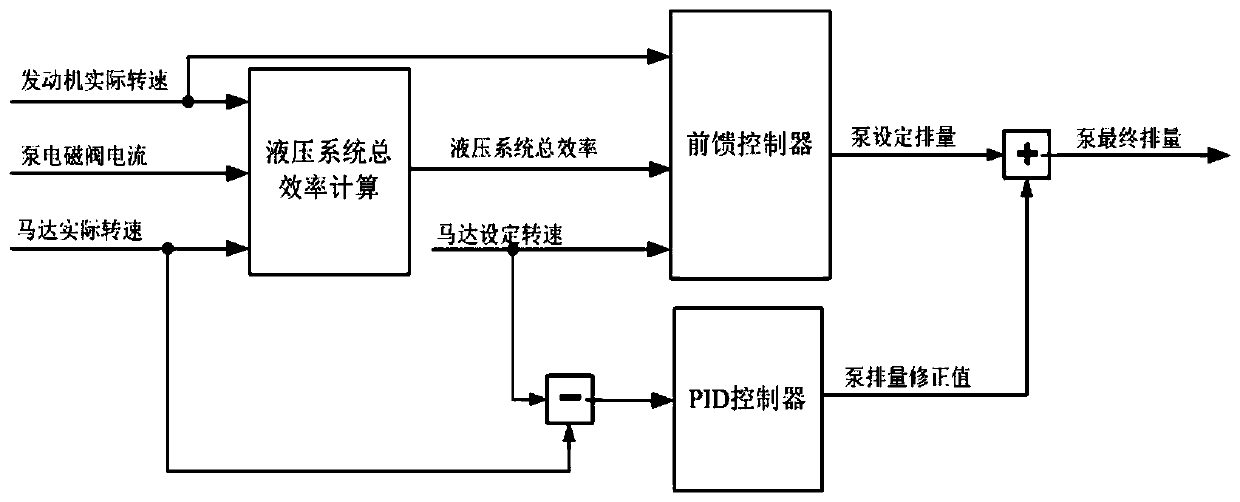

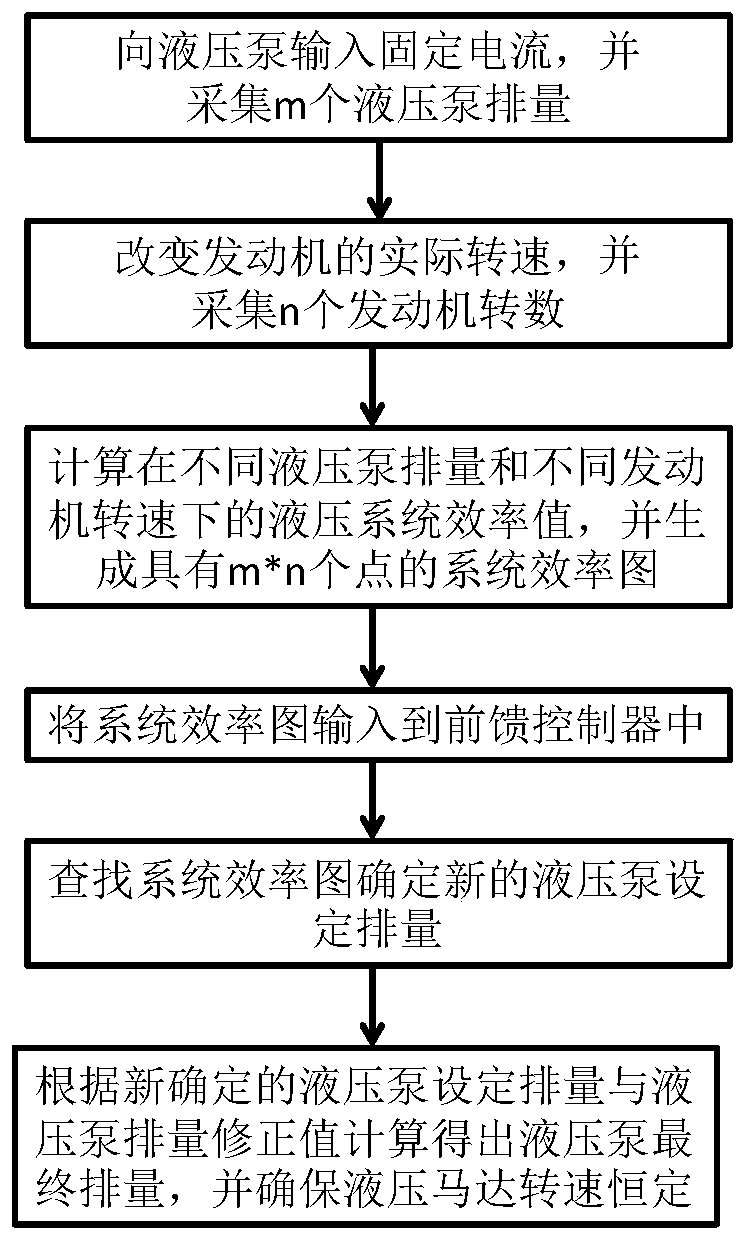

[0036] figure 1 It is a structural schematic diagram of the spraying system in the embodiment of the present invention. As shown, it includes an engine 10 , a hydraulic pump 20 , a hydraulic motor 30 and a spraying device 40 . Wherein, the hydraulic pump 20 is a variable displacement pump, and the hydraulic motor 30 is a quantitative motor. The spraying device 40 is driven by a hydraulic circuit composed of a hydraulic pump 20 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com