Tension roll control device for plate and strip processing line and tension control method

A technology of tension control and tension roller, which is applied in the direction of thin material handling, transportation and packaging, winding strips, etc., and can solve problems such as poor stability, low control precision, and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

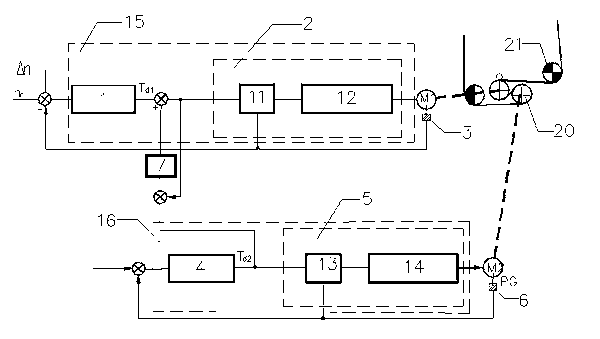

[0066] Such as figure 1 As shown, a tension roller tension control device on a strip processing line includes a tension roller group 20, a deviation correction device 21, an auxiliary roller frequency converter 15 and a main roller frequency converter 16; an auxiliary roller speed encoder 3, a main roller speed Encoder 6 and load distributor 7; tension roller group 20 includes auxiliary roller and main roller; auxiliary roller is connected with auxiliary roller motor, main roller is connected with main roller motor, auxiliary roller and main roller are controlled by auxiliary roller motor and main roller respectively Driven by a motor, the auxiliary roller speed encoder 3 detects the rotational speed signal of the auxiliary roller motor; the auxiliary roller frequency converter 15 is connected with the auxiliary roller motor and the auxiliary roller speed encoder 3; the main roller speed encoder 6 detects the main roller motor speed signal; The frequency converter 16 is connec...

Embodiment 2

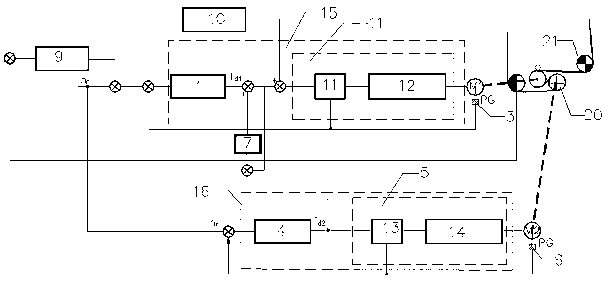

[0072] Such as figure 2 As shown, a tension roller tension control device on a strip processing line includes a tension roller group 20, a deviation correction device 21, an auxiliary roller frequency converter 15 and a main roller frequency converter 16; the tension roller group 20 includes an auxiliary roller and a main roller The auxiliary roller and the main roller are respectively driven by the auxiliary roller motor and the main roller motor; it also includes the auxiliary roller speed encoder 3, the main roller speed encoder 6 and the load distributor 7, and the auxiliary roller speed encoder 3 detects the auxiliary roller motor speed signal; the auxiliary roll frequency converter 15 is connected with the auxiliary roll motor and the auxiliary roll speed encoder 3; the main roll speed encoder 6 detects the speed signal of the main roll motor; the main roll frequency converter 16 is connected with the main roll motor and the main roll speed encoder 6 ; Both ends of the ...

Embodiment 3

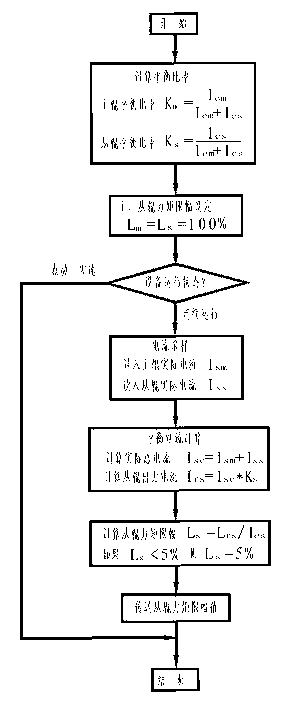

[0079] A method for controlling the tension of tension rollers on a strip processing line, comprising the following steps:

[0080] A) Tension roller master-slave load distribution: select two frequency conversion motors in the tension roller control system to control the main roller and auxiliary roller, one frequency conversion motor is the main drive to control the main roller, defined as the main roller motor, the main roller motor Using speed and torque double closed-loop control, through the vector frequency converter, the entire tension roll control system has a speed reference point, the frequency converter of the main roll motor is set to speed control mode; the other motor is a slave drive to control the auxiliary roll , is defined as the auxiliary roller motor, the frequency converter of the auxiliary roller motor is set to the torque control mode, and the additional speed setting value Δn is input through the speed control unit, when the speed control unit is satura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com