Turn seat supporting plate and preparation method thereof

A support plate and aluminum alloy technology, applied in the mechanical field, can solve problems such as difficult to bear stress, poor strength and toughness, and small stress, and achieve the effects of improving strength and corrosion resistance, increasing strength, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

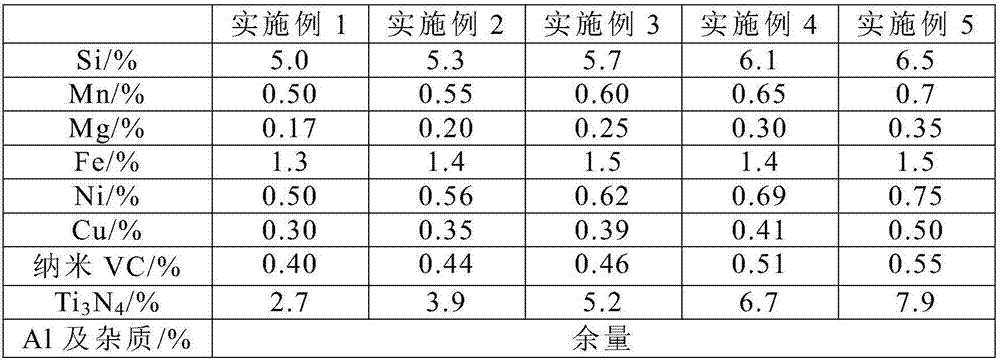

[0029] A swivel support plate in Examples 1-5 is made of aluminum alloy, and the aluminum alloy includes the following components in mass percentage: 5.0-6.5% Si, 0.5-0.7% Mn, 0.17-0.35% Mg, 1.3-1.5% %Fe, 0.5-0.75% Ni, 0.3-0.5% Cu, 0.4-0.55% nano VC, 2.8-7.9% Ti 3 N 4, the balance is Al and unavoidable impurities.

[0030] The total mass percentage of Cu and nano-VC is 0.8-0.95%.

[0031] Ti 3 N 4 Both nano-VC and nano-VC are added in the form of nano-powder, the particle size of nano-VC is 20-40nm, more preferably 20-30nm, Ti 3 N 4 The particle diameter is 40-75nm, more preferably 49-55nm.

[0032] The formulations of the aluminum alloys of Examples 1-5 are shown in Table 1 and Table 2.

[0033] Table 1: Components and mass percentages of the aluminum alloys of Examples 1 to 5

[0034]

[0035] Table 2: VC and Ti in Examples 1 to 5 3 N 4 particle size

[0036]

Embodiment 6

[0038] The preparation method of the swivel support plate in this embodiment includes the following steps,

[0039] (1), carry out batching according to the composition of raw materials in embodiment 3, with Ti 3 N 4 Ultrasonic dispersion of nano-VC raw material powder in the dispersion liquid, then freeze-drying, air-jet milling after freeze-drying to make powder; dispersion liquid includes the following components in mass percentage: 10% silane coupling agent acid, 15% polyethylene Glycol, 2% tartaric acid, the balance is ethanol;

[0040] (2), will remove Ti 3 N 4 Heating and smelting with other metal raw materials other than nano-VC into alloy melt, adding pretreated Ti 3 N 4 and nano-VC raw material powder, stir evenly;

[0041] (3) Pouring the stirred alloy melt into a green body, and then heat-treating the green body to obtain the finished turntable support plate; Compress the gas to a pressure of 60MPa, keep it warm for 4 hours, then increase the temperature to ...

Embodiment 7

[0043] The preparation method of the swivel support plate in this embodiment includes the following steps,

[0044] (1), carry out batching according to the composition of raw materials in embodiment 3, with Ti 3 N 4 and nano-VC raw material powder ultrasonically dispersed in the dispersion liquid, then freeze-dried, air-jet milled into powder after freeze-drying; the dispersion liquid includes the following components in mass percentage: 11% silane coupling agent acid, 16% polyethylene Glycol, 3% tartaric acid, the balance is ethanol;

[0045] (2), will remove Ti 3 N 4 Heating and smelting with other metal raw materials other than nano-VC into alloy melt, adding pretreated Ti 3 N 4 and nano-VC raw material powder, stir evenly;

[0046] (3) Pouring the stirred alloy melt into a green body, and heat-treating the green body to obtain the finished turntable support plate; Compress the gas to a pressure of 50 MPa, keep it warm for 3.5 hours, then increase the temperature to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com