Low-density environment-friendly drilling fluid capable of being repeatedly used for many times

A repeated, low-density technology, applied in the field of drilling fluid, can solve the problems of high production time and treatment agent costs, difficulty in controlling the solid phase content of drilling fluid, and restriction of drilling production speed, etc., to improve sand carrying capacity, Strong anti-pollution ability and the effect of reducing equipment power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

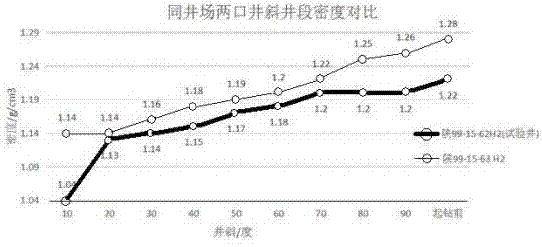

[0036] A kind of low-density environment-friendly drilling fluid that can be reused many times is divided into upper well section and lower well section according to well vertical depth. It is characterized in that: it is used for upper well section and for lower well section according to Mass ratio composition of components:

[0037] upper well section

[0038] Polymer shale inhibitor, 0.3-0.6%, function: polymer shale inhibitor, while enhancing the inhibition of drilling fluid, it increases the viscosity, which can slightly improve the sand-carrying ability of drilling fluid;

[0039] Flocculant, 0.2-0.5%, function: to coat and flocculate drill cuttings, and facilitate solid phase precipitation and removal of small volume drill cuttings;

[0040] Small molecule shale inhibitor, 2-8%, function: salt inhibitor, improve the inhibition and chemical anti-collapse ability of drilling fluid, form a film on the well wall and reduce the activity of drilling fluid;

[0041] Filtrate...

Embodiment 2

[0061] A kind of low-density environment-friendly drilling fluid that can be reused many times is carried out according to the following steps:

[0062] Step 1. After spud, start to enter the upper well section, formulate according to the mass ratio of the upper well section, first add the formulated amount of water into the wellbore, and then mix the mass ratio of 0.3 into the wellbore through the hydraulic slurry mixing funnel in the following order % macromolecule shale inhibitor, 0.2% flocculant by mass ratio, and 2% small molecule shale inhibitor by mass ratio, and circular drilling;

[0063] Step 2, after entering the middle of the Yanchang Formation in the upper well section, add fluid loss reducer with a mass ratio of 0.2% into the wellbore through the hydraulic slurry mixing funnel in the following order, and continue drilling;

[0064] Step 3. After entering the lower well section, start formulating according to the mass ratio of the lower well section. The specific ...

Embodiment 3

[0101] A kind of low-density environment-friendly drilling fluid that can be reused many times is carried out according to the following steps:

[0102] Step 1, after spud, start to enter the upper well section, formulate according to the formula mass ratio of the upper well section, first add the water of the formula amount into the wellbore, and then mix the mass ratio into the wellbore through the hydraulic slurry mixing funnel in the following order: 0.5% polymer shale inhibitor, 0.35% flocculant by mass ratio, 5% small molecule shale inhibitor by mass ratio, and circular drilling;

[0103] Step 2, after entering the middle of the Yanchang Formation in the upper well section, add fluid loss reducer with a mass ratio of 0.4% into the wellbore through the hydraulic slurry mixing funnel in the following order, and continue drilling;

[0104] Step 3. After entering the lower well section, start formulating according to the mass ratio of the lower well section. After entering t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com