Inner wall-grinding and heat-chamfering device and method for overlength large diameter aluminum alloy tube

A technology of aluminum alloy tubes and large diameters, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of poor grinding quality, low manual grinding efficiency of large-diameter aluminum alloy tube flashing, harsh environment, etc., and achieve automatic grinding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

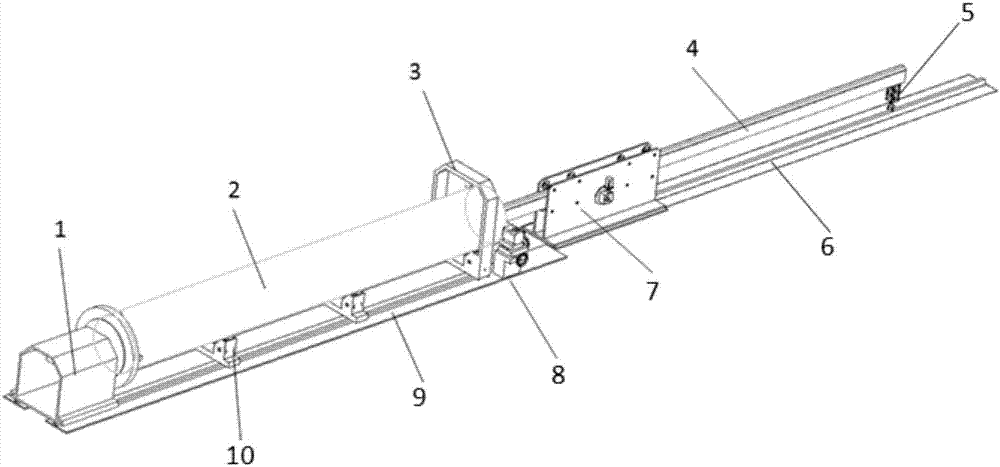

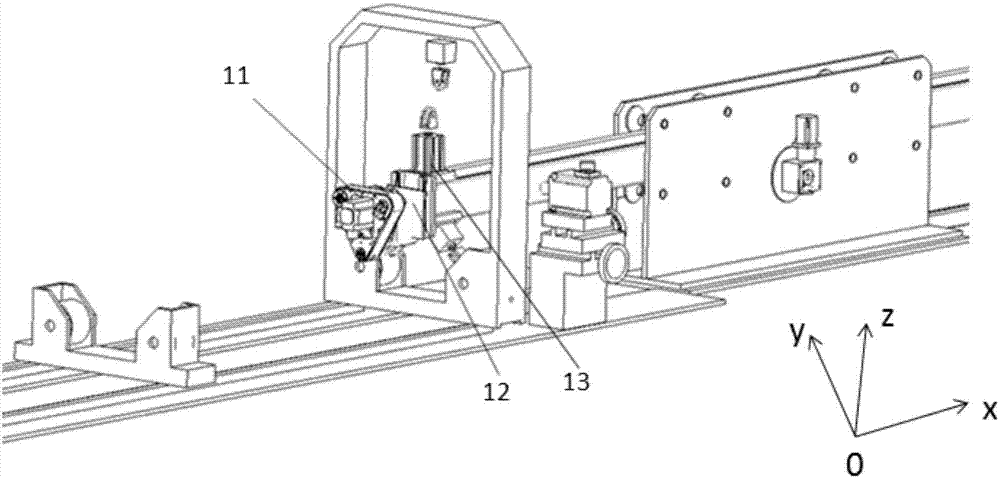

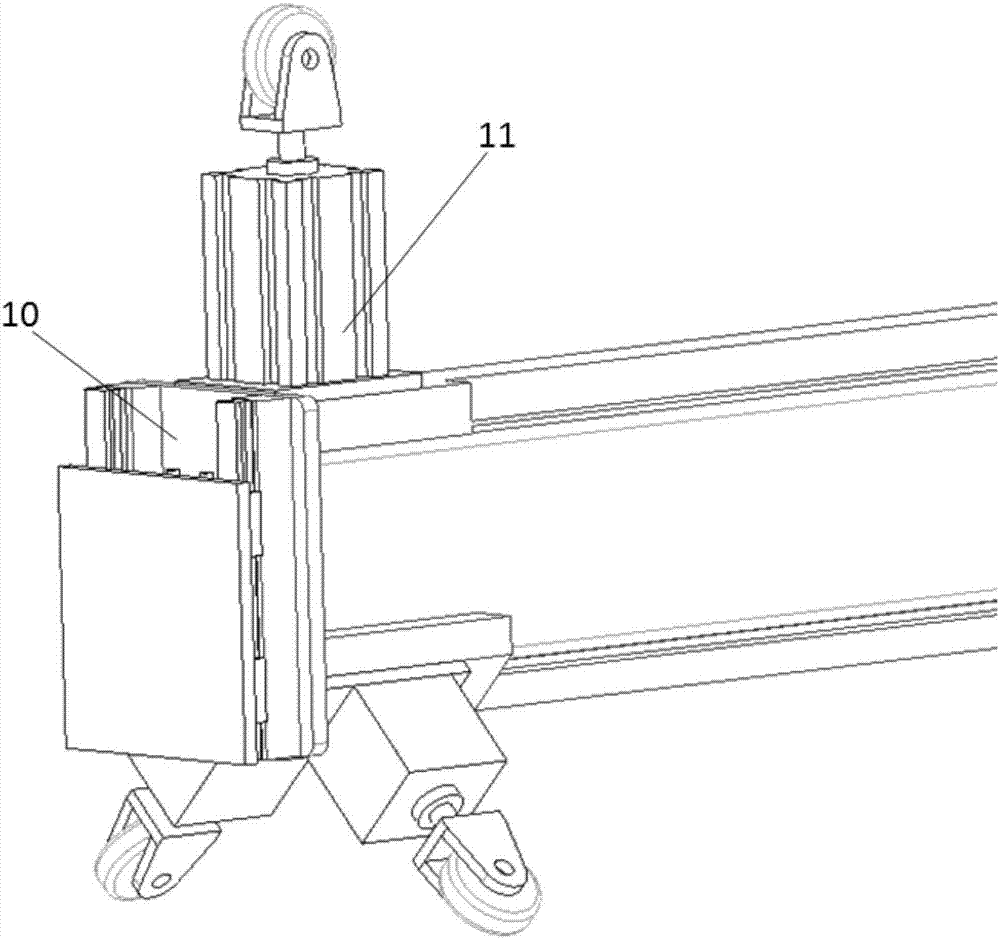

[0017] An ultra-long, large-diameter aluminum alloy tube inner wall grinding and flat-end chamfering device according to an embodiment of the present invention, a rotating seat 1, an aluminum alloy tube 2, a main bracket 3, a guide rod 4, a guide rod support wheel 5, and a base A6 , guiding power unit 7, flat head back corrugating device 8, base B9, auxiliary bracket 10, grinding head 11, compliant mechanism 12, grinding head support 13 etc.; The base is connected with the ground through expansion screws; the rotating The seat 1 and the main bracket 3 drive the aluminum alloy tube 2 to rotate; the grinding head 11 is installed on the end of the guide rod 4 for grinding the inner weld seam of the aluminum alloy tube 2; the guide power device 7 and the guide rod 4 drive the grinding The head 11 goes deep into the interior of the aluminum alloy pipe 2 to complete the internal welding seam grinding of the aluminum alloy pipe 2 . This device can effectively solve the disadvantages ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com