Tungsten rod welding device based on screw connecting technology

A technology of welding device and connection technology, which is applied in the direction of auxiliary devices, welding equipment, welding equipment, etc., and can solve the problems of tungsten rod breakage, risk, and tungsten rod not being straight enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

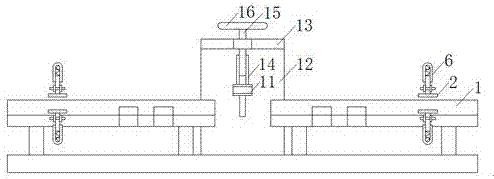

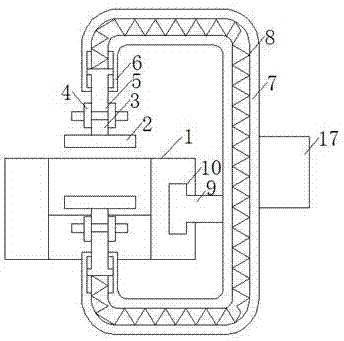

[0017] Such as Figure 1-2 As shown, a tungsten rod welding device based on screw connection technology includes a guide rail 1, the guide rail 1 is set as two left and right, and electrode holders and heaters are installed on the two guide rails 1, and the two electrode holders are located on two heating surfaces. The inner side of the device, the heater can be equipped with a torch head, which can be heated by gas combustion. These are all included in the reference materials, which are not the focus of this device, so they will not be described in detail. The guide rail 1 is fixed on the lower bottom plate through the support rod. , and the middle part of the inner cavity of the guide rail 1 is provided with a downwardly penetrating slot, and two upper and lower pressure plates 2 are arranged in the slot, and the outer ends of the two pressure plates 2 are provided with a vertically outward lower threaded rod 3, and the lower threaded rod The outer end of 3 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com