Magnetic macromolecular adsorption material, preparation method and application

An adsorption material and polymer technology, applied in chemical instruments and methods, magnetic field/electric field water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve problems such as being unable to adapt to the broad spectrum adsorption of organic substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

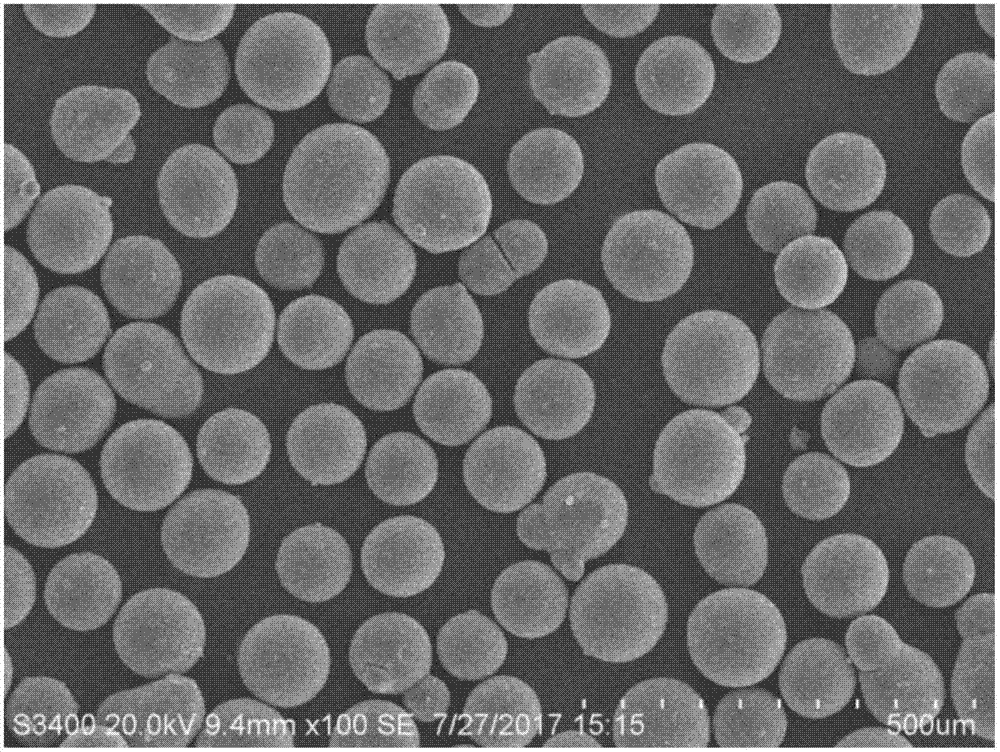

Image

Examples

Embodiment 1

[0039] In this embodiment, the steps for preparing the magnetic polymer adsorption material are as follows:

[0040] (1), preparation of magnetic Fe 3 o 4 @oleic acid nanoparticles: Add 1g of ferrous chloride and 2g of ferric chloride, 100mL of water into a 250mL flask, stir and mix evenly, protect with nitrogen, then add 4mol / L sodium hydroxide solution at 60°C 20mL, oleic acid 0.75g, at this moment, the quality of described oleic acid is magnetic Fe 3 o 4 0.5 times that of nanoparticles. After reacting for 10 hours, adjust the pH value of the solution to 3, wash the product with water and ethanol for 5 times, and obtain the magnetic Fe after drying. 3 o 4 @oleic acid nanoparticles.

[0041] (2), preparation of oil phase solution: 2g magnetic Fe 3 o 4 @Oleic acid nanoparticles were dissolved in 30mL of toluene solution, respectively added 3g N-vinylpyrrolidone, 3g divinylbenzene, 0.05g AIBN, and mixed in an ice bath to obtain an oil phase solution. The mass of N-vinyl...

Embodiment 2

[0057] In this embodiment, the steps for preparing the magnetic polymer adsorption material are as follows:

[0058] (1), preparation of magnetic Fe 3 o 4 @oleic acid nanoparticles: Add 2.6g ferrous chloride and 6.4 ferric chloride, 200mL water into a 500mL flask, stir and mix evenly, protect with nitrogen, then add 2mol / L potassium hydroxide at 100°C Solution 40mL, oleic acid 4g, the quality of described oleic acid is magnetic Fe 3 o 4 2 times that of nanoparticles; after 6 hours of reaction, the pH value of the solution was adjusted to 3. The product was washed 5 times with water and methanol and dried to obtain the magnetic Fe 3 o 4 @oleic acid nanoparticles.

[0059] (2), preparation of oil phase solution: 1g magnetic Fe 3 o 4 @Oleic acid nanoparticles were dissolved in 10mL of cyclohexanol solution, 2g of N-vinylpyrrolidone, 1.5g of divinylbenzene, and 0.07g of AIBN were added respectively, and mixed evenly in an ice bath to obtain an oil phase solution. The mass...

Embodiment 3

[0063] In this embodiment, the steps for preparing the magnetic polymer adsorption material are as follows:

[0064] (1), preparation of magnetic Fe 3 o 4 @oleic acid nanoparticles: Add 1g of ferrous chloride and 7g of ferric chloride, 100mL of water into a 250mL flask, stir and mix evenly, protect with nitrogen, then add 20mL of saturated ammonia solution and 3g of oleic acid at a temperature of 70°C , the quality of the oleic acid is magnetic Fe 3 o 4 1.7 times that of nanoparticles; the pH value of the solution was adjusted to 3 after reacting for 0.5 hours. The product was washed with water and methanol for 5 times and dried to obtain the magnetic Fe 3 o 4 @oleic acid nanoparticles.

[0065] (2), preparation of oil phase solution: 2g magnetic Fe 3 o 4@Oleic acid nanoparticles were dissolved in 30mL of DMF solution, 3g of N-vinylpyrrolidone, 2g of divinylbenzene, and 0.1g of BPO were added respectively, and mixed in an ice bath to obtain an oil phase solution. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Magnetization | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com