A gas-liquid surge mixing method

A gas-liquid and mixer technology, applied in mixing methods, gas/vapor and liquid mixing, chemical instruments and methods, etc., can solve problems such as affecting product quality, increasing production costs, and decreasing stirring efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] This embodiment provides a gas-liquid surge mixing method, which is carried out by using the float valve tower 1. The structure of the float valve tower 1 is as follows: Figure 7 As shown, the float valve tower 1 includes a multi-layer tray 2, the tray 2 is connected to the tower wall, and a round single light valve leg limit type float valve 3 is adopted. The height of the overflow weir 5 determines the height of the liquid level on the tray , Tower equipment scale, opening rate, overflow weir 5 height, valve weight are shown in Table 1.

[0082] Table 1 Structural parameters and operating parameters of the surge mixer

[0083]

[0084]

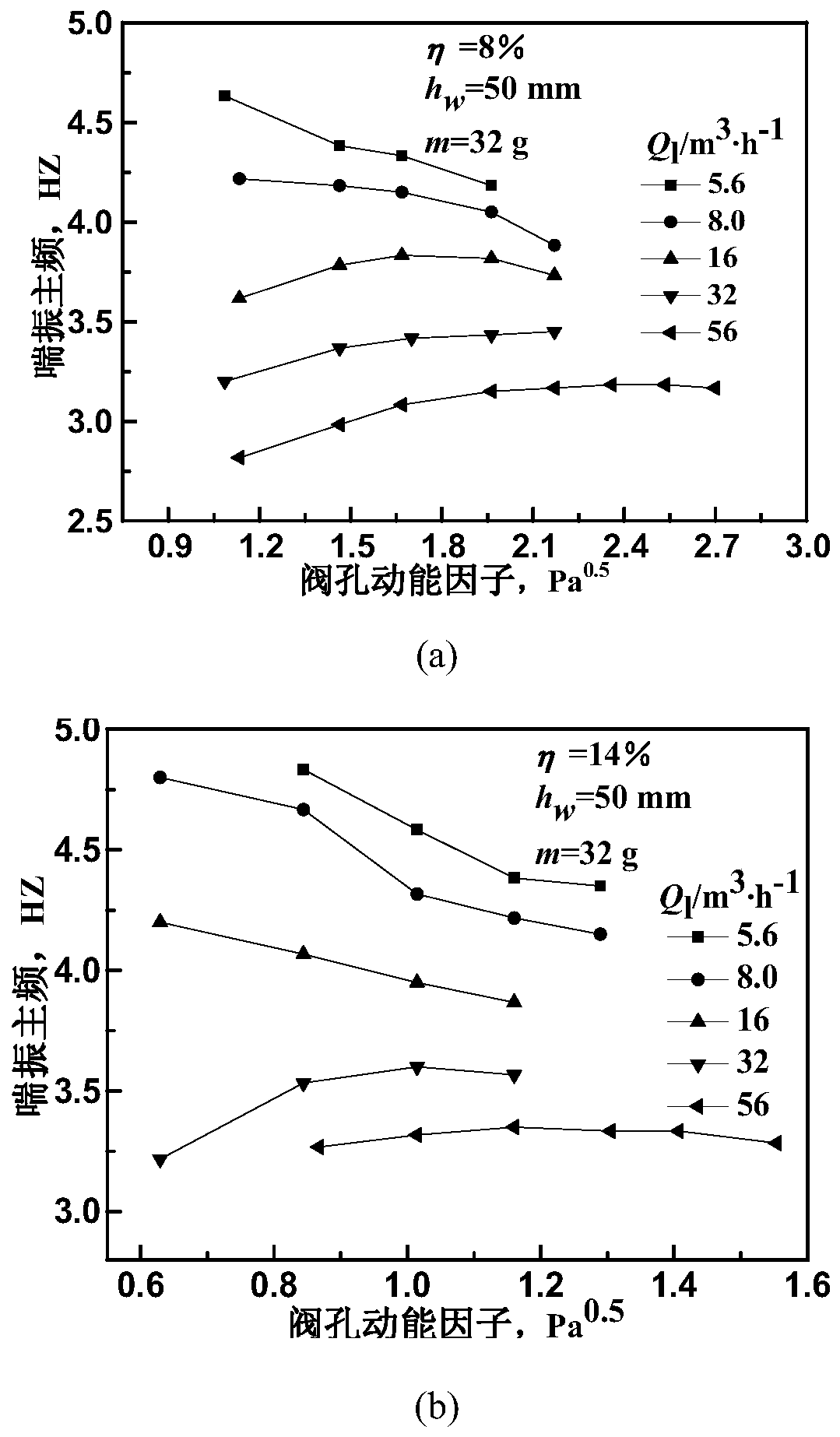

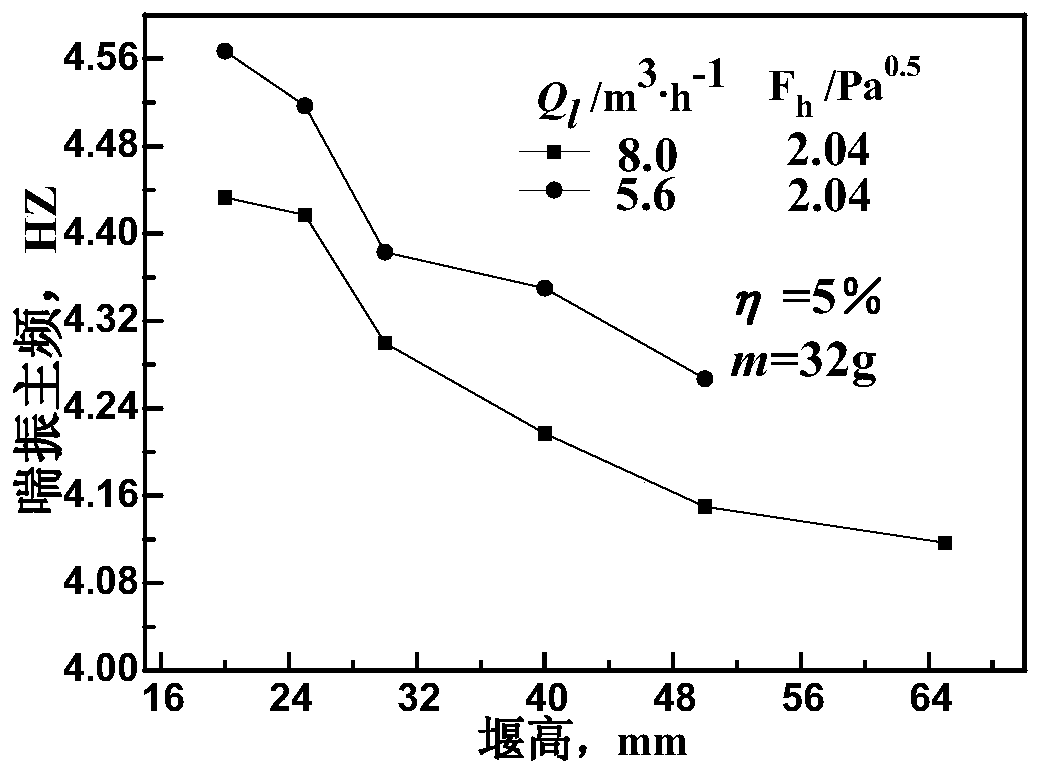

[0085] Where: F o Is the kinetic energy factor of the valve hole, u s Is the valve hole velocity, ρ V Is the gas phase density.

[0086] The main frequency of surge is measured experimentally. The pressure wave signal measured by the pressure sensor in the experiment, through Fourier transform and wavelet analysis, the part where the ampli...

Embodiment 2

[0092] This embodiment provides a gas-liquid surge mixing method, which is carried out by using the float valve tower 1. The structure of the float valve tower is as follows: Figure 7 As shown, the float valve tower 1 includes multi-layer trays 2. The trays 2 are connected to the tower wall, and a round single light valve leg limit type float valve 3 is adopted. The tower equipment scale, opening rate, weir height, and valve weight are as Table 2 shows.

[0093] Table 2 Structural parameters and operating parameters of the surge mixer

[0094]

[0095] The method includes the following steps:

[0096] The liquid phase is fed from the upper part of the valve tower 1, and flows in the horizontal direction on the valve tray 2 after feeding, and then the liquid is diverted from the downcomer 4 to the lower tray 2, and the gas phase enters from the lower part of the valve tower 1. The material rises from the bottom of the tray 2 through the openings of the tray in pulse bubbling, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tower diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com