High humidity sulfur oxide tail gas treatment method and device

A technology of sulfur oxides and high humidity, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems that the flue gas temperature cannot be effectively reduced and affects the desulfurization effect, so as to prevent ammonia escape and aerosol, and is widely used Applicability, the effect of reducing absolute humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

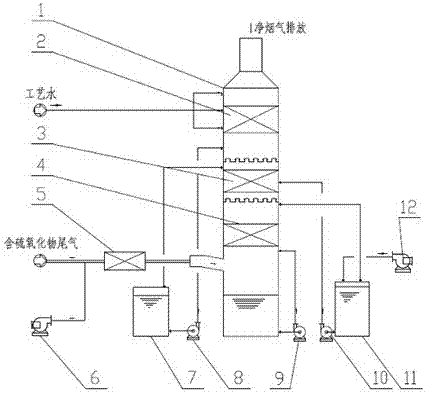

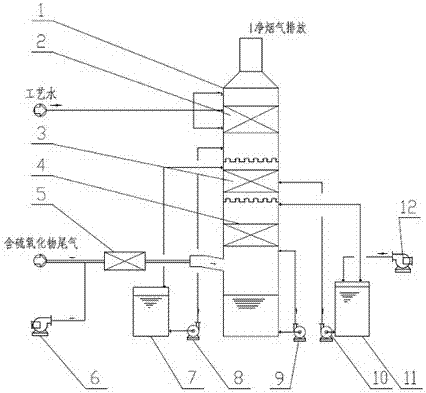

[0051] Total exhaust gas: 123000Nm 3 / h, flue gas temperature 145°C, absolute humidity 28%, flue gas sulfur oxide content 20000mg / Nm 3 , pressure 110kPa; desulfurizer is liquid ammonia, concentration 99.6%.

[0052] Process flow and equipment: The flue gas is blown into the normal temperature air by the blower, and the absolute humidity drops to 16%. It enters the cooling area of the absorption tower, and is sprayed with ammonium sulfate solution to cool down. The temperature of the flue gas drops to 57°C, and the flue gas passes through the absorption area, After washing the purification area, it is discharged from the chimney after passing through the clean flue.

[0053] The concentration of sulfur dioxide in the exhaust gas is 23mg / Nm 3 , the particle concentration is 3.23mg / Nm 3 .

Embodiment 2

[0055] Total exhaust gas: 264700Nm 3 / h, flue gas temperature 162°C, absolute humidity 31.2%, flue gas sulfur oxide content 5800mg / Nm3, pressure 2000Pa; desulfurizer is ammonia water, concentration 15%.

[0056] Technological process and equipment: The flue gas first enters the adsorption device equipped with calcium chloride, the absolute humidity drops to 10%, enters the cooling zone of the absorption tower, and is sprayed with ammonium sulfate solution to cool down, the flue gas temperature drops to 51°C, and the flue gas is sequentially After passing through the absorption area and water washing purification area, it is discharged from the chimney after passing through the clean flue.

[0057] The concentration of sulfur dioxide in the exhaust gas is 15mg / Nm 3 , the particle concentration is 2.62mg / Nm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com