An intelligent heat dissipation material, battery heat dissipation explosion-proof device and manufacturing method thereof

A technology of heat dissipation materials and explosion-proof devices, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of high energy consumption, battery collision and explosion, and low battery heat dissipation rate, so as to achieve high molecular activity and reduce the risk of explosion , Good cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Specifically, the preparation method of the above-mentioned intelligent heat dissipation material may include the following steps:

[0048] Step a: Composite silica gel with smart isopropylacrylamide polymer to obtain smart isopropylacrylamide polymer compound, usually powder; mix smart isopropylacrylamide polymer compound with aloe vera gel to obtain jelly ;

[0049] Combining graphene with sintered ceramic clay to obtain a graphene composite;

[0050] Step b: Colloid with graphene composite, TiO 2 and Al 2 o 3 Mix evenly to get intelligent heat dissipation material.

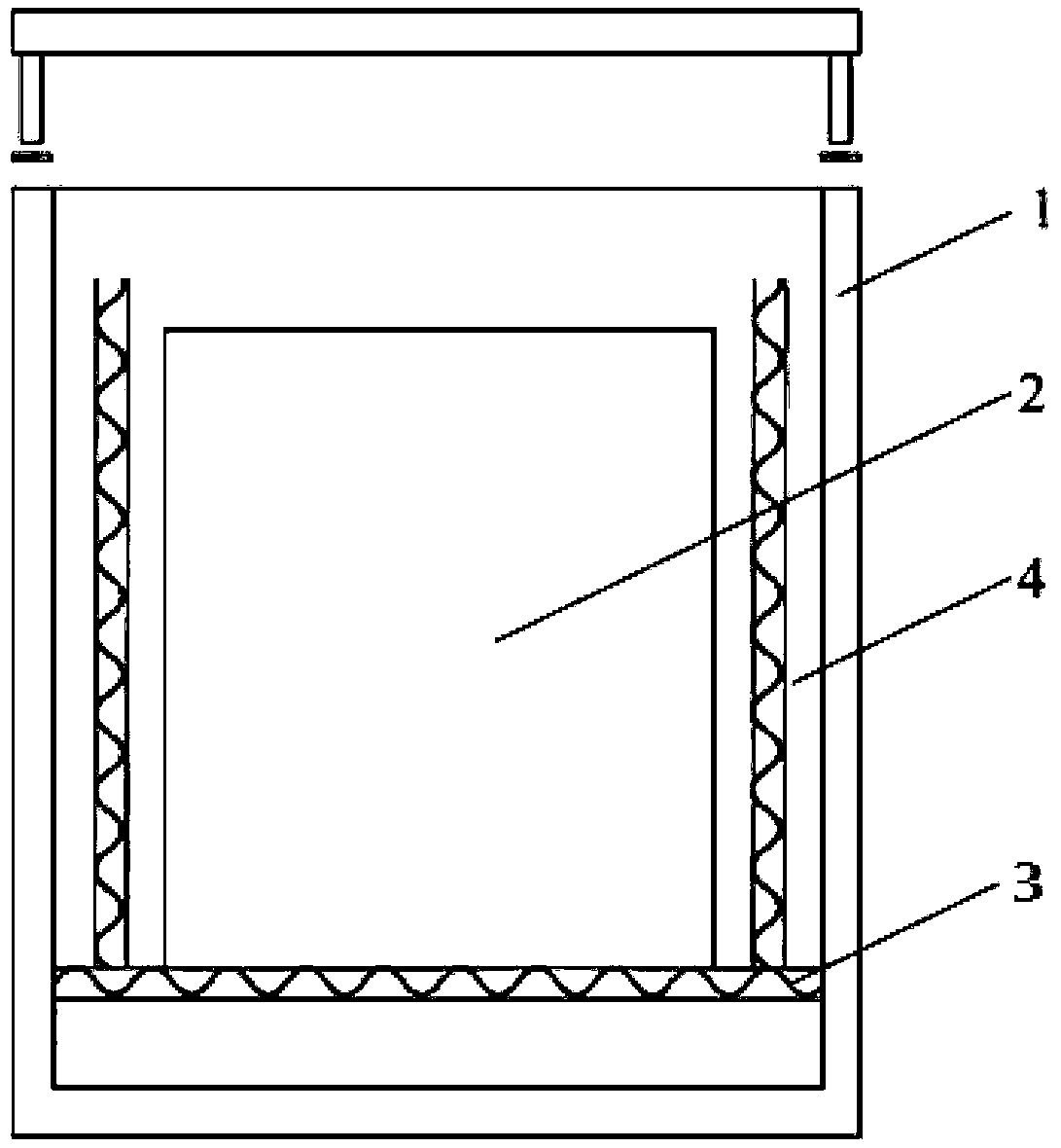

[0051] In the second aspect, the present invention provides a battery cooling and explosion-proof device, such as Figure 2 to Figure 5 As shown, the explosion-proof box 1 and the intelligent heat dissipation material filled inside the explosion-proof box 1 are included. When in use, the battery 2 is located in the explosion-proof box 1 and the intelligent heat dissipation material surrounds the bat...

Embodiment 1

[0079] This embodiment provides an intelligent heat dissipation material, the mass percentage of its components is 5% of intelligent isopropylacrylamide polymer, 6% of aloe gel, 24% of silica gel, 5% of graphene, and 33% of ceramic clay after sintering 、TiO 2 5%, Al 2 o 3 twenty two%.

[0080] The preparation method of the above intelligent heat dissipation material comprises the following steps:

[0081] 24 parts (parts by mass) of silica gel and 5 parts of intelligent isopropylacrylamide polymer are compounded to obtain intelligent isopropylacrylamide polymer compound; the intelligent isopropylacrylamide polymer compound is mixed with 6 parts of aloe vera gel Obtain jelly; 5 parts of graphene are compounded with ceramic clay after 33 parts of sintering to obtain graphene composite; jelly and graphene composite, 5 parts of TiO 2 and 22 Al 2 o 3 Mix evenly to get intelligent heat dissipation material.

Embodiment 2

[0083] This embodiment provides an intelligent heat dissipation material, the mass percent of its components is 24% of intelligent isopropylacrylamide polymer, 5% of aloe gel, 32% of silica gel, 12% of graphene, and 10% of sintered ceramic clay 、TiO 2 12%, Al 2 o 3 5%.

[0084] The preparation method of the above intelligent heat dissipation material comprises the following steps:

[0085] 32 parts (parts by mass) of silica gel and 24 parts of intelligent isopropylacrylamide polymer are compounded to obtain intelligent isopropylacrylamide polymer compound; the intelligent isopropylacrylamide polymer compound is mixed with 5 parts of aloe vera gel Obtain jelly; 5 parts of graphene are compounded with 10 parts of ceramic clay after sintering to obtain graphene composite; jelly and graphene composite, 12 parts of TiO 2 and 5 Al 2 o 3 Mix evenly to get intelligent heat dissipation material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com