Preparation method of high-voltage sodium ion supercapacitor

A supercapacitor and sodium ion technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problems of reducing the specific capacity and cycle life of sodium ion batteries, and structural collapse, and achieve environmental friendliness , Strong contact and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

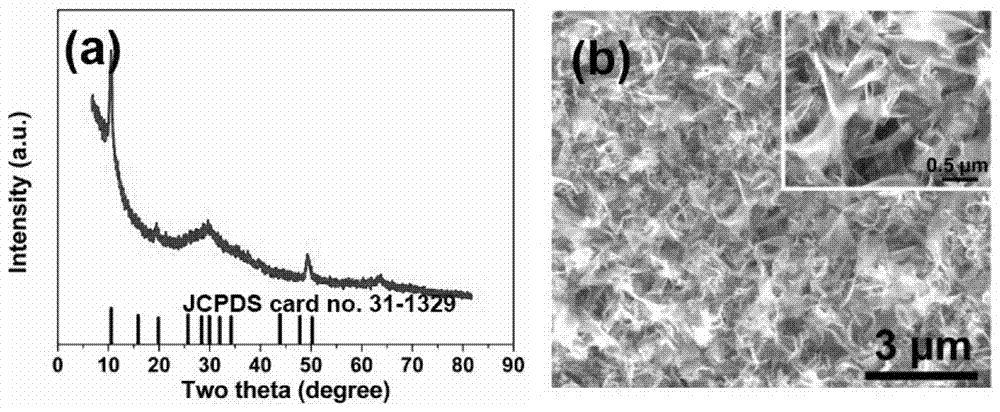

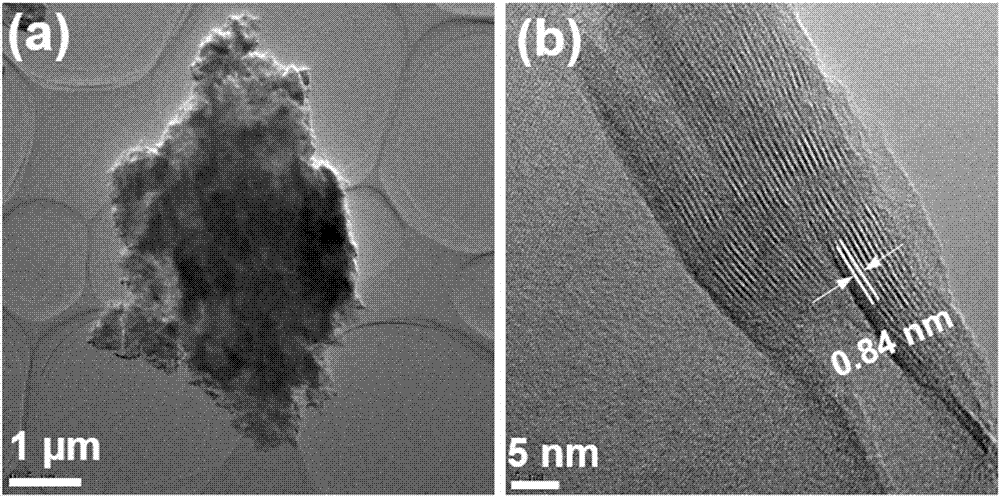

Embodiment 1

[0020] First place the Ti sheet in 1 M NaOH solution at an angle of 60 degrees and place it in an oven at 180 o C for 12 h. Then the film obtained after the hydrothermal reaction was placed in a tube furnace for 5 o Cmin -1 Speed up to 400 o After keeping at C for 1 h and cooling naturally to obtain Na 2 Ti 3 o 7 Nanosheet arrays. figure 1 For the prepared Na 2 Ti 3 o 7 XRD patterns and corresponding SEM images of the arrays. It can be seen from the XRD pattern that Na 2 Ti 3 o 7 The characteristic peak, its XRD pattern and Na 2 Ti 3 o 7 (JCPDS No.31-1329) card is consistent. Through the corresponding SEM image we can see that Na 2 Ti 3 o 7 The nanosheet arrays are orderly distributed on the titanium substrate with a size of 1-2 µm. figure 2 for the corresponding Na 2 Ti 3 o 7 TEM images of nanosheets, which can determine individual Na 2 Ti 3 o 7 Nanosheets have a distinct porous structure. pass figure 2 The high-resolution TEM test in b can see...

Embodiment 2

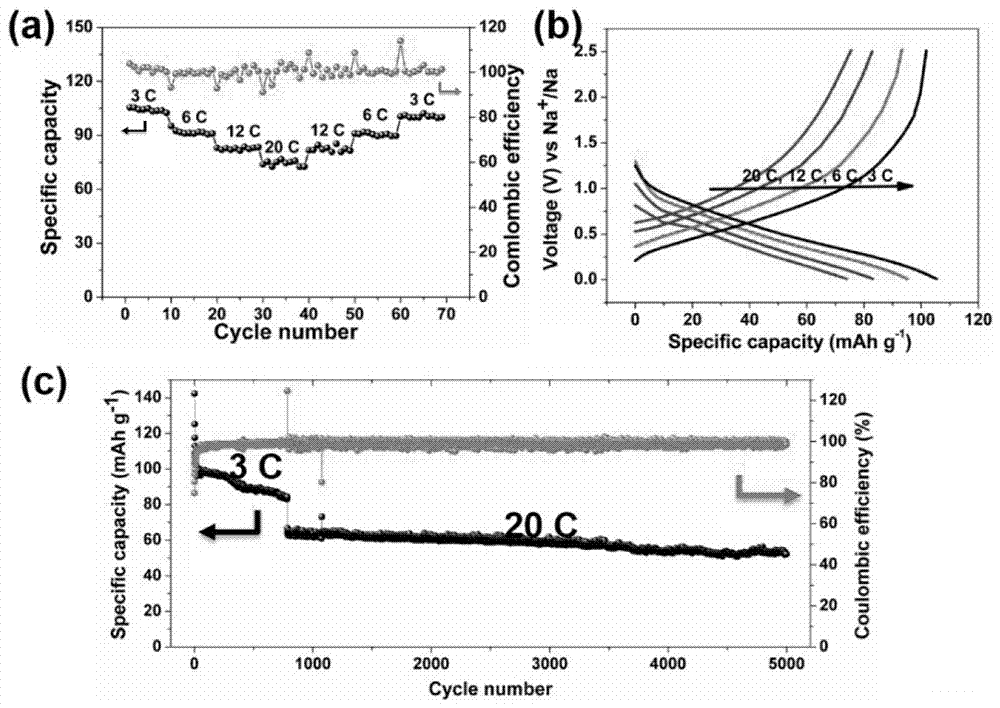

[0022] First place the Ti sheet in 1 M NaOH solution at an angle of 60 degrees and place it in an oven at 180 o C for 12 h. Then the film obtained after the hydrothermal reaction was placed in a tube furnace for 5 o Cmin -1 Speed up to 400 o After keeping at C for 1 h and cooling naturally to obtain Na 2 Ti 3 o 7 Nanosheet array, active material Na 2 Ti 3 o 7 Mass is 1 mg cm -1 . Directly use 5 g potassium citrate as carbon source, place it in a nitrogen atmosphere to o Cmin -1 Speed up to 800 o C and kept for 3 h, filtered and dried to obtain carbon nanosheet powder after washing with 0.3 M dilute hydrochloric acid. We use carbon nanosheets and Na 2 Ti 3 o 7 The nanosheet array is used as the positive electrode and negative electrode material of the sodium ion supercapacitor respectively, and the mass ratio of the active material of the positive and negative electrode materials is 4:1. The prepared hybrid supercapacitor is at 825 W kg -1 The energy densi...

Embodiment 3

[0024] First place the Ti sheet in 1 M NaOH solution at an angle of 60 degrees and place it in an oven at 180 o C for 12 h. Then the film obtained after the hydrothermal reaction was placed in a tube furnace for 5 o Cmin -1 Speed up to 400 o After keeping at C for 1 h and cooling naturally to obtain Na 2 Ti 3 o 7 Nanosheet arrays. Directly use 5 g potassium citrate as carbon source, place it in a nitrogen atmosphere to o Cmin -1 Speed up to 800 o C and kept for 3 h, filtered and dried to obtain carbon nanosheet powder after washing with 0.3 M dilute hydrochloric acid. We use carbon nanosheets and Na 2 Ti 3 o 7 The nanosheet array is used as the positive electrode and negative electrode material of the sodium ion supercapacitor respectively, and the mass ratio of the active material of the positive and negative electrode materials is 4.5:1. The prepared hybrid supercapacitor at 825 Wkg -1 The energy density under the power density is 72.6 Wh kg -1 . at 2 A g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com