Bevel gear ultrasonic automatic detection device and method

An automatic detection device and technology of detection device, which are applied in measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves, etc., can solve the problems of low detection efficiency, detection error, complicated operation, etc. , to achieve the effect of high detection efficiency, accurate vertical positioning and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

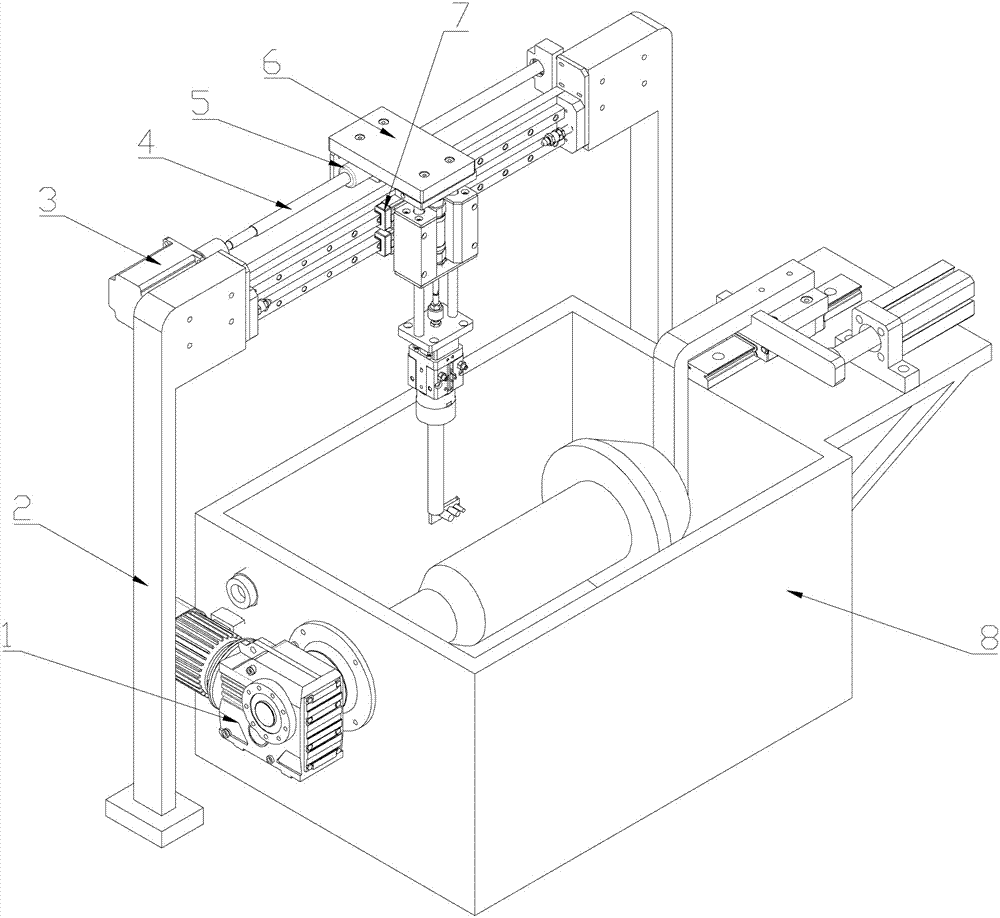

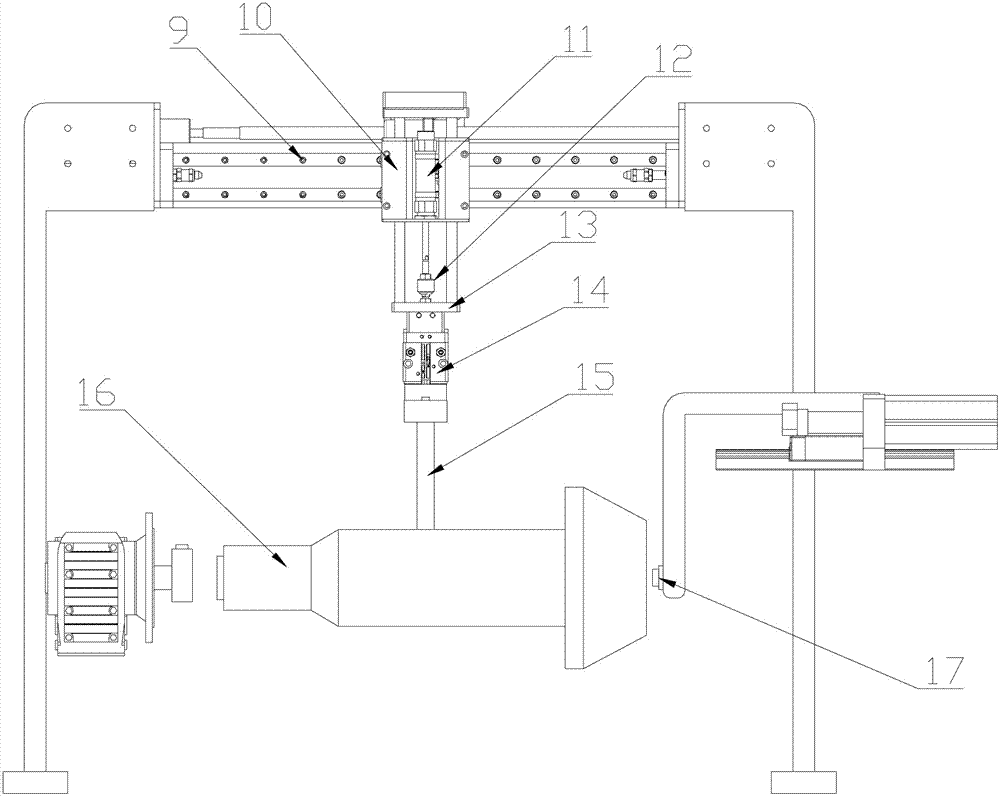

[0035] see Figure 1-4 , an ultrasonic automatic detection device for bevel gears, which includes a positioning and rotating device for bevel gear positioning, a sliding device is fixedly installed above the positioning and rotating device through a support frame 2, and a connecting plate 13 below the sliding device A testing device for ultrasonic testing is installed. The device can realize the ultrasonic automatic detection of bevel gears. The device uses layered array longitudinal wave straight probes to detect flaws from the surface of the workpiece, and uses probes with different frequencies to detect different depths of the workpiece. It can accurately and effectively detect internal defects of the workpiece, and the detection efficiency is higher. High and suitable for bevel gear testing of various specifications.

[0036] Further, the workpiece positioning and rotating device includes a water tank 8, a motor 1 is fixedly installed on the left outer wall of the water t...

Embodiment 2

[0043] The detection method of any described bevel gear ultrasonic automatic detection device, it comprises the following steps:

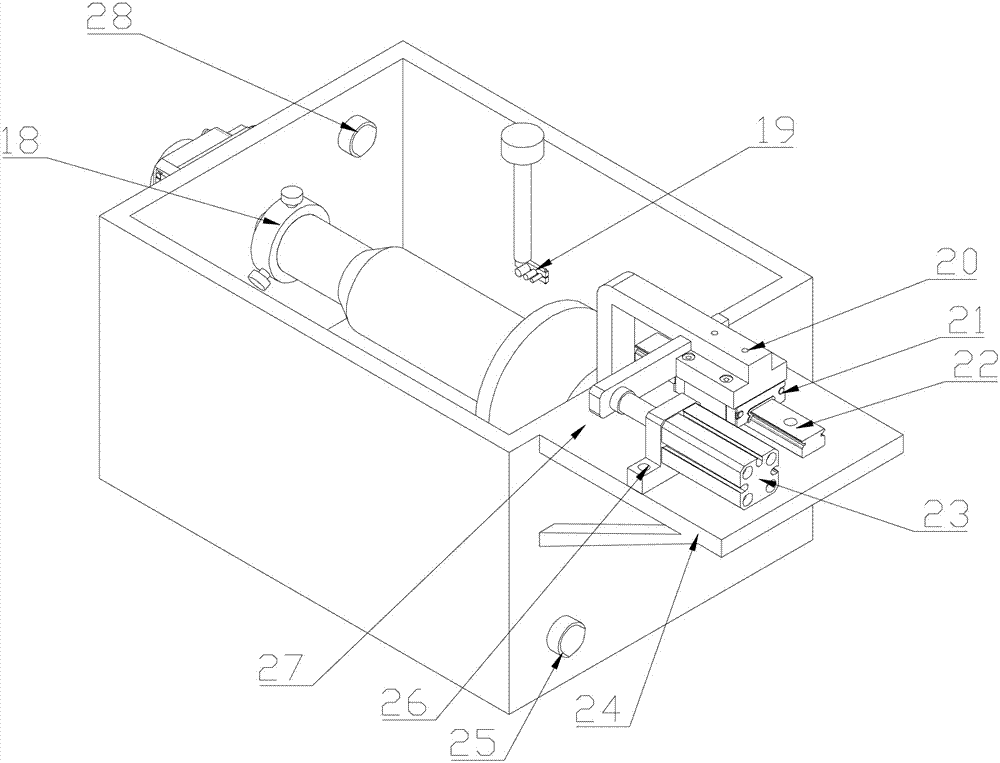

[0044] Step1: According to the size of the bevel gear 16 to be detected, select an array probe 19 of a suitable model, install it on the probe fixture at the end of the probe bracket 15, and connect the probe to the ultrasonic detector;

[0045] Step2: Install the shaft end of the bevel gear 16 to be tested on the three-jaw chuck 18, and tighten the three-jaw chuck 18 to clamp and position the shaft end;

[0046] Step3: push the cylinder 23 to drive the positioning device, drive the head bracket 20 to move, and tighten the head 17 to the end face of the bevel gear 16 to be tested, and complete the clamping and positioning of the bevel gear 16 to be tested;

[0047] Step4: After the bevel gear 16 to be detected is positioned, fill water into the water tank 8 through the water inlet 28, and when the water is full, drive the bevel gear to rotate throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com