Novel thermal insulating wall connecting unit

A technology for thermal insulation walls and connectors, applied in thermal insulation, building components, buildings, etc., can solve the problems of low shear strength, low construction efficiency, complex layout, etc., to increase the friction coefficient, save work time, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

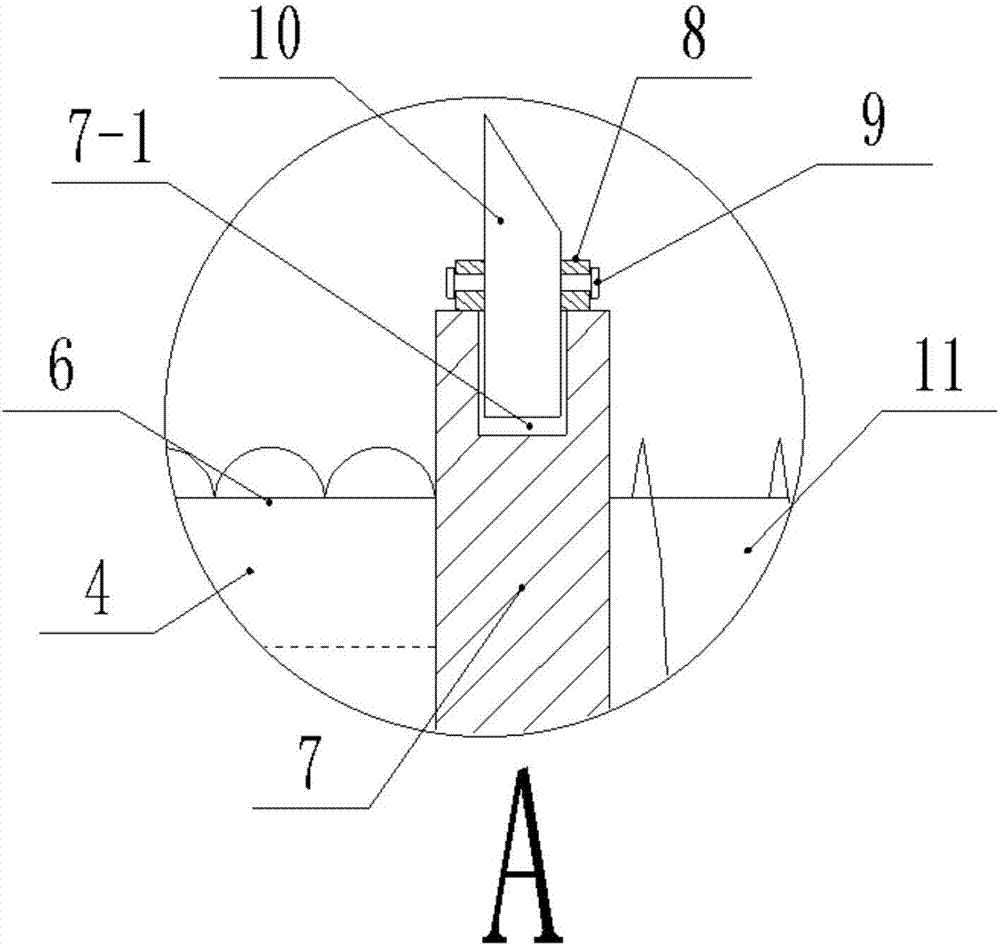

[0023] Referring to the accompanying drawings, the present invention will be further described in detail below in conjunction with specific embodiments, which are explanations rather than limitations of the present invention.

[0024] As shown in the drawings, a new type of thermal insulation wall connector includes a positioning block 1 and a connecting rod 3 arranged on one side of the positioning block 1; one end of the positioning block 1 is fixed with a first sleeve 2, and the first A sleeve 2 is fixed with an internal thread 2-1, one end of the connecting rod 3 close to the positioning block 1 is fixed with an external thread 3-1, and the other end of the connecting rod 3 is inserted into the plastic collar 4, and the internal thread 2-1 is matched with the external thread 3-1, the section of the plastic collar 4 is a circular section, the connecting rod 3 and the plastic collar 4 adopt an interference fit, and the plastic collar 4 is close to the outside of the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com