Synthetic method for corrosion-resistant water-based coating

A technology of water-based paint and synthesis method, applied in anti-corrosion paint, coating and other directions, can solve the problems of poor anti-settling performance, poor anti-corrosion performance, single protective performance, etc., and achieve low cost, strong corrosion resistance and anti-settling performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

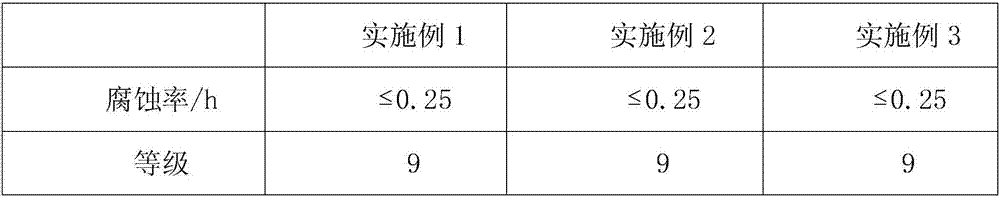

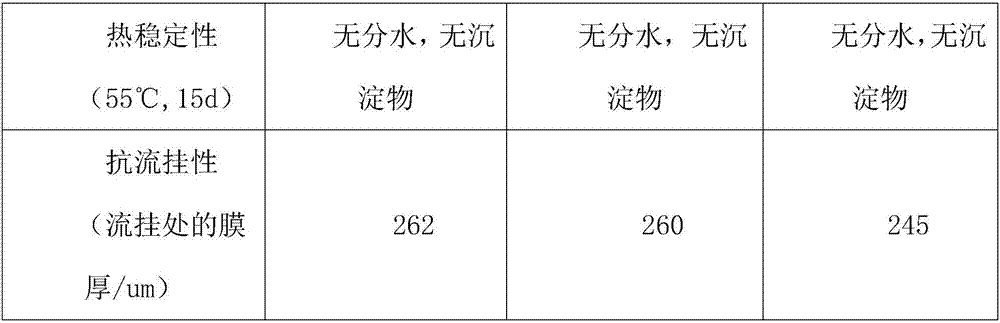

Embodiment 1

[0035] A kind of synthetic method of corrosion-resistant water-based paint:

[0036] (1) Heat and melt the acrylic resin, add polyvinyl alcohol, and stir for 25 minutes. After the polyvinyl alcohol is completely dissolved, add water into the stirring tank and heat to 95°C. The stirring speed is 480r / min, and stir for 1.5 hours;

[0037] (2) Add defoamer and anti-settling additive, stir for 1.5 hours, and cool down to 38°C;

[0038] (3) Add sodium dodecylsulfonate and dioctyl ester, and continue to stir for 1.7 hours;

[0039] (4) Stop stirring, add nano-silica in the reactor, and ultrasonically vibrate for 2 hours;

[0040] (5) Heat the reactor to 80°C for 3.4 hours, add diatomaceous earth, triethanolamine and silane coupling agent again, keep the temperature for 4 hours, close the reactor, add phosphate, and stir for 1 hour to obtain corrosion-resistant water coating.

[0041] The anti-corrosion water-based paint in the anti-corrosion water-based paint synthesis method com...

Embodiment 2

[0044] A kind of synthetic method of corrosion-resistant water-based paint:

[0045] (1) After heating and melting the acrylic resin, add polyvinyl alcohol and stir for 25 minutes. After the polyvinyl alcohol is completely dissolved, add water into the stirring tank and heat to 95°C. The stirring speed is 450r / min, and stir for 1.5 hours;

[0046] (2) Add defoamer and anti-settling additive, stir for 1.5 hours, and cool down to 35°C;

[0047] (3) Add sodium dodecylsulfonate and dioctyl ester, and continue to stir for 1.5 hours;

[0048] (4) Stop stirring, add nano-silica in the reactor, and ultrasonically vibrate for 2 hours;

[0049] (5) Heat the reactor to 85°C for 3.5 hours, add diatomaceous earth, triethanolamine and silane coupling agent again, keep the temperature for 4.2 hours, close the reactor, add phosphate, and stir for 1 hour to obtain corrosion-resistant water coating.

[0050] The corrosion-resistant water-based paint in the anti-corrosion water-based paint sy...

Embodiment 3

[0053] A kind of synthetic method of corrosion-resistant water-based paint:

[0054] (1) After heating and melting the acrylic resin, add polyvinyl alcohol and stir for 25 minutes. After the polyvinyl alcohol is completely dissolved, add water into the stirring tank and heat to 95°C. The stirring speed is 500r / min, and stir for 1.5 hours;

[0055] (2) Add defoamer and anti-settling additive, stir for 1.5 hours, and cool down to 45°C;

[0056] (3) Add sodium dodecylsulfonate and dioctyl ester, and continue to stir for 2 hours;

[0057] (4) Stop stirring, add nano-silica in the reactor, and ultrasonically vibrate for 2 hours;

[0058] (5) Heat the reactor to 90°C for 3 hours, then add diatomaceous earth, triethanolamine, and silane coupling agent again, keep the temperature for 4.5 hours, close the reactor, add phosphate, and stir for 1 hour to obtain corrosion-resistant water coating.

[0059] The anti-corrosion water-based paint in the anti-corrosion water-based paint synthes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com