Organic waste gas recovery processing device

A technology for recovery and treatment of organic waste gas, applied in gas treatment, dispersed particle filtration, membrane technology, etc., to achieve the effects of reducing operating costs, reducing the frequency of hot spots, and stabilizing chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

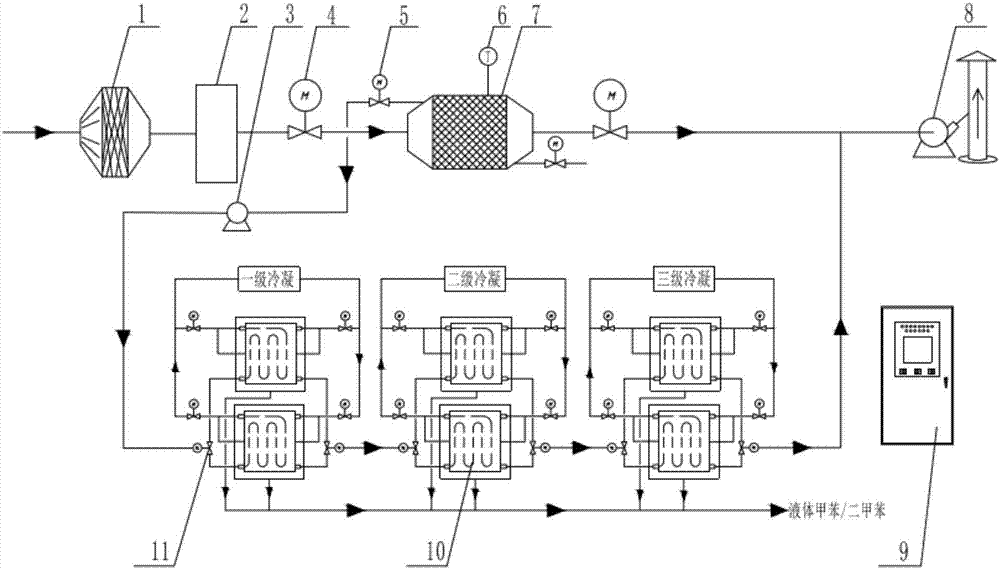

[0022] The organic waste gas recovery and treatment device and its process flow of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] According to the characteristics of the solvent used by the user, that is, the chemical property is stable and does not polymerize. The use of coal-based granular activated carbon is very suitable for the repeated adsorption and desorption of these solvent volatile gases. The desorption performance is very good, and the natural temperature resistance is as high as 450°C. It can not only effectively ensure the regeneration effect of the system, but also greatly reduce the frequency of hot spots. Optimum security for industrial applications. According to the adsorption characteristics of activated carbon, the operation process of micro positive pressure adsorption, negative pressure analysis (desorption) combined with cryogenic recovery is used to create favorable adsorption and desorption...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com