Clothes shell fabric sterilizing method

A technology for fabrics and clothing, applied in water supply devices, sanitary equipment for toilets, buildings, etc., can solve the problems of ineffective disinfection and poor disinfection effect, achieve good disinfection effect, improve sterilization effect, and remove dead corners of fabrics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Clothing fabric sterilization method, comprises the following steps:

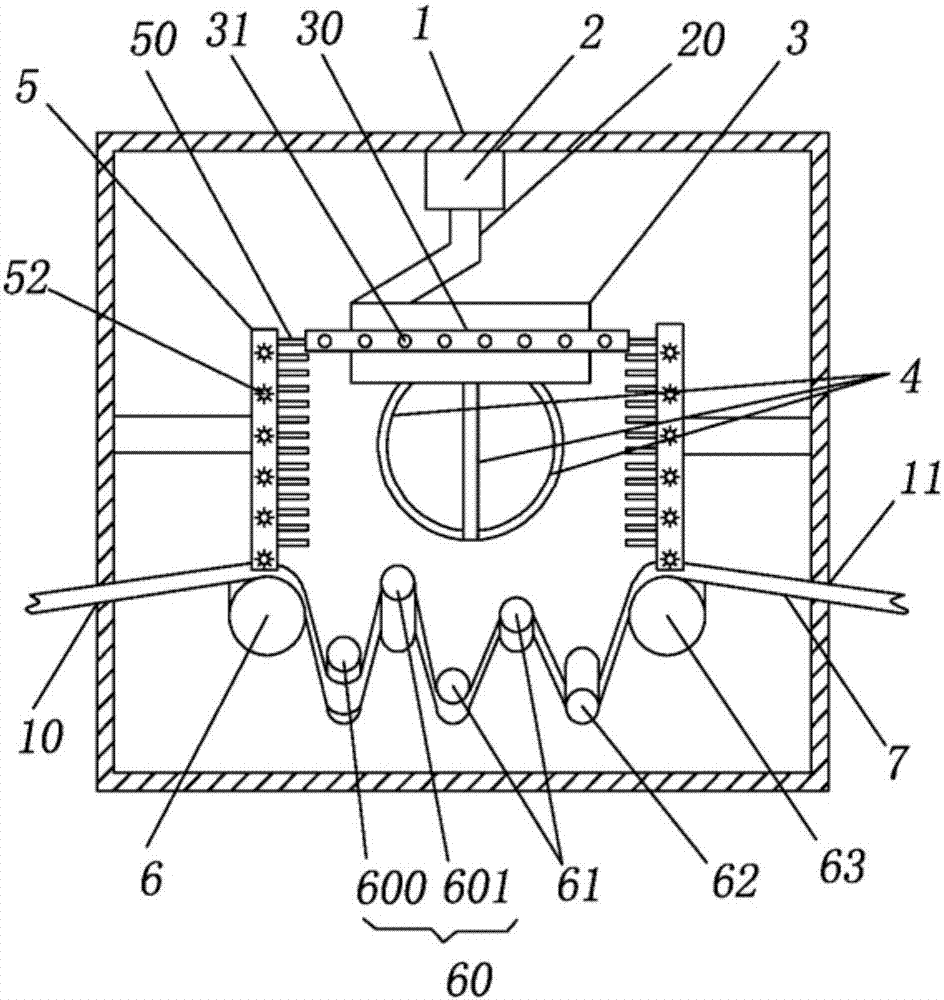

[0025] Step 1, preparation for sterilization: prepare a cuboid rack 1, such as figure 1 As shown, an ultraviolet lamp 4 driven by the motor 2 is installed on the frame 1, the wavelength of the ultraviolet rays emitted by the ultraviolet lamp 4 is preferably 254nm, and a hollow fabric for cleaning and sterilizing is respectively installed on both sides of the ultraviolet lamp 4 The cleaning disc 5 of 7, offers vent holes on the surface of the cleaning disc 5, and allows the cleaning disc 5 to rotate with the rotation of the ultraviolet lamp 4, and installs one for conveying the fabric 7 below the cleaning disc 5 and can turn the fabric 7 over. Surface drive roller set. The specific structure after installation is as follows: a feed port 10 is provided on the left side wall of the frame 1, and a discharge port 11 is provided on the right side wall. A motor 2, a rotating disc 3, an ultraviolet lamp 4,...

Embodiment 2

[0038] The difference between this embodiment and embodiment 1 is:

[0039] The wavelength of the ultraviolet light emitted by the ultraviolet lamp 4 in step one is preferably 260nm; the air pressure of ozone in the cleaning disc 5 in the step three is 1.2MPa; the rotating speed of the motor 2 in the step four is 500r / min; the rotating speed of the driving roller group and the winding roller Both are 150r / min; the diameter of the perforated hairs 521 is preferably 0.1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com