Image sensor and preparation method thereof

An image sensor, a part of the technology, is used in electric solid state devices, semiconductor devices, radiation control devices and other directions, which can solve the problems of inability to meet market demand, high risk of multi-camera assembly, and high cost, and achieves reduction of manufacturing costs, reduction of chip area, The effect of simplifying the difficulty of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

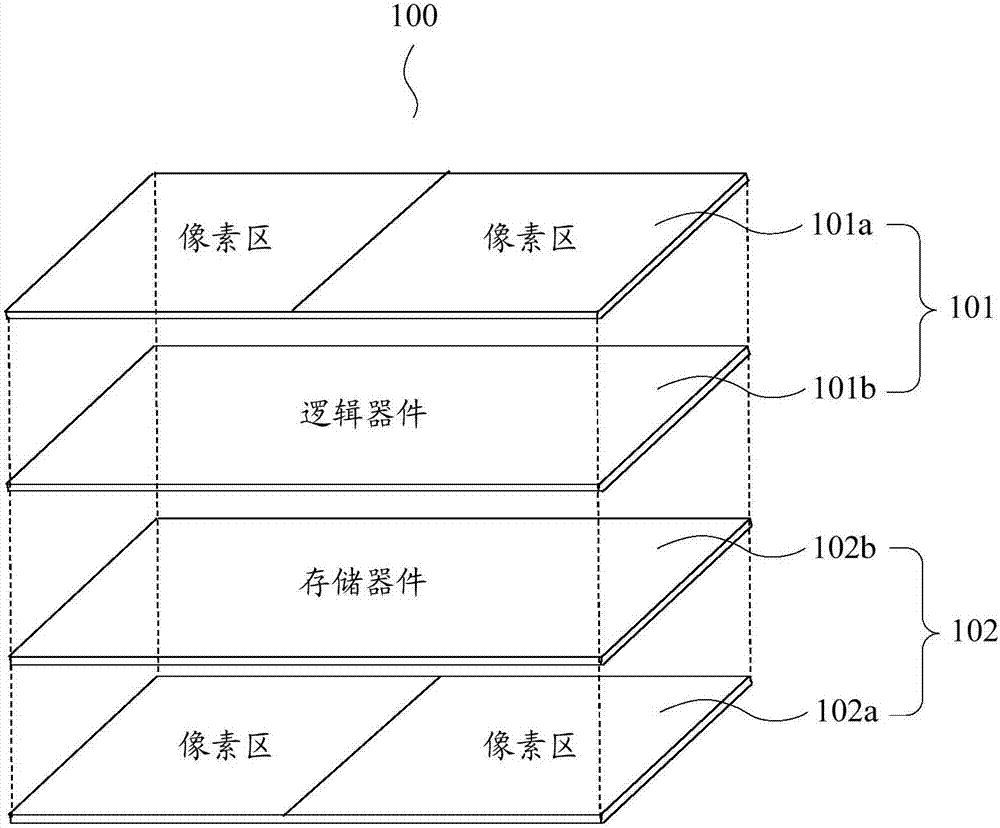

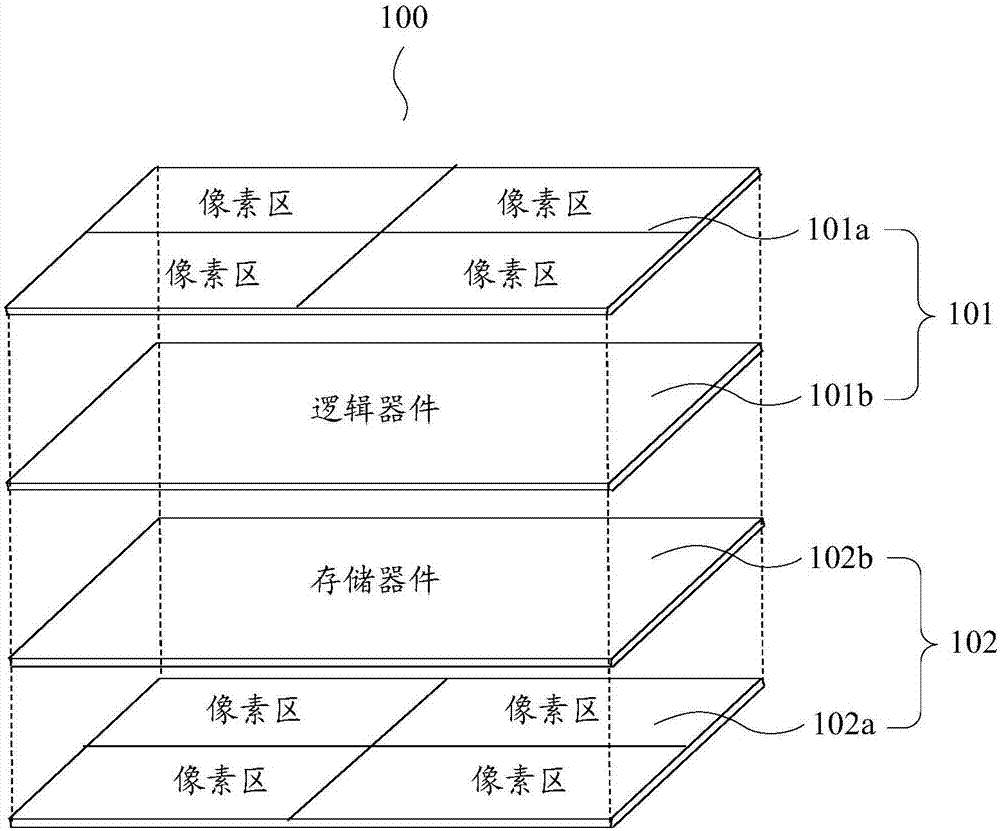

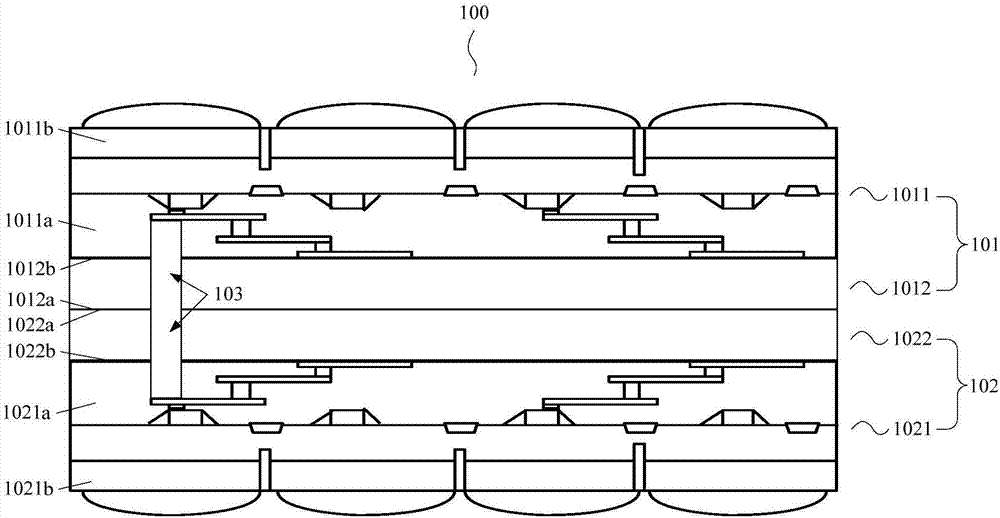

[0027] In order to solve the above technical problems, the technical solutions of the embodiments of the present invention provide an image sensor and a manufacturing method thereof, wherein the method includes: providing a first semiconductor substrate, and photosensitive pixels are formed on the front side of the first semiconductor substrate, and the The first semiconductor substrate is further formed with logic devices; a second semiconductor substrate is provided, and photosensitive pixels are formed on the front of the second semiconductor substrate; and the back of the first semiconductor substrate is bonded to the back of the second semiconductor substrate.

[0028] Those skilled in the art understand that the image sensor prepared by using the preparation scheme described in the embodiment of the present invention has a multi-layer structure, wherein the two outermost layers (ie, the front side of the first semiconductor substrate and the front side of the second semico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com