Universal sample introduction apparatus and universal sample introduction method for gaseous hydrocarbons and liquefied petroleum gas

A technology of liquefied petroleum gas and sampling device, which is applied in the direction of analysis materials and instruments, can solve the problems of poor repeatability of liquefied petroleum gas data results, incomplete gasification of liquefied petroleum gas, inaccurate quantification, etc. Quantification and quantification, overcoming the inaccuracy of liquid quantification, and ensuring the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

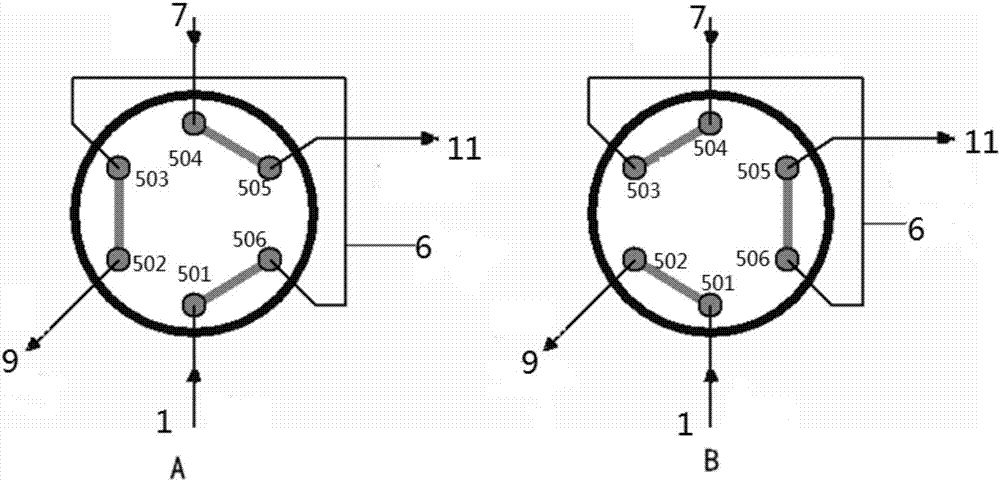

Embodiment 1

[0049] according to figure 1 The device measures the sulfur content of the liquefied petroleum gas sample, and the inlet 11 of the analyzer is connected to a sulfur content analyzer. Turn on the power of the instrument, check the connection of the pipeline, set the temperature of the gasification chamber 3 to 100°C, the temperature setting value can be adjusted according to the sample type, set the temperature of the quantitative loop 6 to 80°C, and set the temperature of the standard sample according to the Condition setting. After the temperature reaches the set value, the system is purged and the sampling loop 6 is filled. The volume of the quantitative loop is 3mL. Adjust the back pressure valve to stabilize the pipeline pressure at 3 kg. When the pressure is stable, switch the six-way valve and introduce the sample in the quantitative loop into the analyzer for analysis. The sulfur content read by the analyzer is 45.7 mg / m 3 , the repeated test result was 46.3mg / m 3 , ...

Embodiment 2

[0051] The test process is the same as in Example 1, except that the sample is not replaced, but the temperature of the vaporization chamber is set to 120°C. The two test results determined were 46.1mg / m 3 and 46.3mg / m 3 , which proves that the sample has been completely vaporized at 100°C, so the repeatability is good.

Embodiment 3

[0053] according to image 3 The device measures the sulfur content of the liquefied petroleum gas sample, and the inlet 11 of the analyzer is connected to a sulfur content detector. Turn on the power of the instrument, check the connection of the pipeline, set the temperature of the vaporization chamber 3 to 100°C, and set the temperature of the quantitative loop 6 to 60°C. After the temperature reaches the set value, the system is purged and the quantitative loop 6 sample filling process is carried out. The sample to be measured is a liquefied petroleum gas sample produced by a certain factory. The liquid sampling method is used. The volume of the quantitative loop after gasification is 3mL. Adjust the back pressure valve to stabilize the pipeline pressure at 3 kg. When the pressure is stable, switch the six-way valve to introduce the sample in the quantitative loop into the analyzer for analysis. The two test results determined were 126.1mg / m 3 and 125.3mg / m 3 , the test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com