Manufacture method of transparent tunnel model for simulating network containing complex fracture

A technology of tunnel model and fracture network, which is applied in the field of rock engineering, can solve the problems that it is difficult to accurately control the length and quantity of underground caverns, the accuracy of underground caverns cannot be accurately controlled, and the authenticity and accuracy of experimental results are affected. Prepare effects of different lengths, good brittleness, and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] It is planned to make a single tunnel model with a length of 100mm, a width of 100mm, and a height of 100mm. The specific manufacturing method is as follows:

[0049] (1) Prepare the frame mold of the tunnel model

[0050] Use 5 plexiglass plates to bond with an adhesive to make a cube-shaped box-shaped frame mold with an upper opening. In order to facilitate curing of the tunnel model, the size of the plexiglass plate is slightly larger than the actual size of the tunnel model. The size of the bottom plexiglass plate is 120X120mm , two side panels 120X110mm, the other two side panels 100X110mm, the thickness of the plexiglass plate is 10mm.

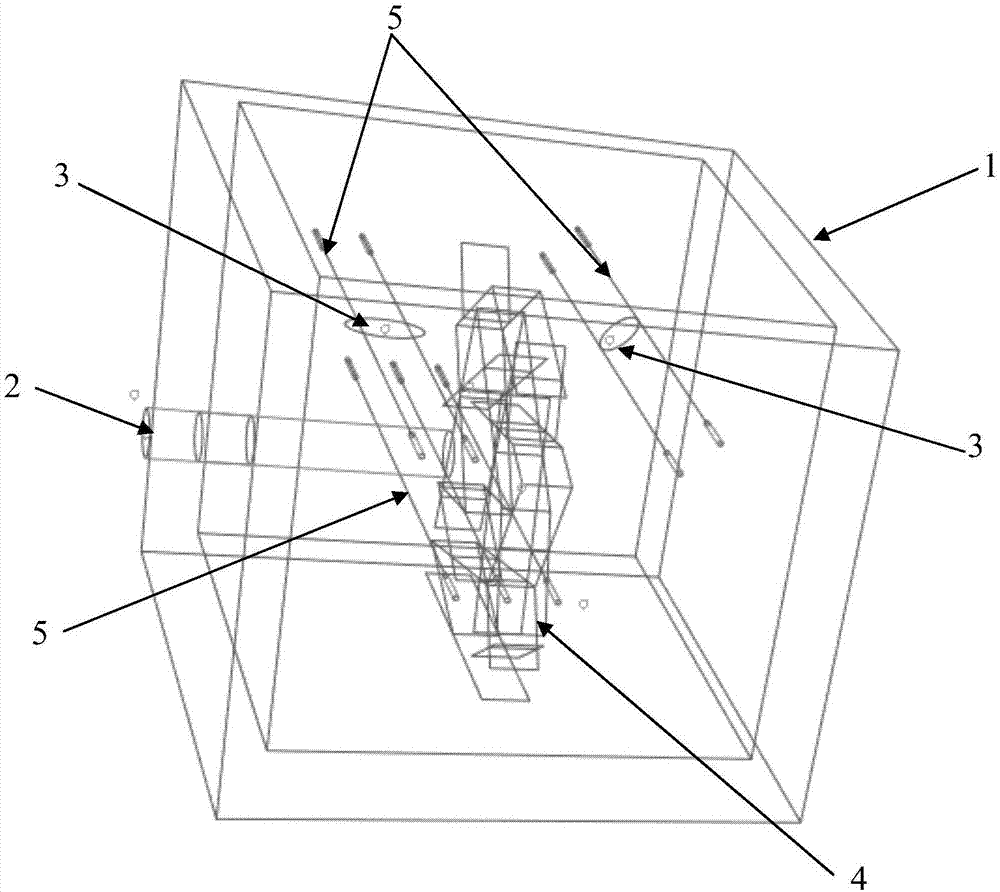

[0051] According to the relative positional relationship of the tunnel channel, the cracks in the surrounding rock and the complex crack network of the tunnel model to be prepared, the positioning of the tunnel channel model, crack model and complex crack model in the glass plate frame mold is pre-designed through CAD drawing, and...

Embodiment 2

[0064] It is planned to make two double tunnel models with a length of 100mm, a width of 100mm and a height of 100mm.

[0065] Preparation of frame mould, tunnel channel and fissure model, 3D printing preparation of complicated fissure model steps in the surrounding rock of the tunnel model are the same as in Example 1;

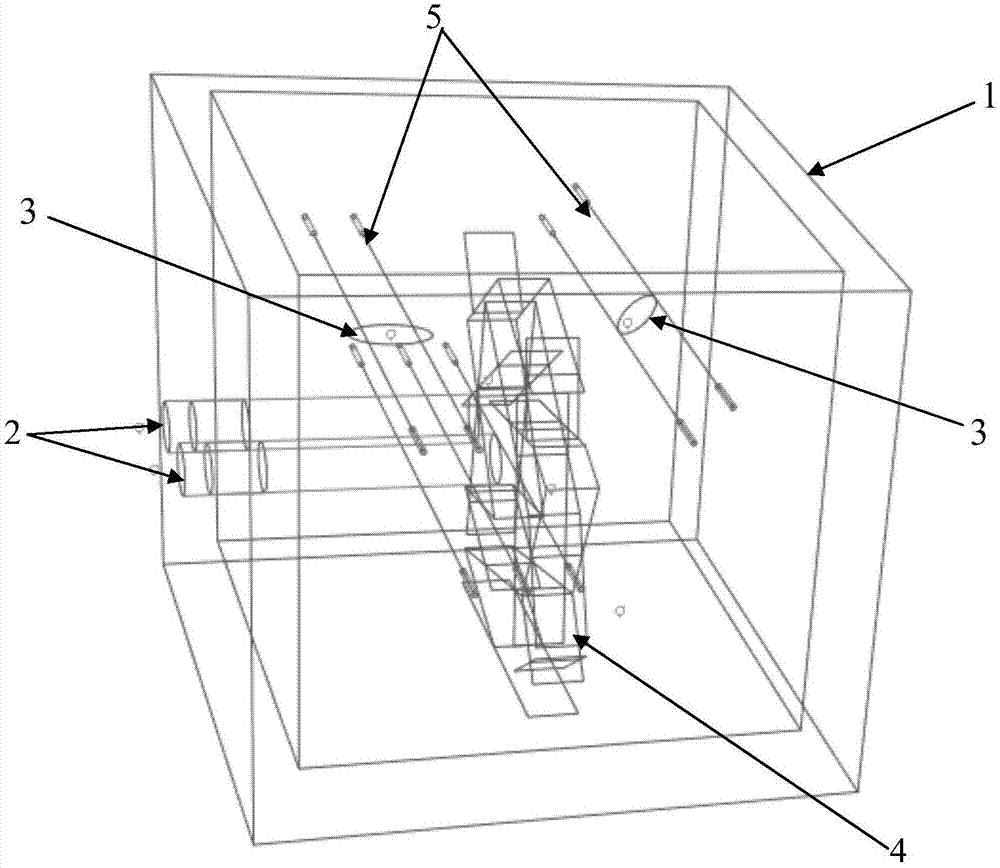

[0066] Positioning of the tunnel model, such as figure 2 As shown, according to the CAD drawing, use a soft cotton thread to pass through each positioning hole on the frame mold of the plexiglass plate and the complex crack model of the mica sheet and 3D printing in sequence, and connect the plexiglass tube, the mica sheet, and the complex crack model of the 3D printing The model is fixed at the positioning position of the tunnel channel model, crack model and complex crack model, and two plexiglass tubes with a length of 105mm are inserted into the plexiglass plate frame mold from the tunnel tunnel insertion holes on the plexiglass plate frame mold, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com