Manufacturing process of silastic checkered roll

A manufacturing process and silicone rubber technology, which is applied to the manufacturing process of silicone rubber pattern rollers, can solve the problems of complex pattern engraving process and low fidelity, and achieve the effects of high fidelity and advanced processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

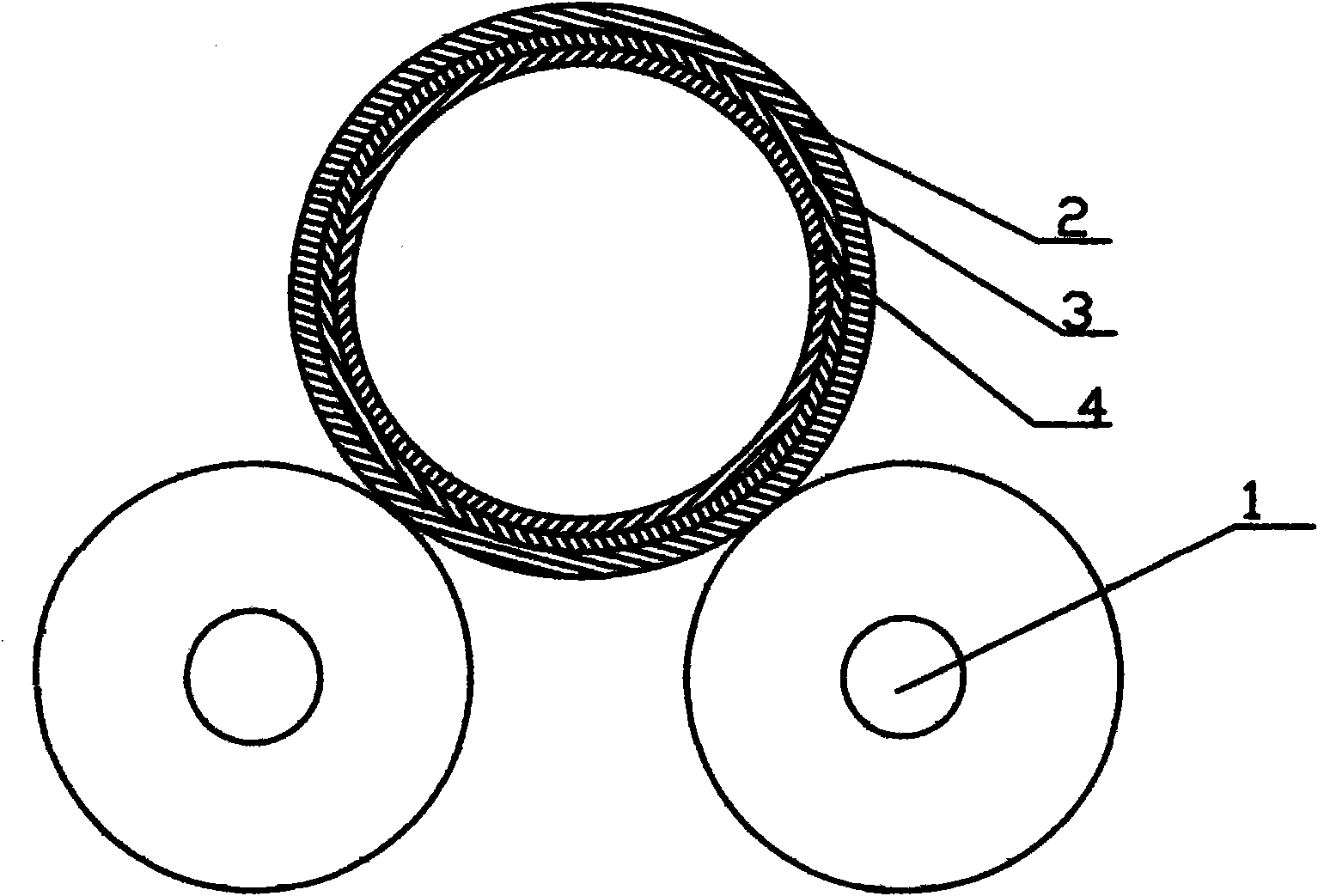

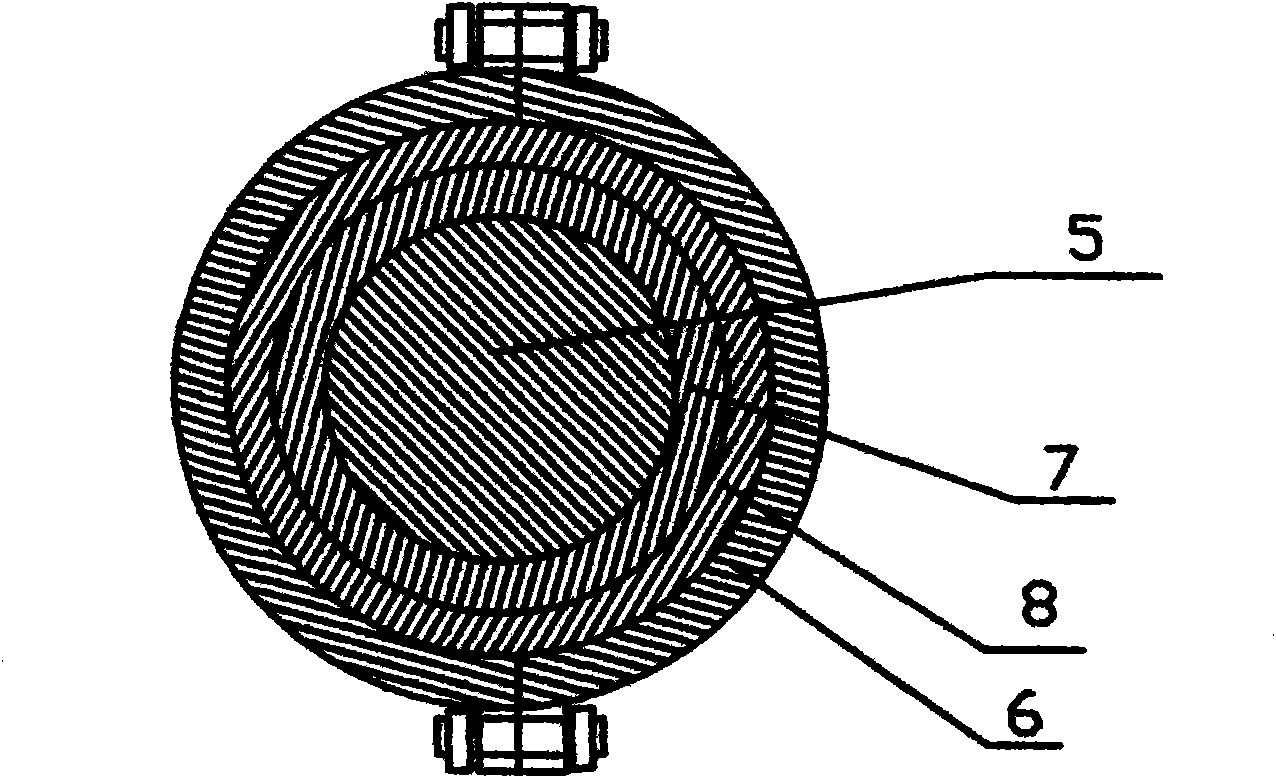

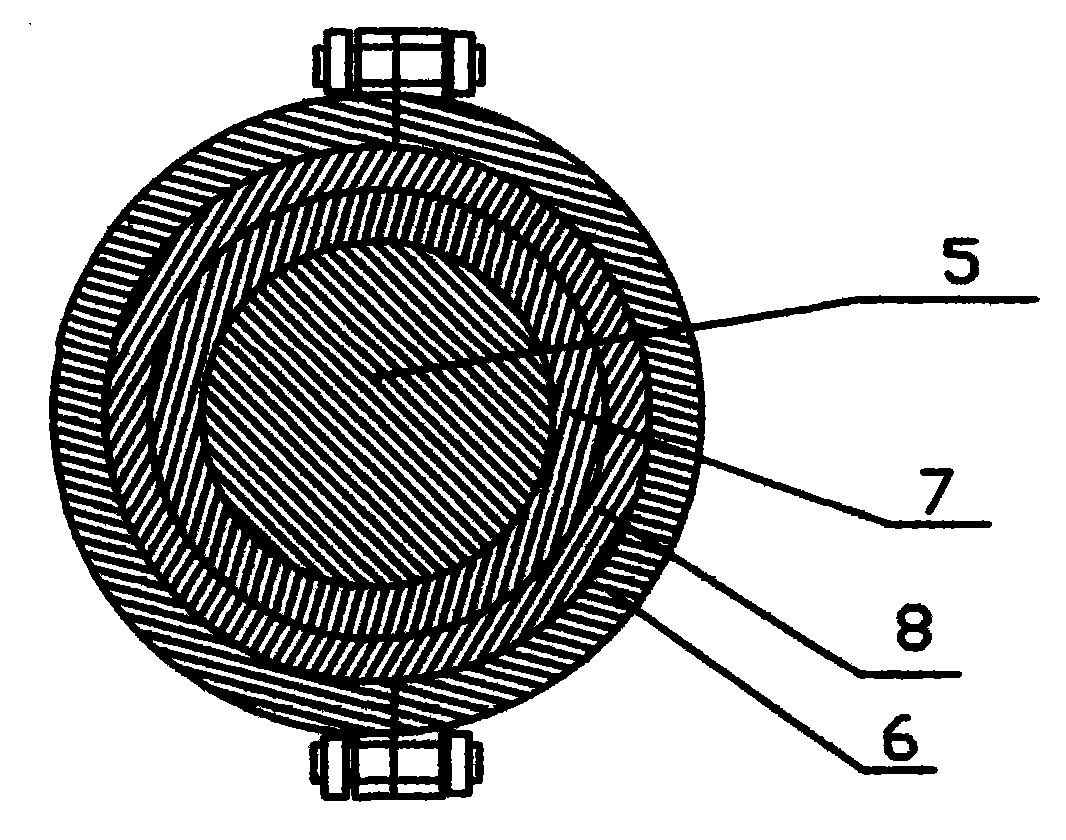

[0010] Silicone rubber pattern roller manufacturing process, the steps are as follows: the sample skin of animal or vegetable skin is coated with silicone rubber, after natural air drying, after peeling off the sample skin, the obtained silicone rubber block printed with the pattern on the sample skin is then coated with Coat resin on the silicone rubber block with sample skin pattern, obtain the blank mold, and then coat silicone rubber on the blank mold, splice the coated silicone rubber block into a cylindrical shape, and insert the processed cylindrical silicone rubber 3 Inside the centrifugal cylinder 2, the centrifugal cylinder 2 is driven by the following two transmission rollers 1, such as figure 1 As shown, and the pattern of the cylindrical silicone rubber faces inward, pour resin 4 on the surface of the pattern of the cylindrical silicone rubber, and the resin is generally epoxy resin. After rotating and centrifuging, it solidifies well, and after drying at 70-100°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com