Method of applying green chelating agent in paper pulp hydrogen peroxide bleaching

A hydrogen peroxide, chelating agent technology, applied in pulp bleaching, cellulose pulp post-processing, papermaking and other directions, can solve the problems of extended hazard range, difficult compounds, unfavorable human health, etc., to achieve environmental friendliness, improved tear index, The effect of excellent environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of method that green chelating agent is applied in bagasse pulp hydrogen peroxide bleaching, comprises the following steps:

[0026] 1) Chelation treatment (Q segment)

[0027] The Q section uses tetrasodium iminodisuccinate (IDS) as a chelating agent to carry out chelating treatment, specifically: adding tetrasodium iminodisuccinic acid to the bagasse pulp whose slurry concentration is 7wt% carries out chelating treatment as a chelating agent, Wherein, the consumption of tetrasodium iminodisuccinate (IDS) is 1 wt % of the dry pulp of bagasse pulp, the chelation temperature is 70° C., and the reaction time is 50 minutes.

[0028] 2) Hydrogen peroxide bleaching (P segment)

[0029] Step (1) gained bagasse pulp is added H 2 o 2 , NaOH, Na 2 SiO 3 , MgSO 4 Subsequent hydrogen peroxide bleaching is performed. Subsequent hydrogen peroxide bleaching process conditions: H 2 o 2 The amount of NaOH is 3% of the absolute dry pulp mass, the amount of NaOH is 2% of ...

Embodiment 2

[0034] A kind of method that green chelating agent is used in waste paper deinking pulp hydrogen peroxide bleaching, comprises the following steps:

[0035] 1) Chelation treatment (Q segment)

[0036] Section Q uses tetrasodium iminodisuccinate (IDS) as a chelating agent for chelating treatment, specifically: adding tetrasodium iminodisuccinate as a chelating agent to waste paper deinking pulp with a pulp concentration of 10 wt% Chelation treatment, wherein the amount of tetrasodium iminodisuccinate (IDS) is 1wt% of the dry pulp of waste paper deinking pulp, the chelation temperature is 80°C, and the reaction time is 50min.

[0037] 2) Hydrogen peroxide bleaching (P segment)

[0038] The waste paper deinked pulp obtained in step (1) is washed by inter-stage standards and then added with H 2 o 2 , NaOH, Na 2 SiO 3 , MgSO 4 Subsequent hydrogen peroxide bleaching is performed. Subsequent hydrogen peroxide bleaching process conditions: H 2 o 2 The amount of NaOH is 3% of ...

Embodiment 3

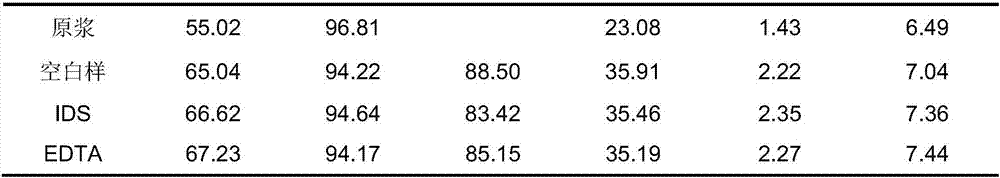

[0043] The comparative experiment of bagasse pulp IDS chelation and EDTA chelation comprises the following steps:

[0044] 1) Chelation treatment (Q segment)

[0045]The Q section uses tetrasodium iminodisuccinate (IDS) as a chelating agent to carry out chelating treatment, specifically: adding tetrasodium iminodisuccinic acid to the bagasse pulp of 5wt% in slurry concentration as a chelating agent to carry out chelating treatment, Wherein, the dosage of tetrasodium iminodisuccinate (IDS) is 0.8wt% of the dry pulp of bagasse pulp, the chelating temperature is 70° C., and the reaction time is 60 minutes.

[0046] 2) Hydrogen peroxide bleaching (P segment)

[0047] Step (1) gained bagasse pulp is added H 2 o 2 , NaOH, Na 2 SiO 3 , MgSO 4 Subsequent hydrogen peroxide bleaching is performed. Subsequent hydrogen peroxide bleaching process conditions: H 2 o 2 The amount of NaOH is 3% of the absolute dry pulp mass, the amount of NaOH is 2% of the absolute dry pulp mass, NaOH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com