A kind of preparation method of engine cover

An engine cover and generating agent technology, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of high temperature and humidity requirements, difficulty in ensuring thickness uniformity, and affecting the user's appearance and feeling, etc. Achieve the effect of high production efficiency, high qualification rate, low requirements and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] The invention provides a method for preparing an engine cover.

[0076]

[0077] A kind of preparation method of engine cover, such as figure 1 As shown, it includes the following steps:

[0078] (1) Inject the skin forming agent from the closed sprue of the upper mold of the first mold into the cavity of the first mold, cure for 60-90s, and then open the upper mold of the first mold and the lower mold of the first mold , to obtain the upper cortex 1 with a wavy surface;

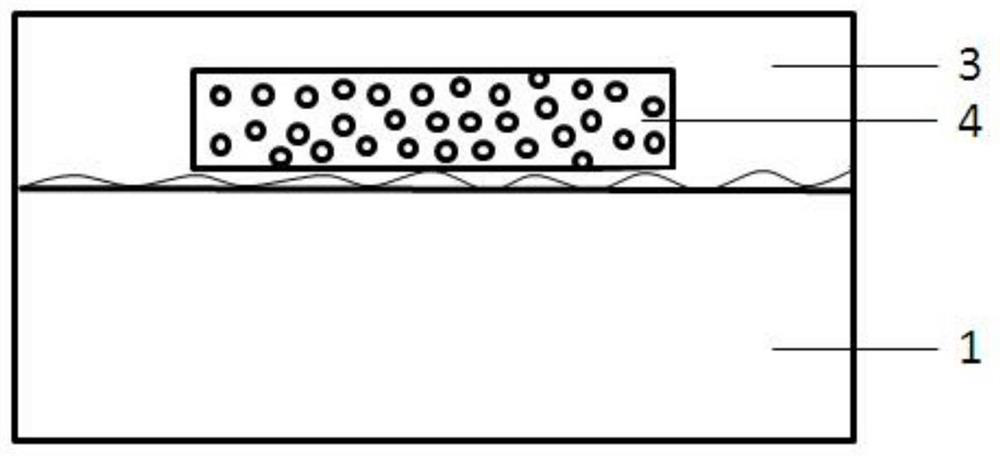

[0079] (2), place the non-wavy surface of the cortex 1 with the wavy surface on the inner bottom surface of the second mold, make the non-wavy surface contact with the inner bottom surface, and have the cortex 1 wave of the wavy surface at the top Place the micro-perforated plate 2 with a support on the surface, then pour the foam layer generator on the corrugated surface of the cortex 1 with a corrugated surface and the micro-perforated plate 2 with a support to form a foam layer 3, and close the...

Embodiment 1

[0156] The present embodiment provides a kind of preparation method of engine cover, as figure 1 As shown, it includes the following steps:

[0157] (1) Inject the skin forming agent from the sprue of the upper mold of the closed first mold (the injection pressure is 11MPa) into the cavity of the first mold, solidify for 60s, and then open the upper mold of the first mold and the second mold. A lower mold of a mold, to obtain a cortex 1 with a wavy surface on the upper part;

[0158] (2), place the non-wavy surface of the cortex 1 with the wavy surface on the inner bottom surface of the second mold, make the non-wavy surface contact with the inner bottom surface, and have the cortex 1 wave of the wavy surface at the top Place the micro-perforated plate 2 with support on the surface, then pour (the pressure of pouring is 11MPa) foam layer generator to be formed foam layer 3, and close the upper mold of the second mold and the lower mold of the second mold to carry out foam mo...

Embodiment 2

[0213] The present embodiment provides a kind of preparation method of engine cover, as figure 2 As shown, it includes the following steps:

[0214] (1) Inject the skin forming agent from the sprue of the closed upper mold of the first mold (the injection pressure is 11MPa) into the cavity of the first mold, solidify for 90s, and then open the upper mold of the first mold and the second mold. A lower mold of a mold, to obtain a cortex 1 with a wavy surface on the upper part;

[0215] (2), place the non-wavy surface of the cortex 1 with the wavy surface on the inner bottom surface of the second mold, make the non-wavy surface contact with the inner bottom surface, and have the cortex 1 wave of the wavy surface at the top Place the micro-perforated plate 4 on the shaped surface, then pour (the pressure of pouring is 11MPa) foam layer generating agent on the wavy surface of the cortex 1 with the wavy surface and the micro-perforated plate 4 to form the foam layer 3, and close t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com