Direct-type backlight module and liquid crystal display device thereof

A backlight module, direct type technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of light source and lens occupying space, large thickness of direct type backlight module, etc., to achieve thin design and reduce thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

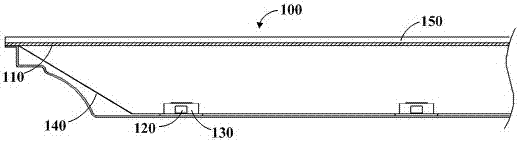

[0015] Based on the related technology, when the direct-type backlight module is working, it needs to realize the uniformity of the outgoing light through a certain light mixing distance, the refraction effect of the lens and the scattering effect of the diffusing agent on the light, so the light mixing distance, the light source The space occupied by the lens and the lens leads to a large thickness of the direct-type backlight module, which is not conducive to the thinning trend of the display device.

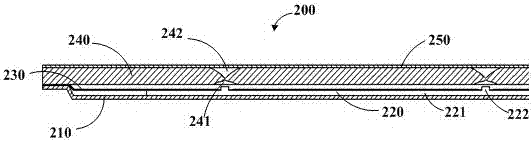

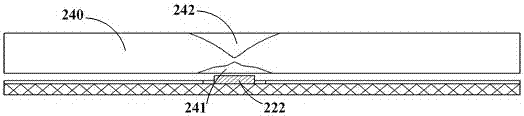

[0016] Therefore, the present application proposes a direct-lit backlight module, in which a light guide plate is used, and a tapered groove corresponding to the LED light is provided on the light incident surface of the light guide plate and a conical concave groove is provided on the light exit surface. The inverted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com