Macromolecule nonmetal energy oil unstressed container pulse steam method and pulse steam engine

A non-metal and polymer technology, applied in the field of pulsating steam generation, can solve the problems of large environmental pollution, large energy consumption, high energy consumption, etc., and achieve the effects of environmental protection manufacturing cost, uniform exchange temperature, and high thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

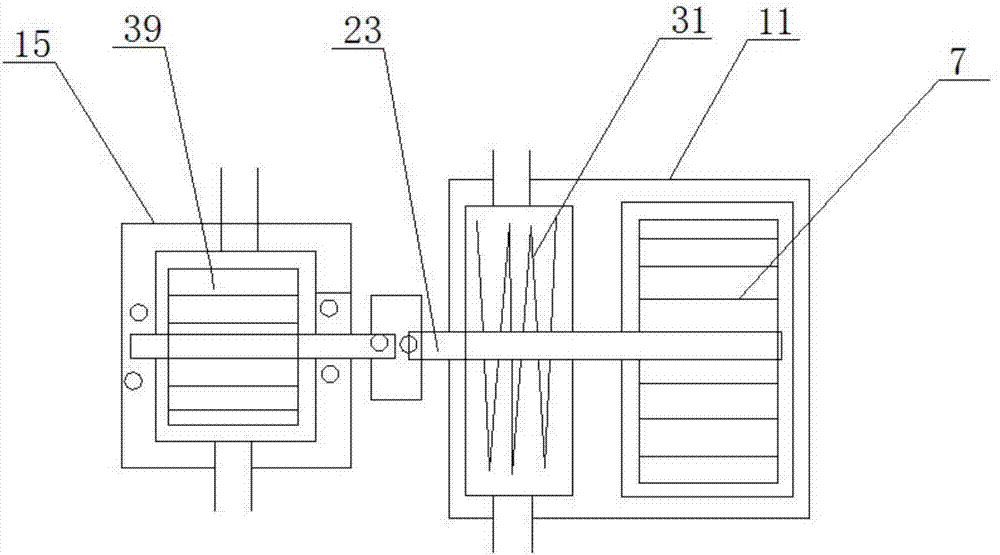

Image

Examples

Embodiment approach

[0024] As a preferred embodiment of the present invention, the direct evaporation porous distribution pipe 9 is provided with a water inlet pipe 12 , and the other end of the water inlet pipe 12 is provided with a high-pressure water pump 33 .

[0025] As a preferred embodiment of the present invention, the oil cylinder 35 is provided with an inspection port 10 , and the inspection port 10 is provided with an observation hole 8 .

[0026] As a preferred embodiment of the present invention, the air mixer 3 is provided with an air inlet 3-1.

[0027] As a preferred embodiment of the present invention, the bottom of the right circulation pump 18 is connected to the oil cylinder 35 through the second flow guide pipe 19 , and the top of the right circulation pump 18 is connected to the pulsating evaporator 32 through the second high temperature flow guide pipe 34 .

[0028] As a preferred embodiment of the present invention, the control system 30 is connected to the high-pressure w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com