Lining construction method and lining trolley thereof

A technology of lining trolley and construction method, which is applied in shaft lining, tunnel lining, earthwork drilling and mining, etc., can solve the problems of concrete disturbance, potential safety hazards, and low construction efficiency, so as to reduce labor intensity and safety risks, and improve Pouring quality and efficiency, and the effect of reducing personnel input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

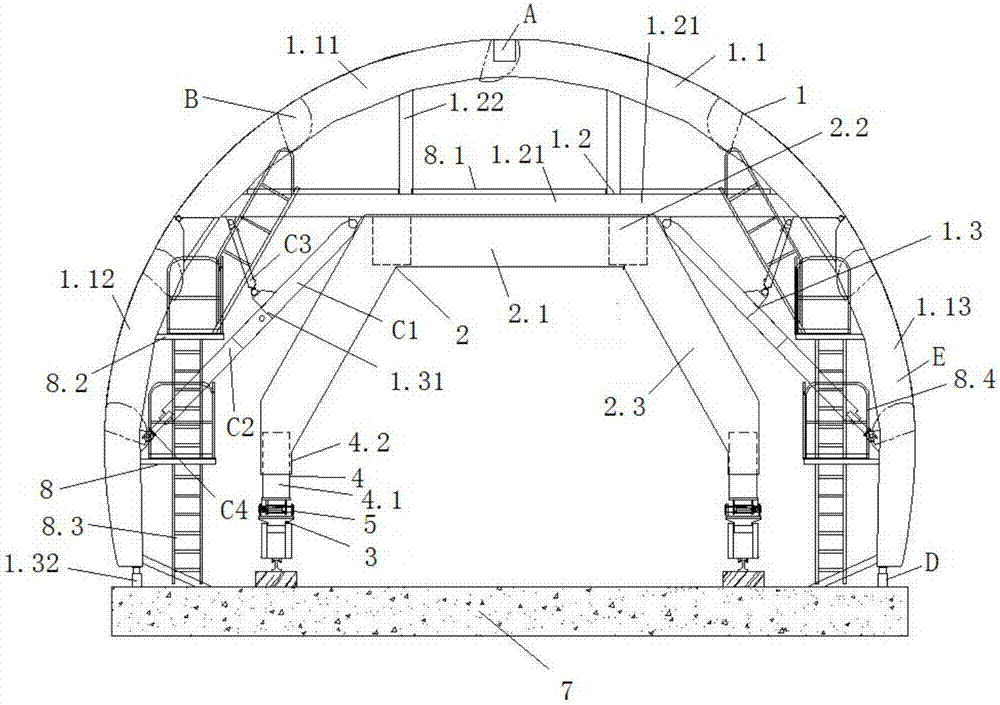

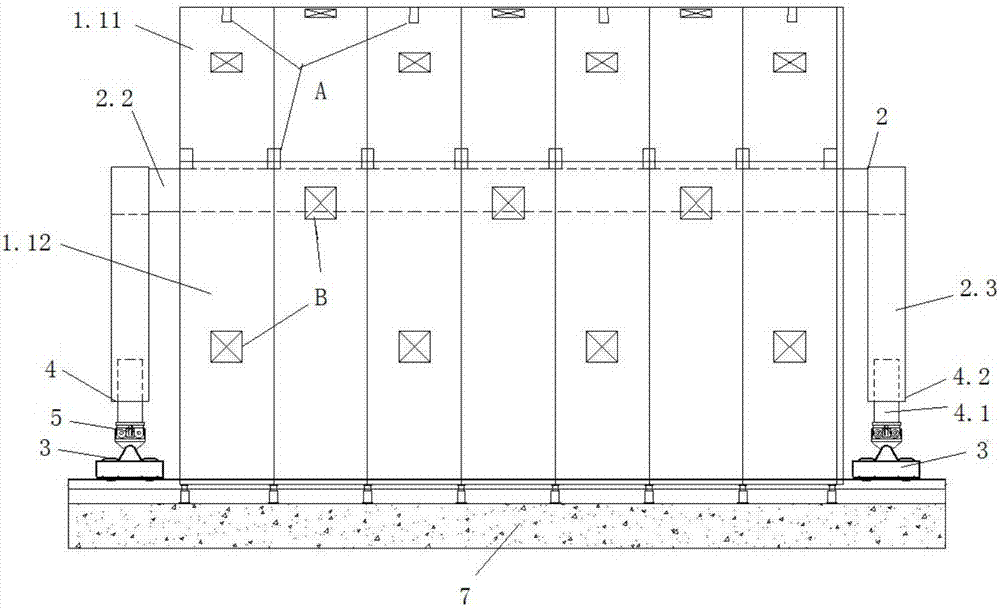

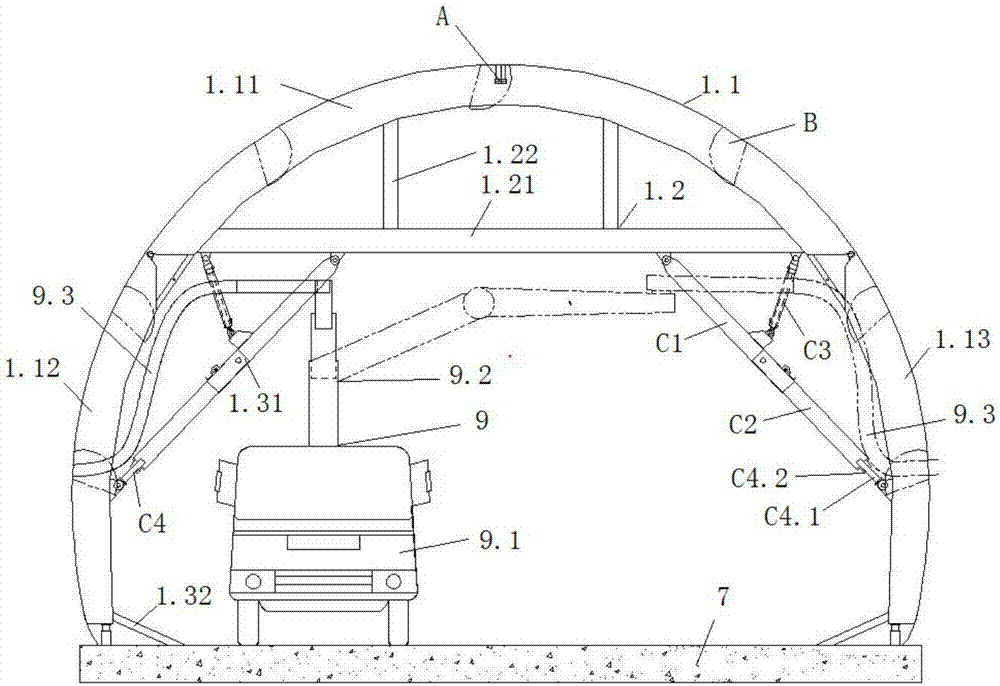

[0059] A lining trolley, including a formwork system 1, a door frame system 2 and a traveling mechanism 3, see Figure 1-Figure 5 , the formwork system 1 includes a group of formwork system individual pieces or at least two groups of formwork system individual pieces with the same structure, the portal frame system 2 is independently or detachably connected to the formwork system individual pieces, and the portal frame The combination of system 2 and running gear 3 is used to carry the formwork system single piece, transport the formwork system single piece to the corresponding construction site and adjust the formwork system single piece to match the lining surface of the tunnel to be lined; The formwork system unit is a load-bearing component during lining construction, and the formwork system unit is connected to the portal system 2 and the construction ground 7; the traveling mechanism 3 is used to drive the portal system 2 to move. The combination of a single gantry syste...

Embodiment 2

[0093] The difference between this embodiment and Embodiment 1 is that: the walking mechanism 3 includes walking parts, and the walking parts include two sets of walking units arranged side by side; the gantry longitudinal beam group 2.2 includes four The gantry longitudinal beams arranged side by side, the two gantry beams and the two gantry longitudinal beams above form a gantry skeleton structure with a quadrilateral cross-section on the horizontal plane, and the upper ends of the four gantry columns They are all connected to the four corners of the gantry frame structure; the two ends of the two gantry longitudinal beams located below are respectively connected to the lower ends of the two gantry columns arranged side by side along the length direction of the lining trolley; The walking single piece is arranged on the longitudinal beam of the door frame located below, and the walking single piece and the longitudinal beam of the door frame are arranged in one-to-one corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com