Beta-hydroxyl-beta-methyl calcium butyrate preparation method

A technology of calcium methyl butyrate and methyl butyric acid, applied in the field of nutritional fortifiers, can solve the problems of non-conformity with green chemistry, high cost, pollution, etc., and achieves a synthesis method with high efficiency and environmental protection, broad market prospects, and mild reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

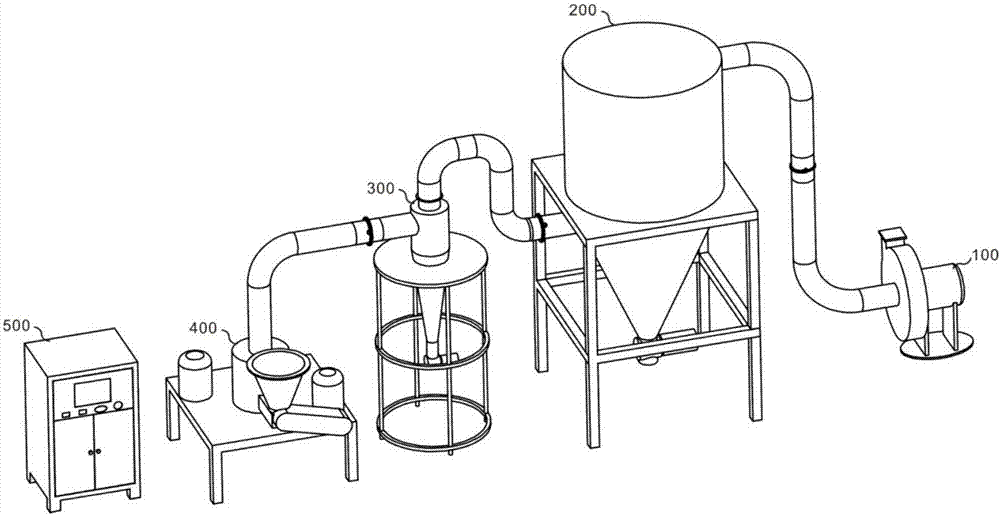

[0041] Mix 200ml of sulfuric acid solution with a mass concentration of 10% with 2000ml of glacial acetic acid and 6000ml of hydrogen peroxide with a mass concentration of 30%, and react at 45°C for 10min, during which the stirring speed is 200rpm. Fraction, obtain 2500ml of peracetic acid aqueous solution, mix it with 1250ml of diacetone alcohol, add 2000ml of methyl acetate, react at 30°C for 1h, during which the stirring speed is 100rpm, distill and collect the fraction at 70°C to obtain methyl acetate, The substance after distillation is β-hydroxy-β-methylbutyric acid solution, add water 2500ml therein, then add sodium hydroxide solution to adjust to pH 6.0, filter after heating to dissolve, take filtrate and add 1000g calcium chloride. Stir and react at 400rpm for 20min, add sodium hydroxide to adjust the pH to 6.5, precipitate β-hydroxyl-β-methylbutyrate calcium, filter, and dry to obtain β-hydroxyl-β-methylbutyrate calcium 1704g. It is put into the feeding system 600, e...

Embodiment 2

[0043]Mix 200ml of 10% sulfuric acid solution with 1800ml of glacial acetic acid and 5400ml of 30% hydrogen peroxide at 50°C for 12 minutes with a stirring speed of 250rpm. Fraction, obtain 1900ml of peracetic acid aqueous solution, mix it with 1100ml of diacetone alcohol, add 2000ml of methyl acetate, react at 35°C for 70min, during which the stirring speed is 120rpm, distill and collect the fraction at 70°C to obtain methyl acetate, The substance after distillation is β-hydroxy-β-methylbutyric acid solution, add water 2100ml to it, then add sodium hydroxide solution to adjust the pH to 6.0, heat to dissolve and filter, take the filtrate and add 1000g calcium chloride. Stir and react at 450rpm for 30min, add sodium hydroxide to adjust the pH to 6.5, precipitate β-hydroxyl-β-methylbutyrate calcium, filter, and dry to obtain β-hydroxyl-β-methylbutyrate calcium 1690g. It is put into the feeding system 600, enters the crushing system 500 for crushing, and then is collected by the...

Embodiment 3

[0045] Mix 200ml of sulfuric acid solution with a mass concentration of 10%, 2000ml of glacial acetic acid, and 5000ml of hydrogen peroxide with a mass concentration of 30%, and react at 40°C for 10min, during which the stirring speed is 200rpm. Fraction, obtain 1800ml of peracetic acid aqueous solution, mix it with 900ml of diacetone alcohol, add 1600ml of methyl acetate, react at 25°C for 50min, the stirring speed is 120rpm, distill and collect the cut at 70°C to obtain methyl acetate, The substance after distillation is β-hydroxy-β-methylbutyric acid solution, add water 2300ml to it, then add sodium hydroxide solution to adjust the pH to 6.0, heat to dissolve and filter, take the filtrate and add 1000g calcium chloride. Stir and react at 350rpm for 30min, add sodium hydroxide to adjust the pH to 6.5, and precipitate β-hydroxyl-β-methylbutyrate calcium, filter, and dry to obtain β-hydroxyl-β-methylbutyrate calcium 1650g. It is put into the feeding system 600, enters the crus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com