Automatic wet-process sorting control method for waste glass

An automatic sorting and control method technology, applied in sorting, chemical instruments and methods, magnetic separation, etc., can solve the problems of extensive sorting in the recycling process, low degree of mechanization and automation in the processing and utilization process, and lack of economic benefits of processing scale. , to achieve the effect of improving sorting quality, sorting efficiency and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

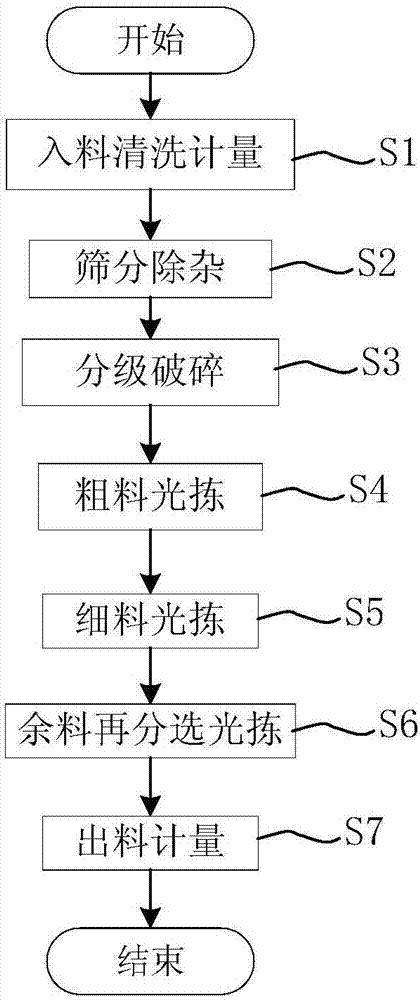

[0022] figure 1 It is a schematic diagram of the waste glass wet automatic sorting process of the present invention.

[0023] See figure 1 , the waste glass wet automatic sorting control method provided by the present invention, which includes the following steps:

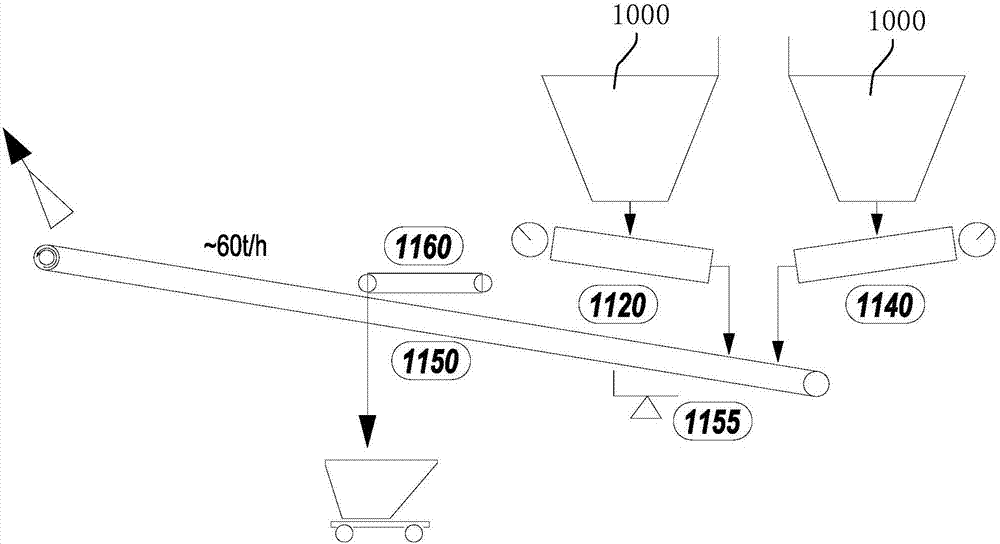

[0024] S1: Feeding, cleaning and metering: After cleaning and dewatering the waste glass, the vibrating feeder is used to feed the materials, and the materials passing through the feeder are evenly sent to the metering conveyor belt, and the whole bottle and broken glass are sent to the cross On the distributing machine and rod screening machine, the feeding speed of the bin and the feeding speed of the vibrating distributing machine can be adjusted through the metering conveyor belt.

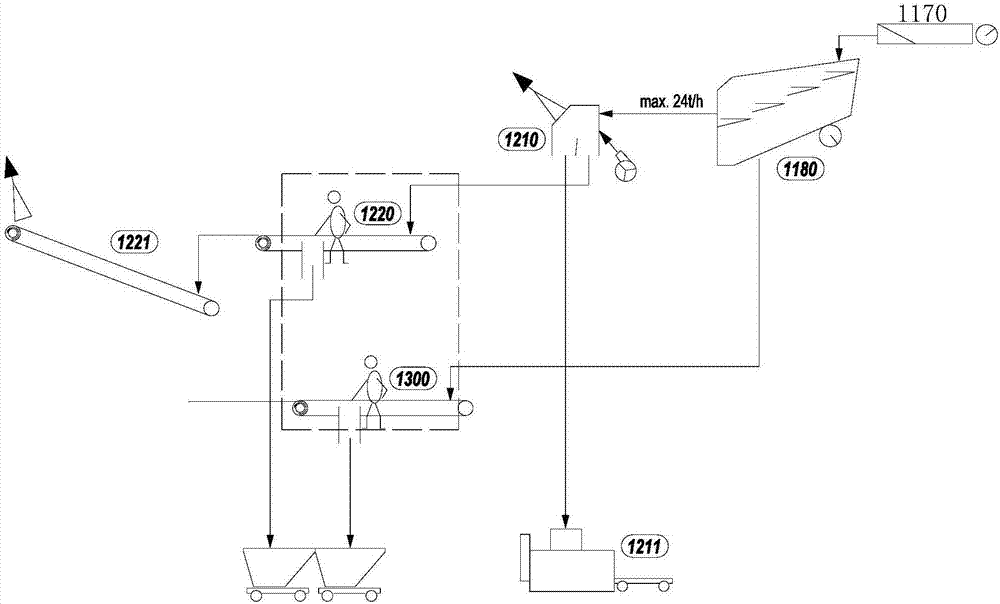

[0025] S2: Screening and impurity removal: The cross feeder evenly transfers the material to the bar si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com