Stable storage indapamide sustained release tablet and preparing process thereof

A technology of indapamide and sustained-release tablets, applied in the field of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

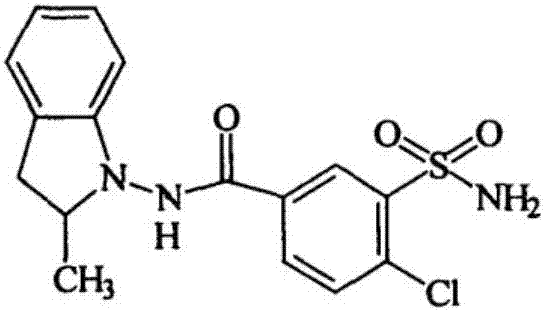

Image

Examples

Embodiment 1

[0024] The composition is as follows in Table 1:

[0025] Table 1

[0026] Raw materials

Batch: 1000 pieces

1.5g

124.5g

Hypromellose 4000cps

72g

Micropowder silica gel

1g

1g

[0027] Preparation:

[0028] (1) Initial mixing: the prescription amount of indapamide and lactose mixed;

[0029] (2) Sieve: sieve the above-mentioned mixed material with 30 meshes;

[0030] (3) Mixing: after sieving, the material is evenly mixed with hypromellose 4000cps;

[0031] (4) final mixing: the above-mentioned mixed material is mixed with micropowder silica gel and magnesium stearate;

[0032] (5) Tabletting: The above materials are pressed into tablets with a punching die of No. Φ8.

Embodiment 2

[0034] The composition is as shown in Table 2:

[0035] Table 2

[0036] Raw materials

Batch: 1000 pieces

Indapamide

1.5g

123.5g

Hypromellose 4000cps

72g

hydrogenated castor oil

3g

[0037] Preparation:

[0038] (1) initial mixing: the indapamide and microcrystalline cellulose of prescription quantity are mixed;

[0039] (2) Sieve: 24 meshes of above-mentioned mixed materials are sieved;

[0040] (3) Mixing: after sieving, the material is evenly mixed with hypromellose 4000cps;

[0041] (4) final mixing: above-mentioned mixed material is mixed with hydrogenated castor oil;

[0042] (5) Tabletting: The above materials are pressed into tablets with a punching die of No. Φ8.

Embodiment 3

[0044] The composition is as follows in Table 3:

[0045] table 3

[0046] Raw materials

Batch: 1000 pieces

Indapamide

1.5g

127.5g

68g

talcum powder

1g

hydrogenated castor oil

2g

[0047] Preparation:

[0048] (1) Initial mixing: the prescription amount of indapamide and lactose mixed;

[0049] (2) Sieve: sieve the above-mentioned mixed material with 30 meshes;

[0050] (3) Mixing: after sieving, the material is evenly mixed with hydroxypropyl cellulose HXF;

[0051] (4) Final mixing: the above-mentioned mixed material is mixed with talcum powder and hydrogenated castor oil; (5) Tabletting: the above-mentioned material is pressed into a tablet with a die of Φ8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com