Polyamic acid solution composition and polyimide film

A technology of polyimide film and polyamic acid, which is applied in coatings, printed circuit components, printed circuits, etc., can solve problems such as lack of flexibility, glass fragility, and insufficient glass strength, and achieve small phase difference and excellent durability. thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

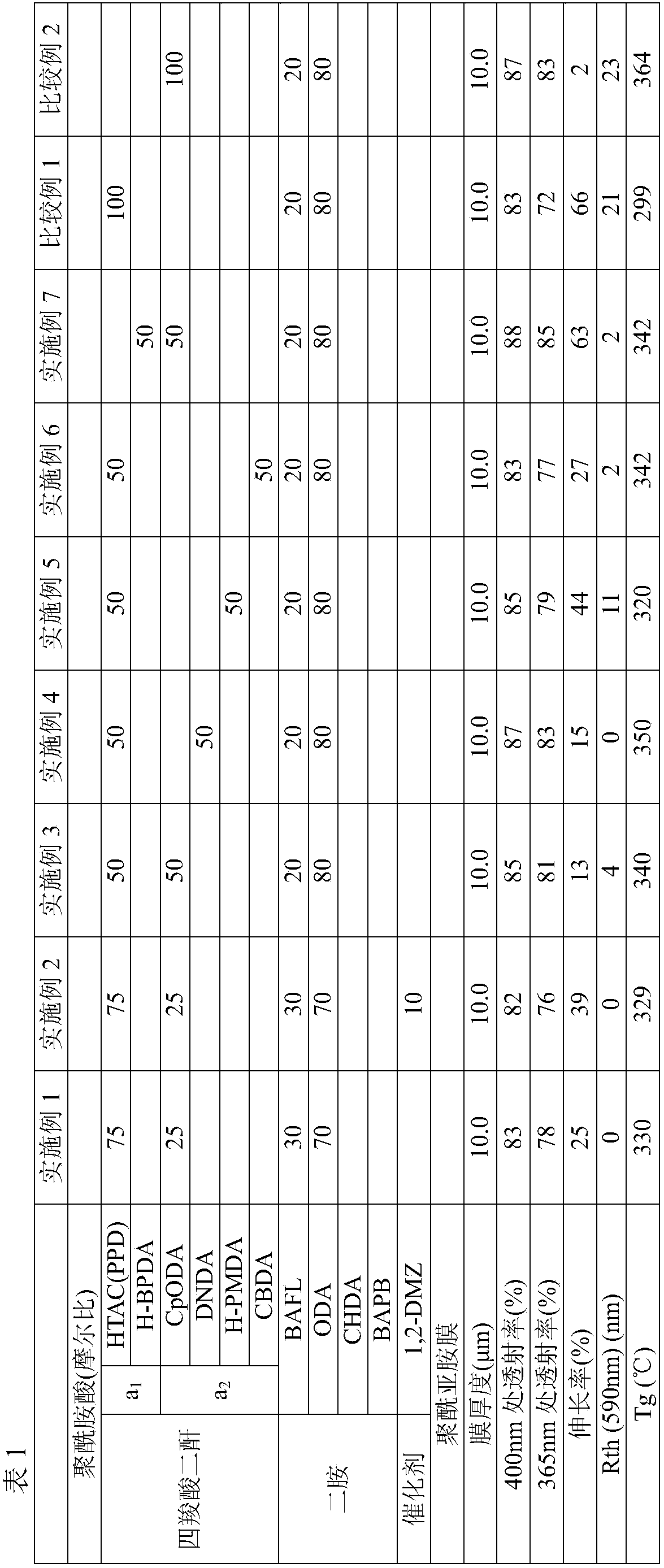

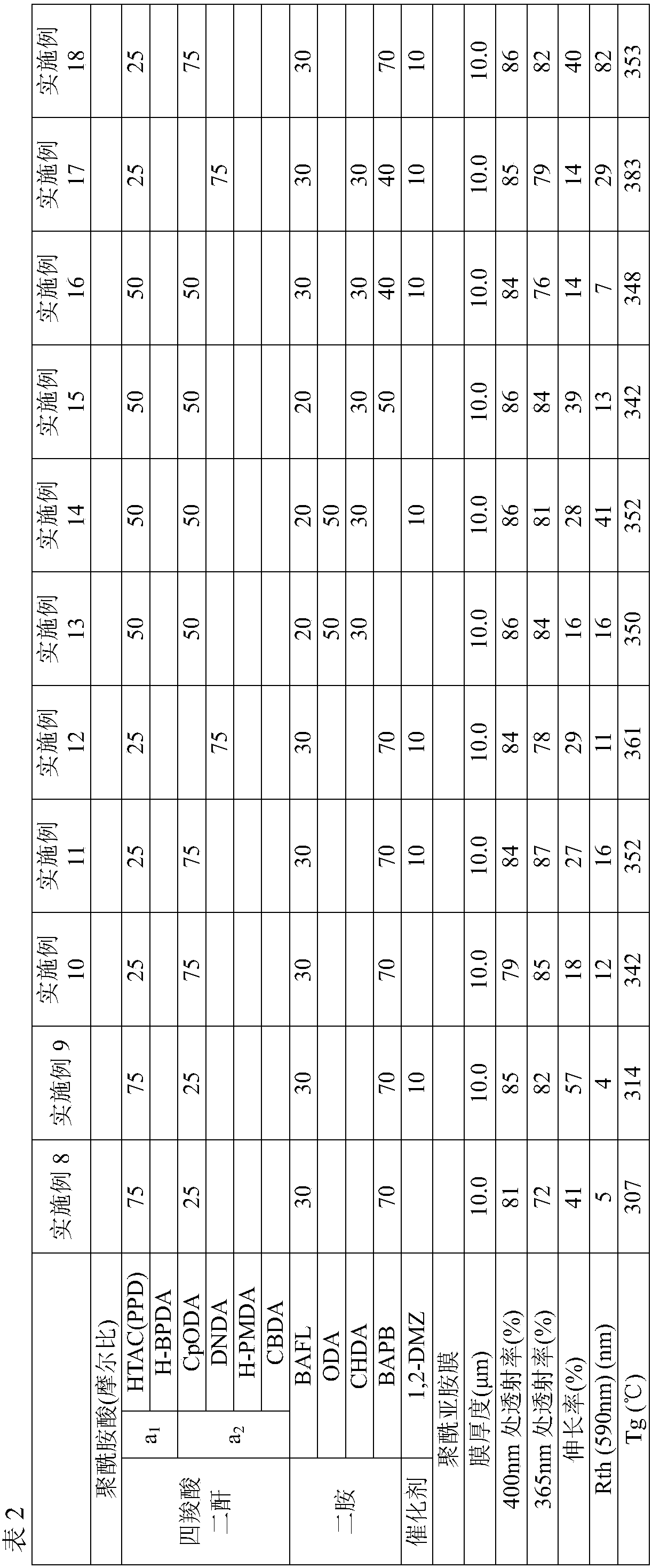

[0101] Into a 500 mL (inner volume) glass reactor equipped with a stirrer and a nitrogen filling / discharging tube was placed 420 g of N-methyl-2-pyrrolidone as a solvent. Then 16.1910 g (0.0809 mol) ODA, 12.0734 g (0.0347 mol) BAFL, 11.0990 g (0.0289 mol) CpODA and 40.5803 g (0.0866 mol) HTAC (PPD) were added thereto, and the mixture was stirred at 50° C. to obtain A polyamic acid solution with a solid content of 15.17%.

[0102] The polyamic acid solution was coated on a glass plate as a substrate with a wire bar coater. The coating film was heated from 50° C. to 350° C. at a rate of temperature increase of 10° C. / minute in a nitrogen atmosphere, and then heated at 350° C. for 5 minutes to form a polyimide film having a thickness of 10 μm on a glass plate.

[0103] The obtained polyimide film was peeled off from the glass plate, and various properties were measured. The results are shown in Table 1.

Embodiment 2

[0105] Into a 500 mL (inner volume) glass reactor equipped with a stirrer and a nitrogen filling / discharging tube was placed 420 g of N-methyl-2-pyrrolidone as a solvent. To this was then added 16.1910 g (0.0809 mol) ODA, 12.0734 g (0.0347 mol) BAFL, 11.0990 g (0.0289 mol) CpODA, 40.5803 g (0.0866 mol) HTAC (PPD) and 1.1105 g (0.0116 mol) 1,2-DMZ , and the mixture was stirred at 50° C. to obtain a polyamic acid solution with a solid content of 15.17%.

[0106] A polyimide film was formed in the same manner as in Example 1 except that this polyamic acid solution was used, and various properties were measured. The results are shown in Table 1.

Embodiment 3

[0108] Into a 500 mL (inner volume) glass reactor equipped with a stirrer and a nitrogen filling / discharging tube was placed 420 g of N-methyl-2-pyrrolidone as a solvent. Then 19.5454 g (0.0976 mol) ODA, 8.5019 g (0.0244 mol) BAFL, 23.4472 g (0.0610 mol) CpODA and 28.5761 g (0.0610 mol) HTAC (PPD) were added thereto, and the mixture was stirred at 50°C to obtain a solid A polyamic acid solution with a content of 15.12%.

[0109] A polyimide film was formed in the same manner as in Example 1 except that this polyamic acid solution was used, and various properties were measured. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com