Motor stator immersion painting process

A technology of motor stator and dipping paint, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve problems such as unevenness and uneven stator paint film, and achieve the effect of improving insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

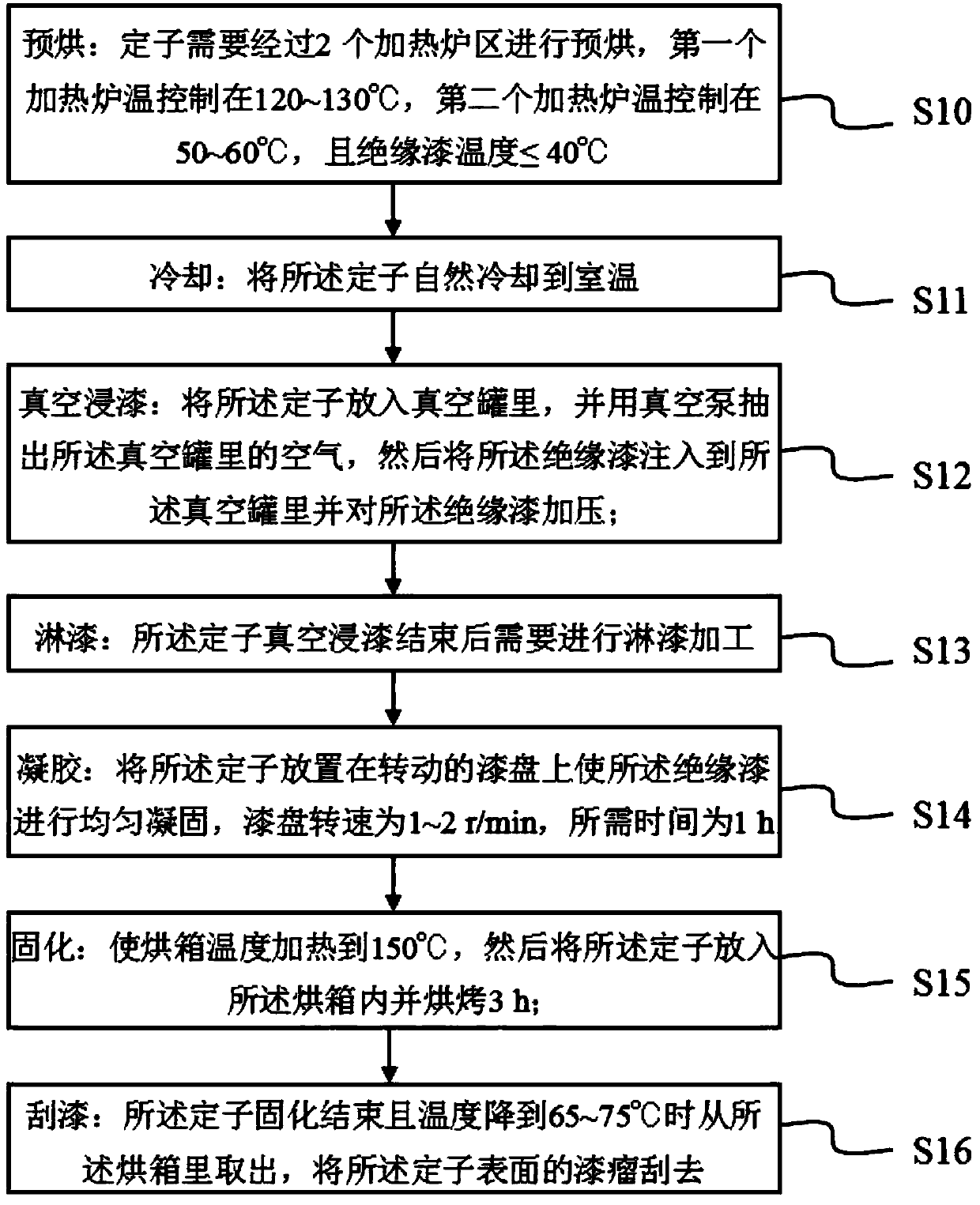

[0018] figure 1 It is a flow chart of the motor stator dipping process according to the embodiment of the present invention. Such as figure 1 As shown, the motor stator dipping process provided by the invention comprises the following steps:

[0019] In step S10: pre-baking, the stator needs to pass through two heating furnace zones for pre-baking, the temperature of the first heating furnace is controlled at 120-130°C, the temperature of the second heating furnace is controlled at 50-60°C, and the temperature ≤40°C, the water content of the stator is completely dried by heating at high temperature.

[0020] In step S11: cooling, the stator is pre-baked to allow it to cool naturally to room temperature to prepare for vacuum dipping.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com