Four-core square cable

A cable and square technology, applied in the field of four-core square cable, can solve problems such as cable short circuit, shortened cable life, twist and deformation, etc., to reduce external force damage and reduce electromagnetic interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

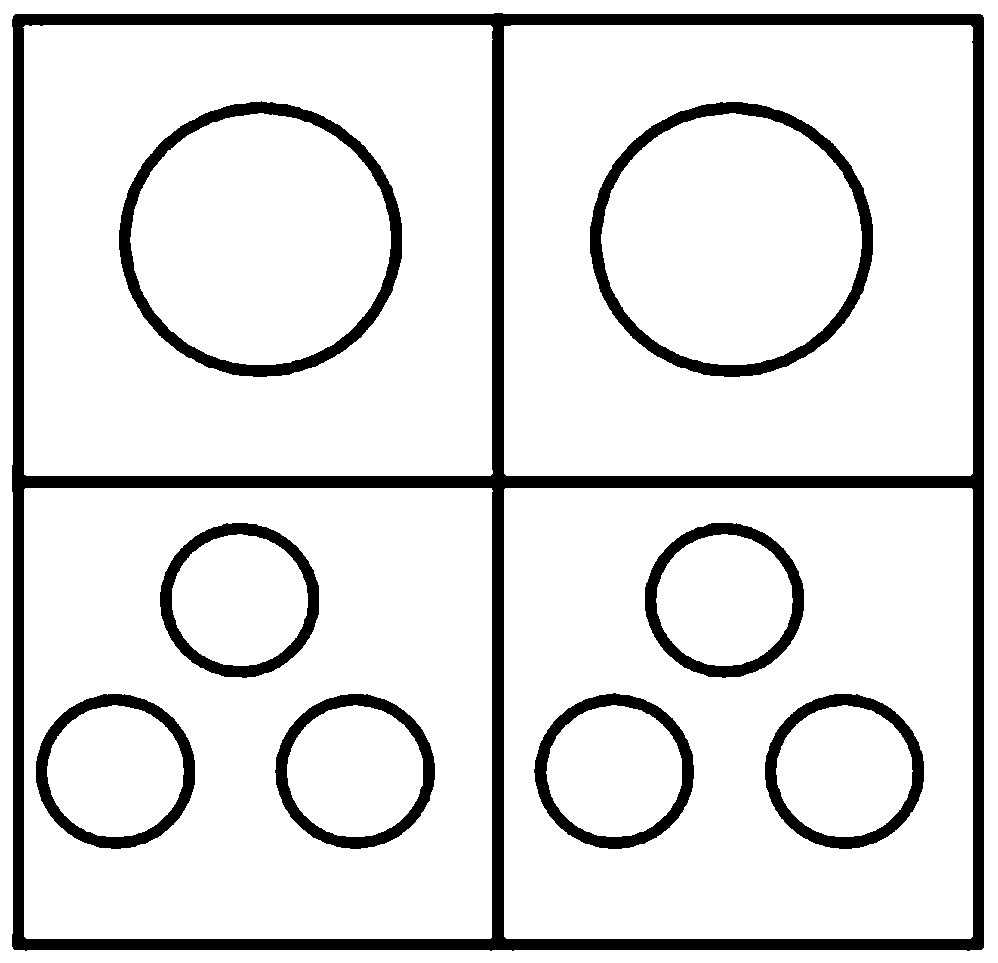

[0013] The structure of the present invention is as figure 1 As shown, the cable has a square structure, including a square outer sheath and four square cores twisted inside the outer sheath. The cable cores include a square insulating layer and several cores in the insulating layer.

[0014] As a further improvement, the number of said wire cores is one to three.

[0015] The wire core and the cable core of the present invention are both dragged directly, which saves filling materials and wrapping tapes, reduces the material waste of twisting to increase the length, and reduces the weight; and there is no entanglement between the wire core and the cable core, and the cables can be identified Easy to use and maintain. The phase wire core responsible for power transmission is located in the innermost layer, which can not only play a role similar to steel wire armor, but al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com