Method for aging test of plastic packaging bags

An inspection method and packaging bag technology, applied in the field of plastic film production, can solve problems affecting production efficiency, cost, and time, and achieve intuitive and reliable results, avoid uneven heating, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

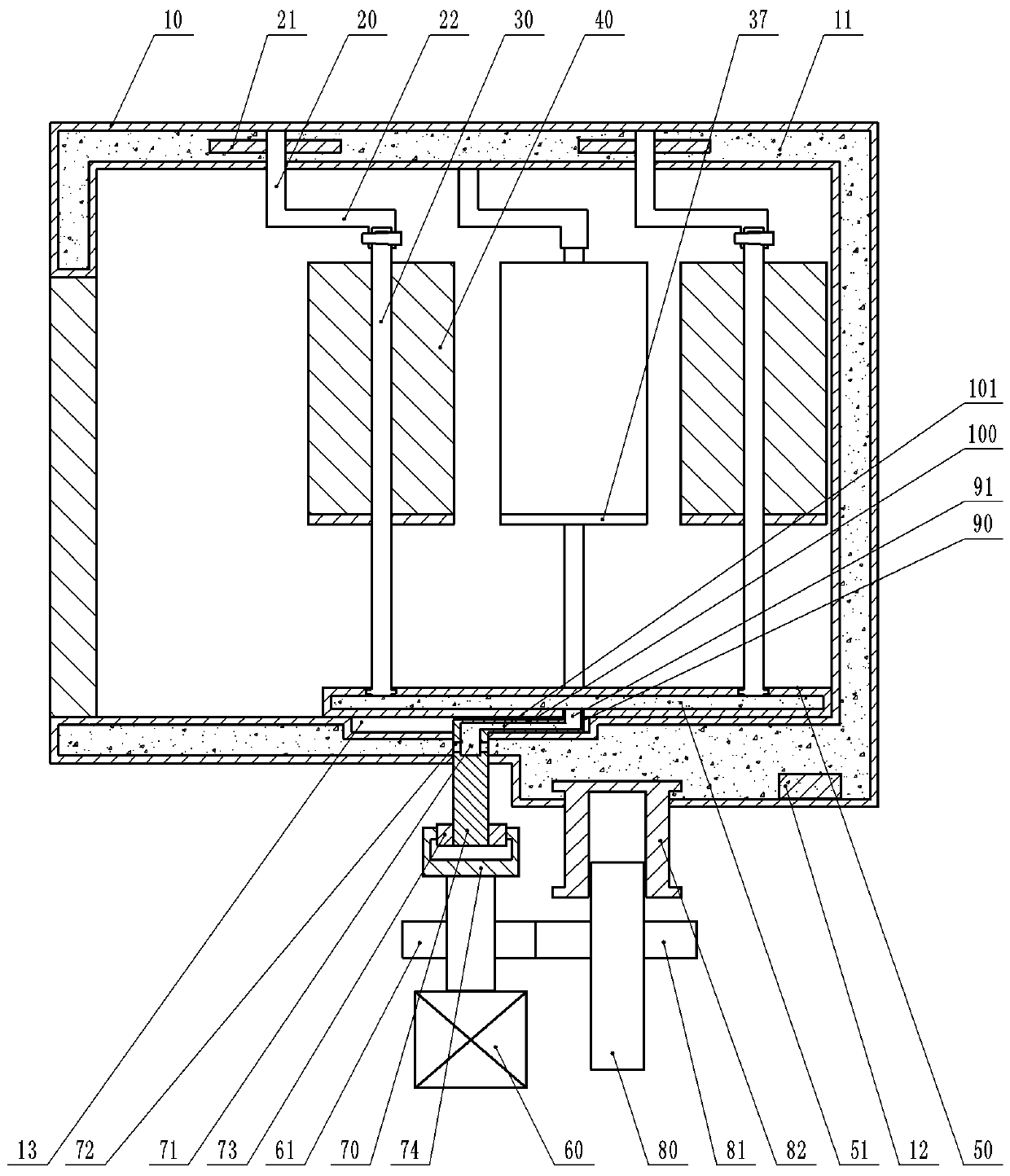

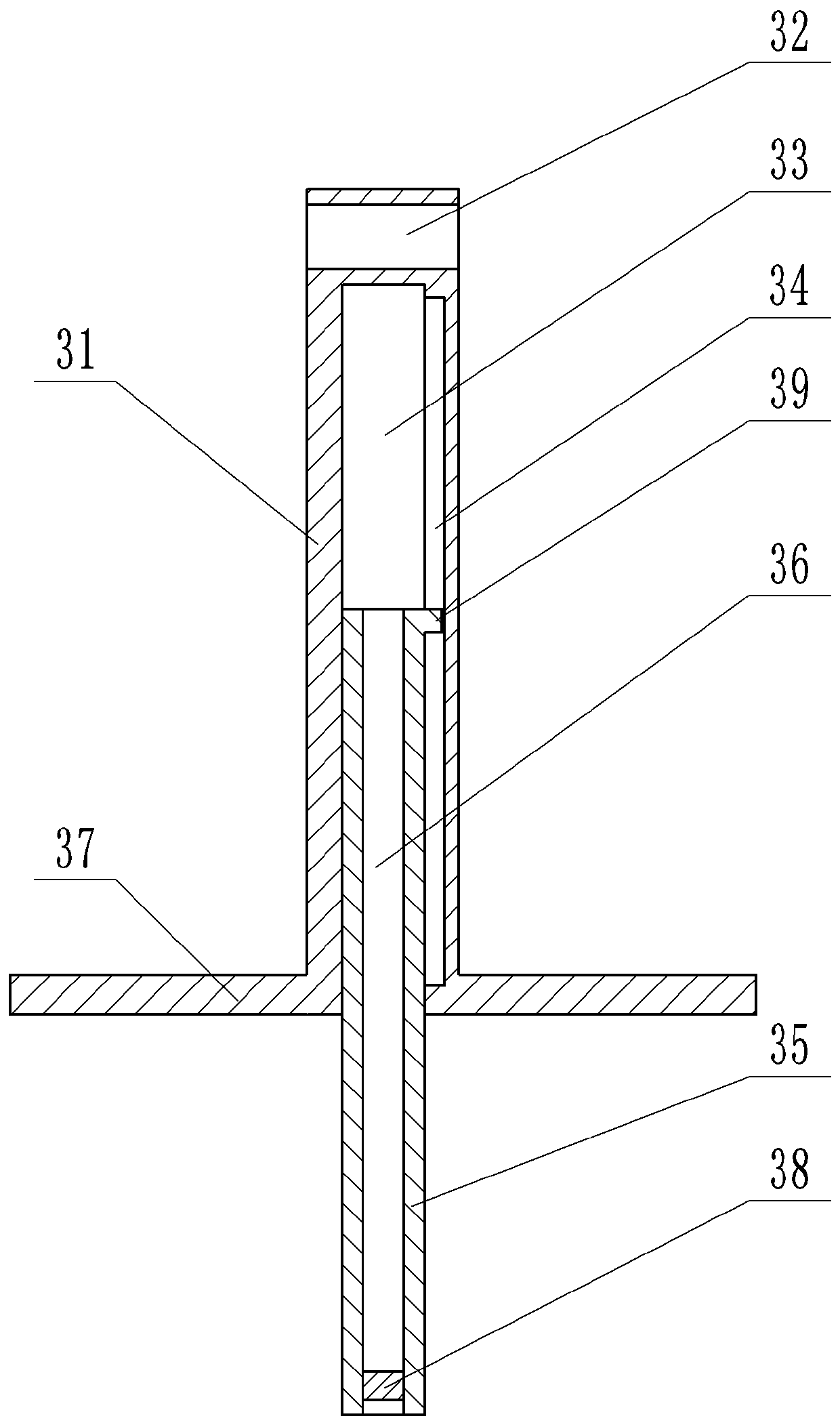

[0023] Instructions attached Figures 1 to 2The reference signs in include: heating chamber 10, oil chamber 11, heating wire 12, groove 13, vertical rod 20, stirring blade 21, cross rod 22, telescopic rod 30, outer rod 31, fixing hole 32, blind hole 33 , chute 34, inner rod 35, through groove 36, support plate 37, pressure valve 38, protrusion 39, composite film 40, turntable 50, cavity 51, motor 60, first gear 61, rotating rod 70, cavity 71, through hole 72, one-way bearing 73, turret 74, rotating shaft 80, second gear 81, plunger 82, vertical column 90, cavity 91, horizontal bar 100, channel 101.

[0024] The aging test method for plastic packaging bags includes the following steps:

[0025] (1) Material preparation: plastic packaging film 40 completed by winding and compounding;

[0026] (2) Ripening treatment: the rolled plastic packaging film 40 is placed in a rip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com