Cross-flow fan and air conditioner

A technology of cross-flow blades and blades, which is applied in the field of cross-flow blades, and can solve problems such as large injection mold volume, large impact at the same frequency of the volute tongue, and unnatural air-conditioning sound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

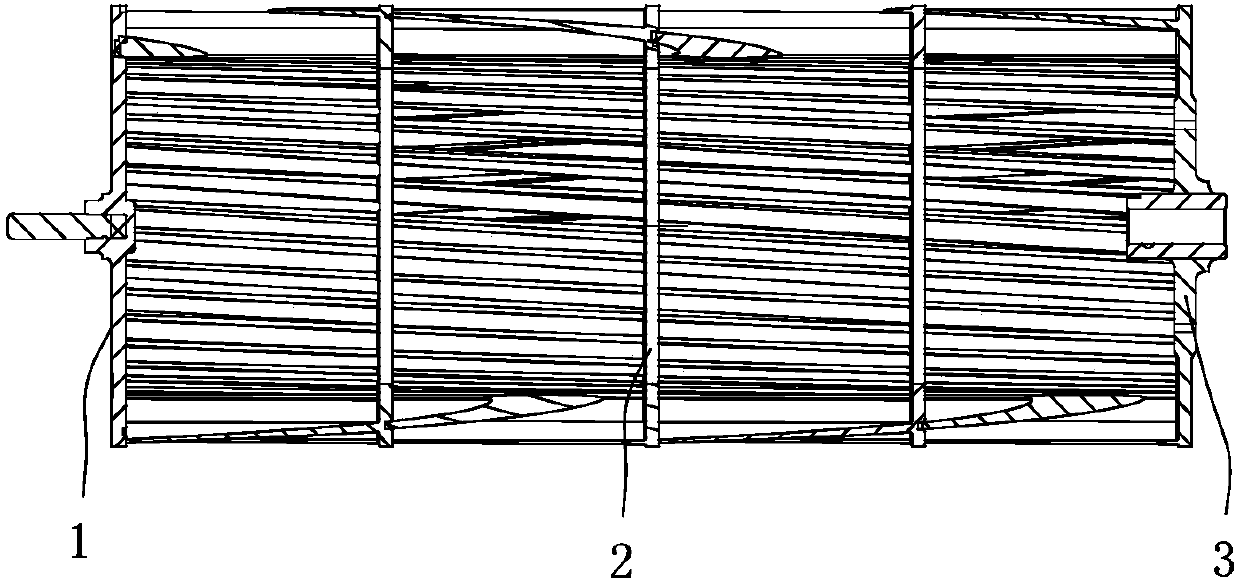

[0024] Such as Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 with Figure 11 The shown cross-flow vane includes a steel shaft end wheel 4 , multiple middle wind wheels 5 and a rubber end impeller 6 .

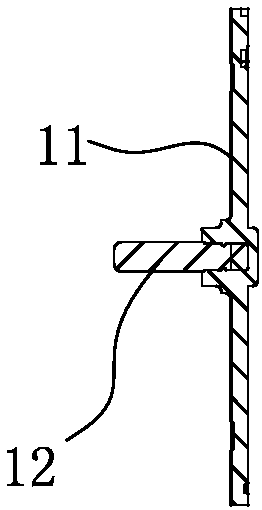

[0025] The steel shaft end wheel 4 includes a steel shaft disc 41 and a metal steel shaft 42, the steel shaft disc 41 is provided with a welding groove 43, the metal steel shaft 42 is inlaid in the middle of the steel shaft disc 41, and the metal steel shaft 42 is used to connect the air conditioner. bearings in the track.

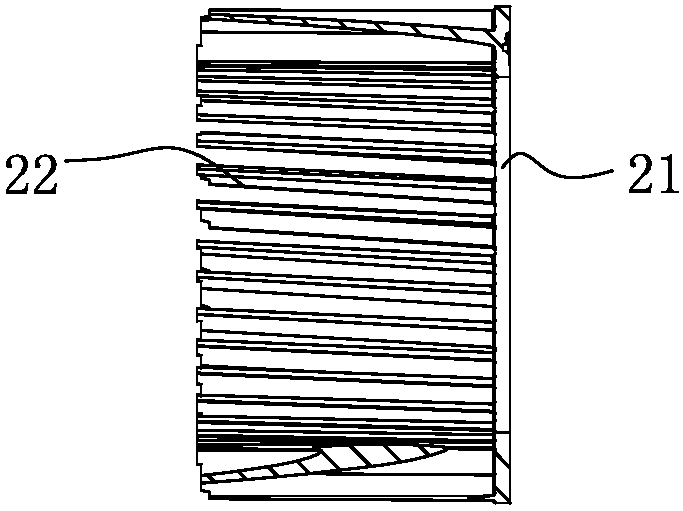

[0026] The middle wind wheel 5 comprises a middle plate 51 and a plurality of blades 52 connected thereto, the blades 52 are 31-39 pieces, the blade 52 rear end is integrally injection molded with the middle plate 51 front ends, and the middle part of each middle plate 51 is provided with There is a through hole 54, and the inner end of the middle plate 51 is provided with a circular groove 53, and the circular groove 53 is ste...

Embodiment 2

[0040] An air conditioner, which adopts the cross-flow fan blade of the above-mentioned embodiment 1, reduces the vibration of the cross-flow fan blade during operation, can reduce the noise and vibration of the whole machine, the noise is low, and the sound of the air outlet of the air conditioner is more natural and comfortable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com