Roadway U-shaped steel sleeving shed supporting structure

A technology of supporting structure and section steel, applied in tunnels, tunnel linings, shaft linings, etc., can solve the problems of increasing roadway maintenance costs, inability to act uniformly, accelerating roadway damage, etc., to reduce roadway maintenance costs, improve stability and support. The effect of protective strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

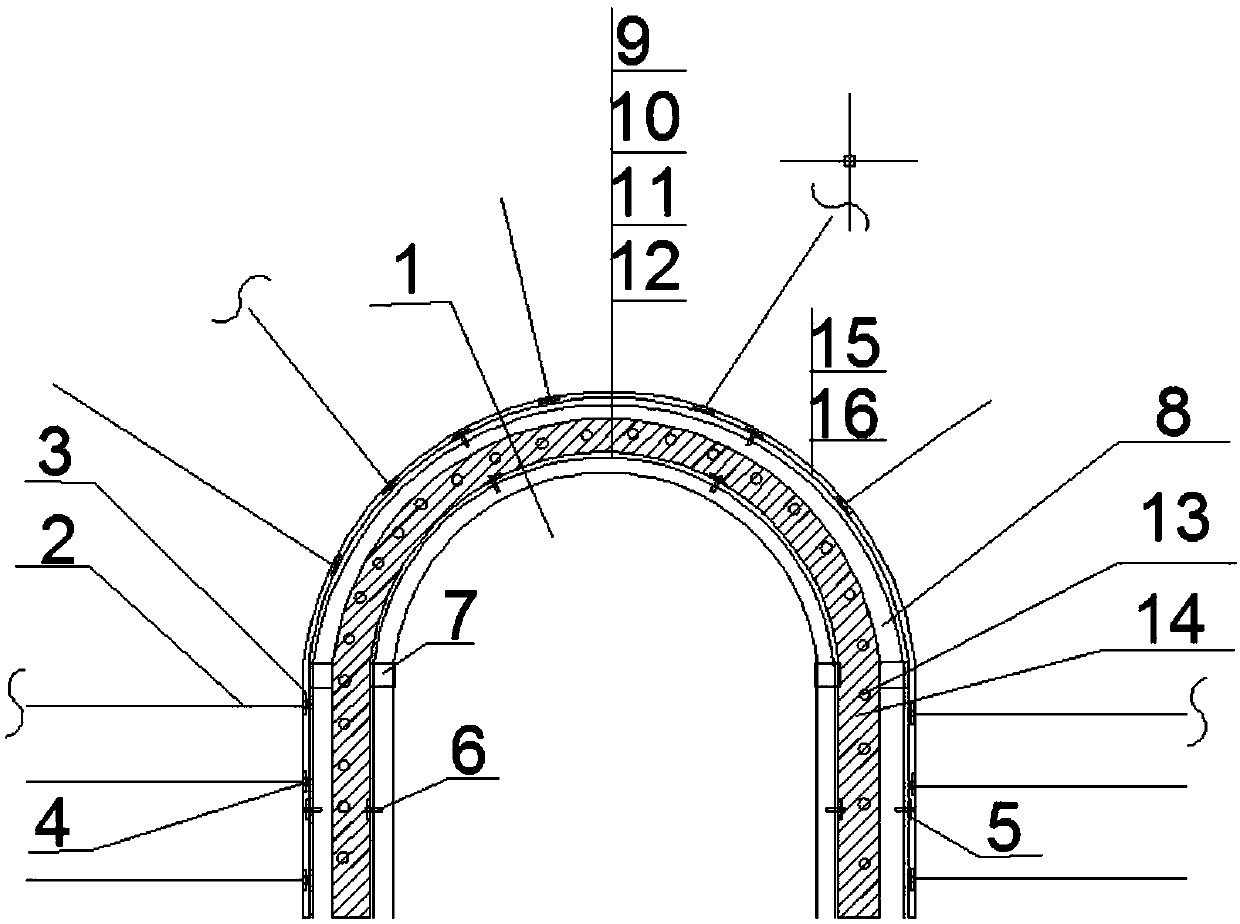

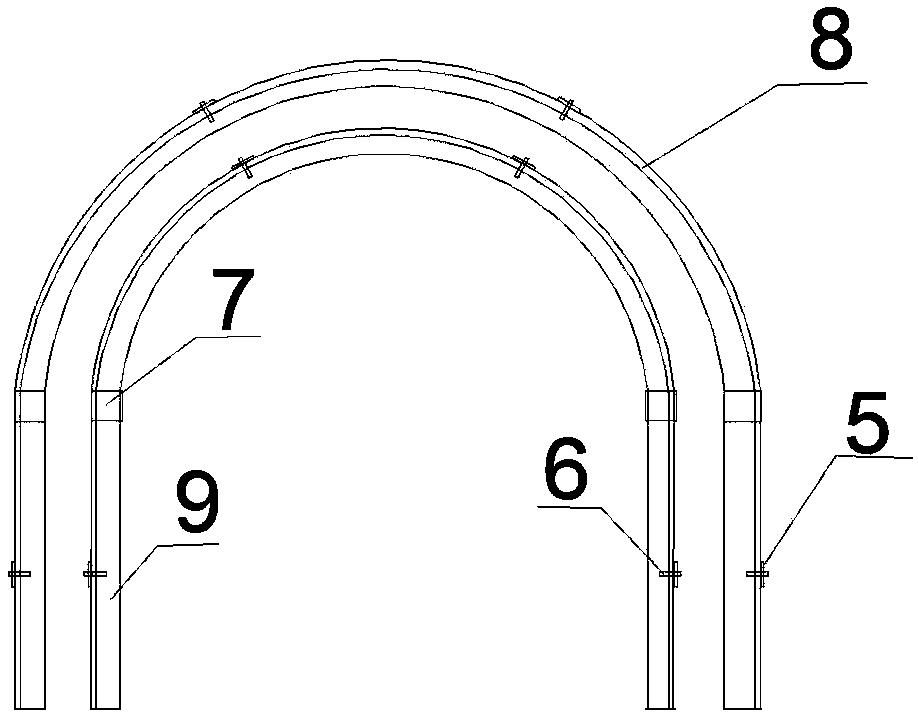

[0011] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0012] The present invention provides a roadway U-shaped steel shed support structure, including a metal mesh 15 hung on the surrounding rock surface of the roadway 1, and a steel bar ladder 16 arranged in a right-angle crossing manner, and the steel bar ladder 16 is arranged on the inner side of the metal mesh 15 , and the metal mesh 15 and the steel bar ladder 16 are fixed on the surrounding rock surface of the roadway 1 through the anchor cable 2, specifically: the roof of the roadway 1 and the surrounding rock are provided with anchor cable holes, and one end of the anchor cable 2 is fixed in the anchor cable hole, The other end is clamped and fixed on the inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com