Coronary plug mounting tool

A technology for installing tools and crowns, which is applied in the direction of wellbore/well components, earthwork drilling and production, etc., to achieve the effect of simple and reliable operation, ensuring reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

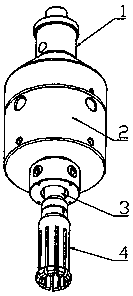

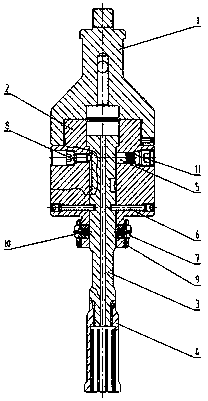

[0059] Embodiment one, such as Figure 1 to Figure 4 Shown:

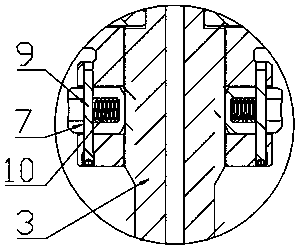

[0060] A crown plug installation tool, including a body 2, an upper joint 1, a mandrel 3, a pressure spring, a lock block 7 and a lock block limiter;

[0061] The body 2 is a cylindrical structure as a whole, and a stepped hole is provided through the interior of the body 2 along the axial direction; the body 2 is top, middle and bottom from top to bottom, wherein the top and the upper joint 1 Detachable fixed connection; the outer diameter of the middle part is greater than the inner diameter of the drive cylinder of the crown plug and is used to push the upper end surface of the drive cylinder of the crown plug; the outer diameter of the bottom is smaller than the outer diameter of the middle part and can be inserted into the drive cylinder of the crown plug Inside, and the outer surface of the bottom is radially provided with lock block installation holes, the lock block installation holes are at least two evenl...

Embodiment 2

[0092] Embodiment two, not shown in the figure:

[0093] The difference between this embodiment and the foregoing embodiment is that:

[0094] There is a block at the outer end of the mounting hole of the lock block, and there is a hole in the middle of the block;

[0095] The locking block is a bar-shaped structure in which the outer surface is slidingly fitted with the inner surface of the piercing hole;

[0096]The stopper of the lock block is a piston rod, and the end face of the piston rod is vertically fixedly connected with the end of the lock block away from the hole, and the side of the piston rod and the inner surface of the lock block installation hole are slidingly fitted. connected;

[0097] The compression spring is sleeved on the locking block and its two ends abut between the baffle plate and the locking block limiter.

[0098] This embodiment also enables the outer end of the lock block to extend or retract under the drive of the mandrel 3 . However, this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com