Double-layer spunlace non-woven fabric for sanitary napkin

A technology for spunlace non-woven fabrics and sanitary napkins, which is applied in the field of sanitary products, can solve the problems of large re-infiltration, consumption of natural resources, strong feeling of stuffiness and wetness of consumers, etc., so as to reduce the usage amount, reduce the feeling of stuffy and wetness, and increase comfort sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

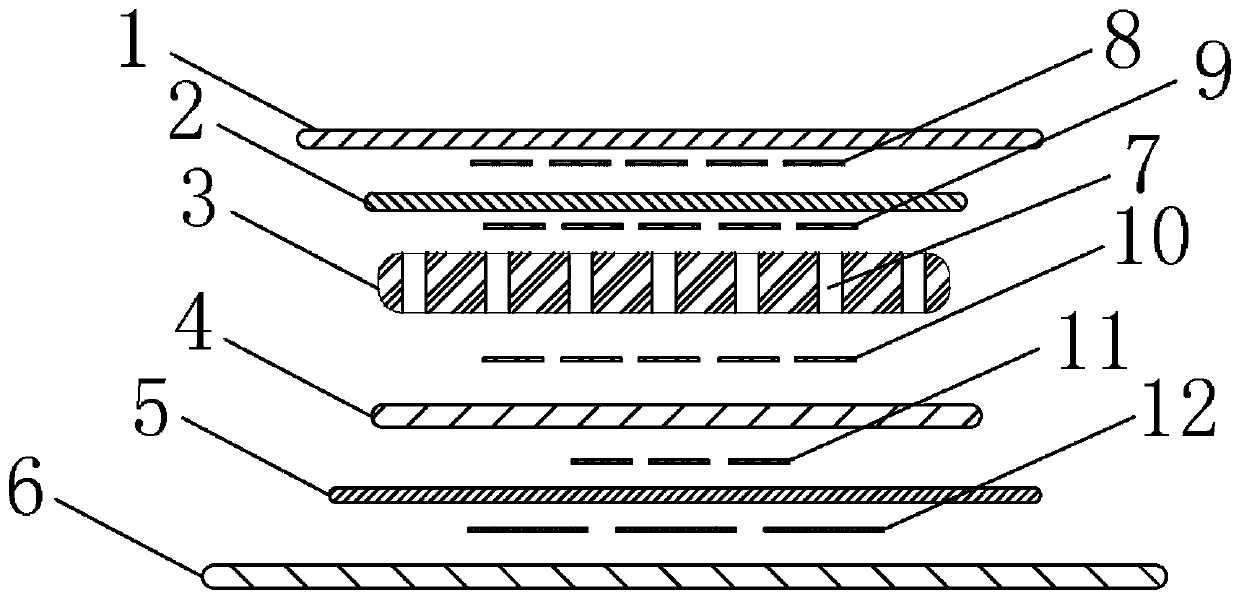

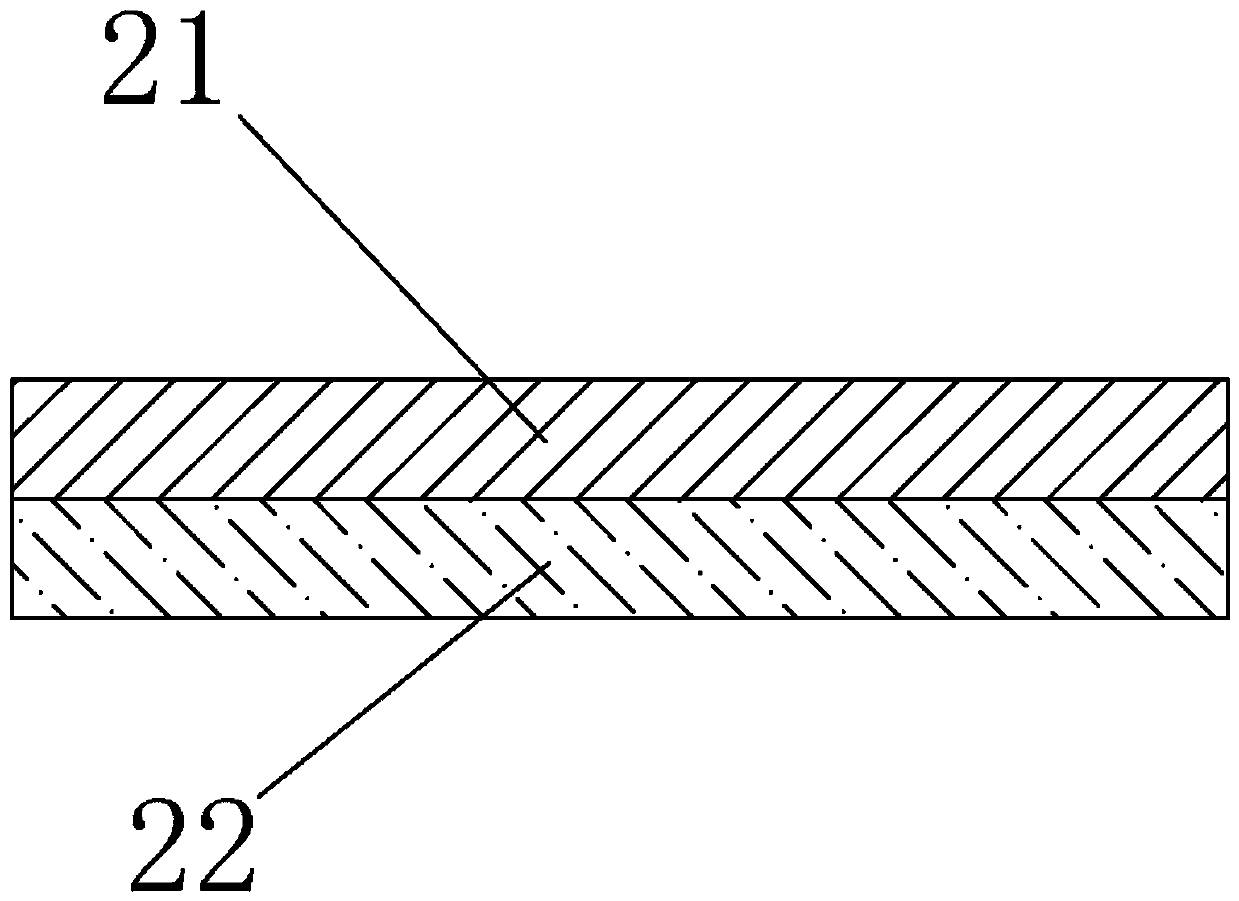

[0020] refer to figure 1 , figure 2 , a double-layer spunlace non-woven fabric for sanitary napkins, the sanitary napkin includes a fabric layer 1, a flow guide layer 2, an absorption layer 3, a protective bottom film 4, and a self-adhesive release paper 5 sequentially stacked from top to bottom and the envelope 6, a structural glue layer is arranged between the above-mentioned adjacent layers, the fabric layer 1 is composed of a double-layer structure, the upper layer is a cotton fiber layer 21, and the lower layer is a mixed fiber layer 22, the gram of the fabric layer The weight is 30-40 grams per square meter. The fabric layer 1 of the present invention, that is, the double-layer spunlace non-woven fabric, adopts a double-layer combination method in a pioneering manner, and adopts a two-layer structure, that is, the upper layer uses cotton fibers, and the lower layer uses mixed fibers. The fiber structure is formed in one pass by the hydroentanglement process. It not on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com