A method for preparing tungsten-molybdenum-copper composite material by high-current resistance sintering

A composite material and high-current technology, which is applied in the direction of improving process efficiency and energy efficiency, can solve problems such as high sintering temperature, long sintering time, and complicated process, and achieve low sintering temperature, short sintering time, and promote crystal lattice Diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~20

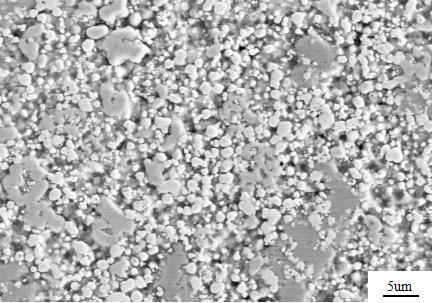

[0029] 1. Add copper powder with a particle size of 20~30μm, tungsten powder and molybdenum powder with a particle size of 2~3μm into the high-energy planetary ball mill for ball milling according to the mass ratio listed in the table, and add a little alcohol into the ball mill tank at the same time To prevent the powder from being oxidized during the ball milling process.

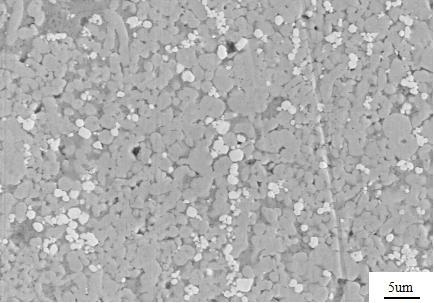

[0030] 2. Put the tungsten-molybdenum-copper powder mixed by the ball mill into the mold and press it into a green body with a cylindrical structure, and the relative density of the green body is kept at 68%~80%.

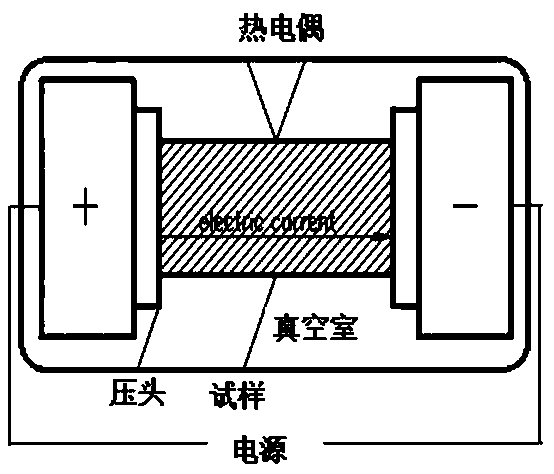

[0031] 3. Place the green body in the heating equipment, in an electric field with an output voltage of 3~10V, an output current of 4000~12000A, and a vacuum degree of 10 -3 Under the condition of Pa, the green body is directly energized for rapid heating, so that the green body is heated to 200°C and then kept for 1~5min, and then the temperature is continued to rise to 700~1000°C at a heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com