A sequencing batch anaerobic dry fermentation method and its device with enhanced warming function

A fermentation method and a technology of a fermentation device, which are applied in the field of leachate reflux and temperature increase in a biogas project of sequenced batch type anaerobic dry fermentation, can solve problems affecting biogas production efficiency, etc., and achieve improved temperature increase efficiency and heat preservation effect, improved efficiency and stability The effect of improving the efficiency of biogas production by anaerobic fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

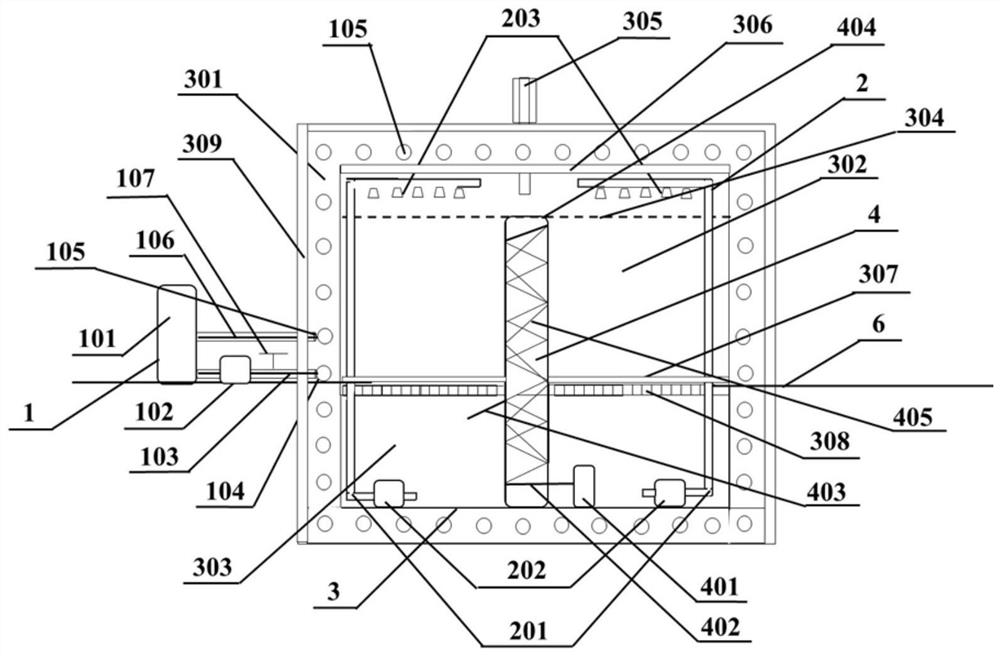

[0024] A sequencing batch anaerobic dry fermentation device with enhanced warming function:

[0025] The solid content rate of the material is 30%, the material ratio (solid content rate) straw: livestock and poultry manure is 6:4, and the inoculum concentration is 35% of the effective volume of the anaerobic dry fermentation reactor (3). Fermentation reactor (3), the material is heated to 38°C by the external source water circulation heating system (1); the leachate backflow spraying heating system (2) is 8 times per day according to the spraying frequency, and the spraying amount is 1L / kg, the material uses the external source heat supply temperature to spray part of the hot leachate onto the surface of the material, and maintains a constant temperature of the material in the spray-infiltration area through percolation; part of the hot leachate enters the anaerobic dry fermentation reactor The central thermal leachate circulation warming system (4) in (3) increases the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com