A system and method for recovering refined methylcyclopentane and its application

A technology of methylcyclopentane and reflux ratio, which is applied in chemical instruments and methods, purification/separation of hydrocarbons, sustainable manufacturing/processing, etc., and can solve problems such as failing to meet high purity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

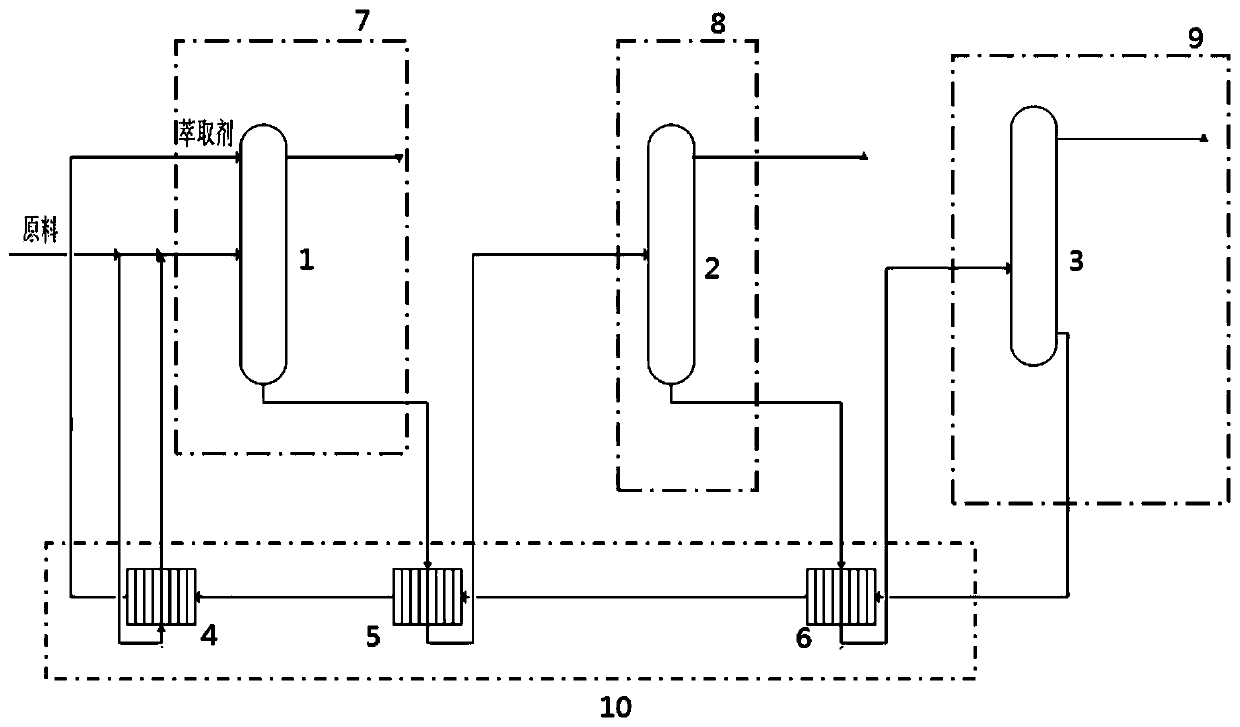

[0052] A system for recovering refined methylcyclopentane, such as figure 1 As shown, it includes a delightening unit 7, a purification unit 8 and a solvent recovery unit 9 connected in sequence, and also includes a heat exchange unit 10;

[0053] Wherein, light removal unit 7 is extractive distillation column I1; purification unit 8 is extractive distillation column II2; heat exchange unit 10 includes first plate heat exchanger 4, second plate heat exchanger 5 and third plate heat exchanger independently Heat exchanger 6; the solvent recovery unit is a rectifying tower 3; the raw material input pipeline is connected to the raw material inlet on the extractive distillation tower I1 after passing through the first plate heat exchanger 4; the bottom of the extractive distillation tower I1 is provided There is a first pipeline, which is connected to the extractive distillation tower II2 after passing through the second plate heat exchanger 5; the bottom of the extractive distilla...

Embodiment 2

[0060] The system is the same as in Embodiment 1, and the method is similar, except that:

[0061] The composition of the extractant is: the content of DMF is 80wt%, and the content of DES is 20wt%. DES is a deep eutectic solvent obtained by stirring hydrogen bond acceptors and hydrogen bond donors with a molar ratio of 1:5 at 90°C until transparent ; The hydrogen bond acceptor is: choline chloride, and the hydrogen bond donor is levulinic acid. The operating pressure of extractive distillation column I1 is 1.4MPa, the temperature at the top of the tower is 27.5°C, the temperature of the tower bottom is 105°C, and the reflux ratio is 0.3; The ratio is 8; the operating pressure of rectification tower 3 is 1.5MPa, the tower top temperature is 95°C, the tower bottom temperature is 200°C, and the reflux ratio is 1.5;

[0062] The purity of the methylcyclohexane product extracted from the top of the extractive distillation column II2 is 99.97w%, and the recovery rate is 99.05%.

Embodiment 3

[0064] The system is the same as in Embodiment 1, and the method is similar, except that:

[0065]The composition of the extractant is as follows: the content of sulfolane is 45 wt %; the content of DES is 30 wt %; and the content of ethylene glycol is 25 wt %. DES is a deep eutectic solvent obtained by stirring hydrogen bond acceptors and hydrogen bond donors at a molar ratio of 1:10 until transparent at 100°C; the hydrogen bond acceptor is betaine, and the hydrogen bond donor is urea. The operating pressure of extractive distillation column I1 is 1.4MPa, the temperature at the top of the column is 28°C, the temperature at the bottom of the column is 110°C, and the reflux ratio is 0.5; , the reflux ratio is 10; the operating pressure of the rectification tower is 1.5MPa, the tower top temperature is 95°C, the tower bottom temperature is 210°C, and the reflux ratio is 1.

[0066] The purity of the methylcyclohexane product extracted from the top of the extractive distillation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com