Composite mirror blank material for ceramic-based space mirror

A mirror, ceramic-based technology, applied in the field of preparation of low-expansion glass, can solve the problems of inability to obtain the required reflectivity, limited application and development, high brittleness of glass materials, etc., and achieves polishing requirements, short polishing time, and complete surface. Dense, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in conjunction with accompanying drawing and specific embodiment:

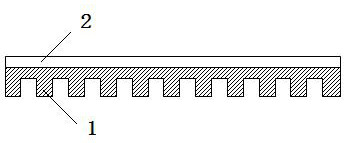

[0019] Such as figure 1 As shown, a composite mirror blank material for a ceramic-based space mirror, the composite mirror blank material includes an alumina ceramic 1 and a glass glaze 2; the alumina ceramic is Al 2 o 3 ≥99.0% corundum ceramics; the glass glaze 2 is welded to the surface of the alumina ceramic 1; the glass glaze 2 is borosilicate glass; the expansion coefficient of the borosilicate glass is lower than that of alumina ceramics, The difference between the expansion coefficients of the alumina ceramic ceramic and the borosilicate glass in the range of 20-400°C Δα≤±0.5×10 -6 / K.

[0020] The raw material composition and weight ratio of the borosilicate glass are: SiO 2 : 72.0~75.0%, Al 2 o 3 : 1.0~2.5%, B 2 o 3 : 6.0~8.0%, R 2 O: 10.0~12.0%, RO: 6.0~8.0%; said R 2 O includes K 2 O, Na 2 O, the RO includes CaO, ZnO, MgO, where K 2 O≥2.0%, Na ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com