Box collecting machine used after detection of electronic printed products and inspection machine for small-piece printed products

A printed matter and post-inspection technology, which is applied in the field of small-sheet printed matter inspection machines, can solve the problems of unsuitable electronic printed matter, easy damage, easy scratches, etc., and achieve the effects of shortening the delivery cycle, high degree of automation, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

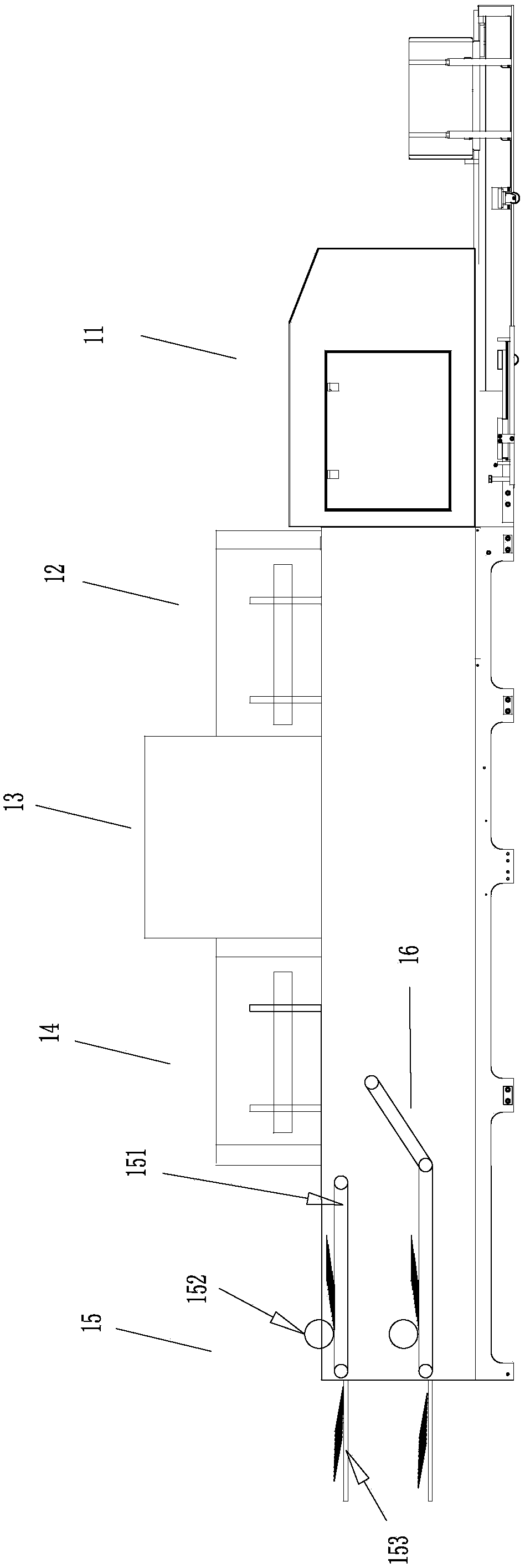

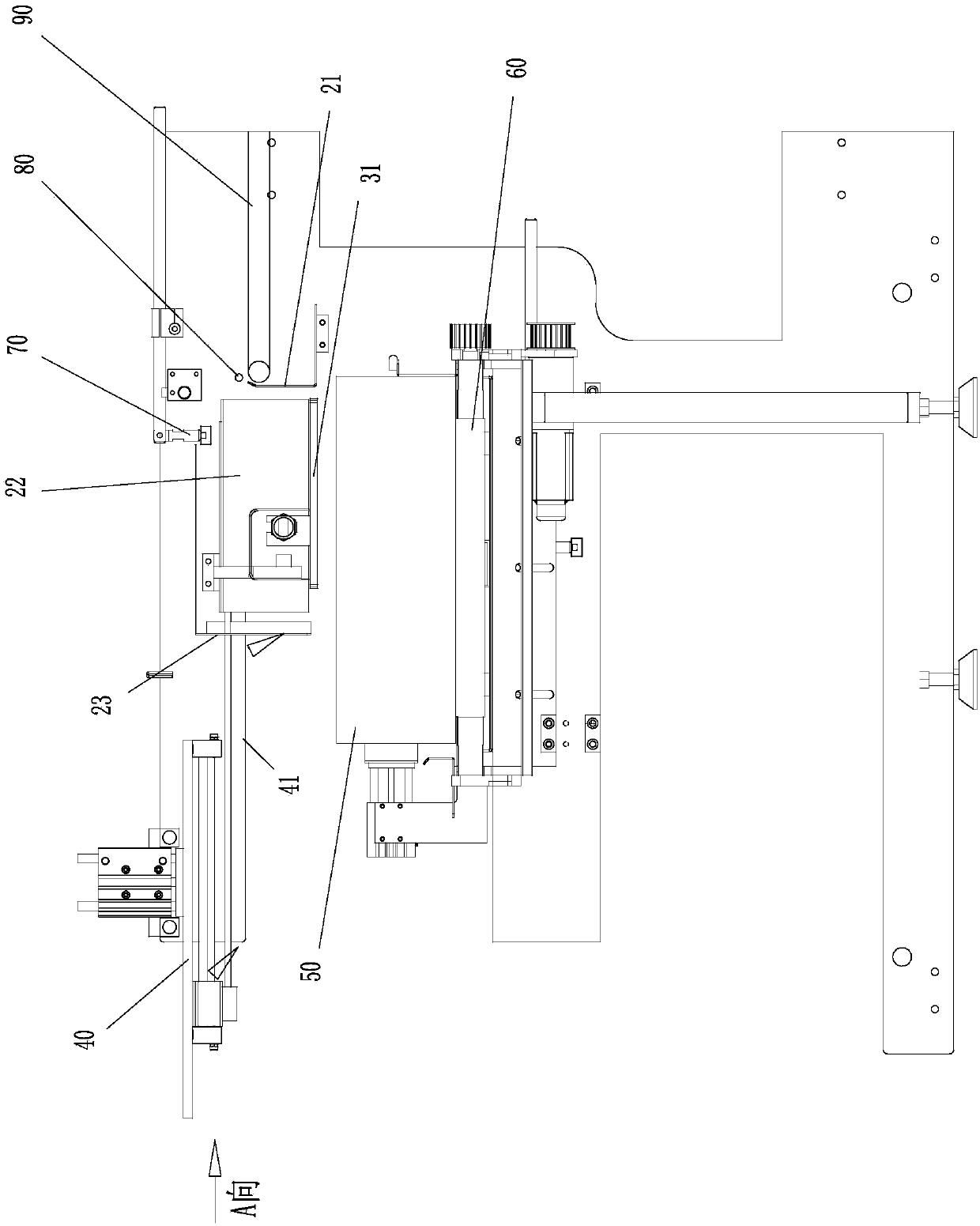

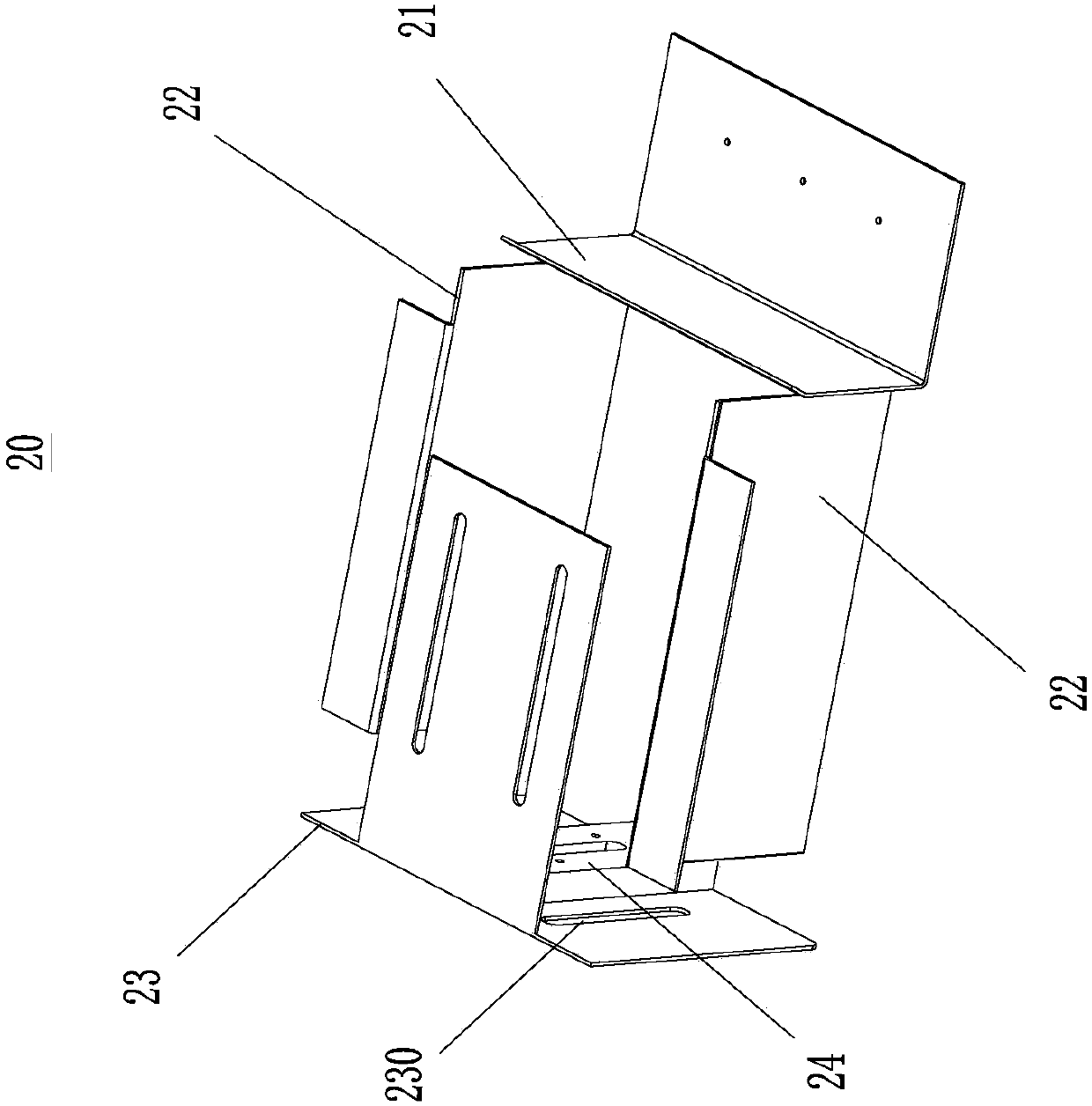

[0015] like Figure 2 to Figure 6 As shown, the box receiving machine after the electronic printed matter inspection of the present invention includes a baffle mechanism 20 corresponding to the output port (finished product output port or waste product output port) of the waste discharge machine 90 of the traditional small-sheet printed matter inspection machine, and the baffle mechanism 20 A rectangular frame is formed, an upper air blowing mechanism 70 for blowing downward is installed above the upper opening of the rectangular frame, a pallet delivery mechanism 30 is installed under the lower opening of the rectangular frame, and a turnover mechanism 30 is arranged below the pallet delivery mechanism 30. The box conveying mechanism 60 is placed with a turnover box 50 on the turnover box conveying mechanism 60, a photoelectric counter 80 is installed at the output port of the waste discharge machine 90, and a pin delivery mechanism 40 is installed beside the baffle mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com