Solar hydrogen permeation membrane reaction device and use method thereof

A technology of a reaction device and a hydrogen permeable membrane is applied in the chemical method of reacting liquid and gas medium, the reaction of liquid and gas in thin film, chemical instruments and methods, etc. The problems of complex process and high consumption of fossil energy can reduce the loss of thermal radiation energy, improve the conversion rate of reactants, and save the area of the mirror field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

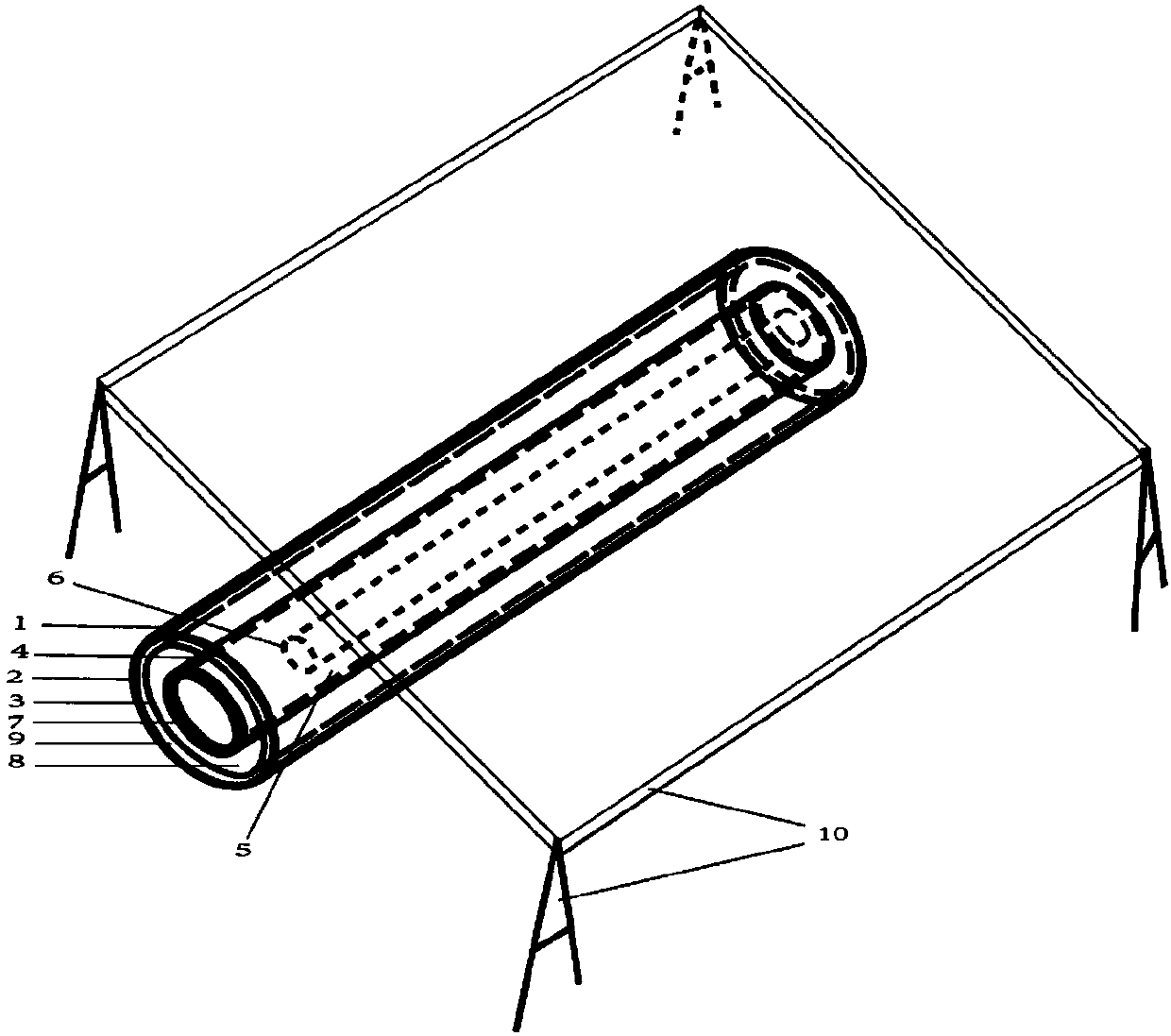

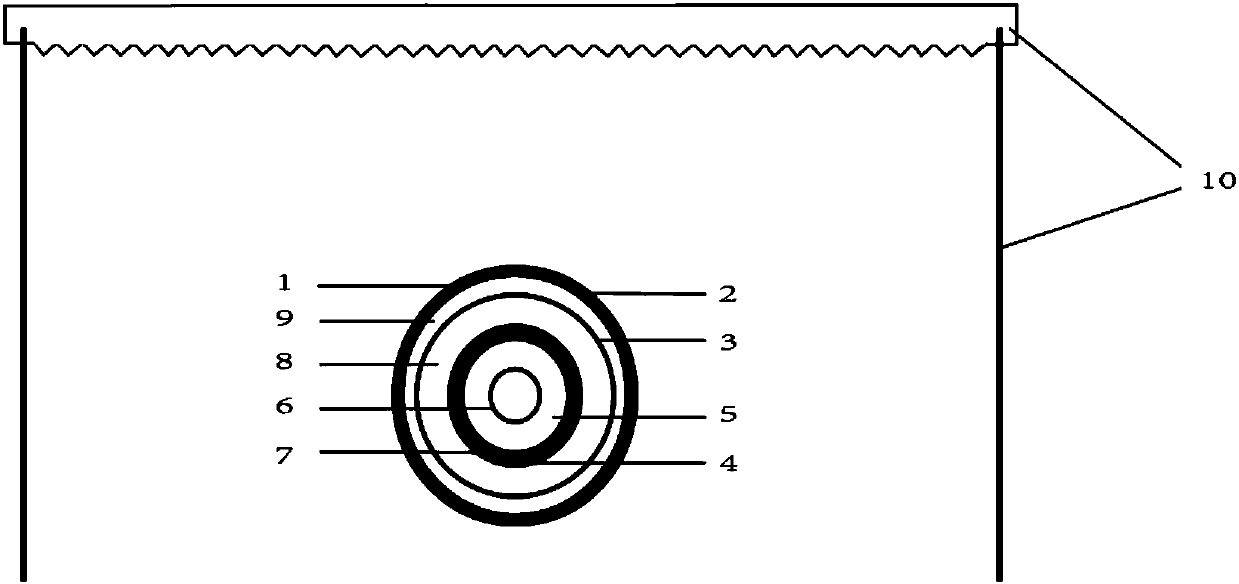

[0041] This example is the preparation of hydrogen production by steam reforming of methane.

[0042] The solar heat collecting tube is installed on the focal line of the solar concentrating device. Under the same conversion rate requirements, compared with the traditional high-temperature steam reforming of methane to produce hydrogen, the thermochemical reaction temperature in this embodiment can be reduced to 300°C-400°C. In this embodiment, the solar concentrating device adopts a linear Fresnel type solar concentrating device, the concentrating ratio ranges from 30 to 100, and the temperature of the solar heat collecting tube on the focal line can reach 400°C. According to the coupling relationship between the temperature required for the methane steam reforming reaction and the heat collection temperature of the solar heat collector, solar energy can be used as the heat source for the methane steam reforming reaction. The thermochemical reaction channel is filled with Ru...

Embodiment 2

[0050] This embodiment is the hydrogen production reaction of ammonia decomposition, which is also an endothermic reaction, and the reaction equation is as follows:

[0051]

[0052] The energy change ΔH of the chemical reaction in this reaction θ 298 = 92.4 kJ / mol. In this embodiment, ammonia gas is used as the raw material gas, and the reaction device and reaction process are the same as in Embodiment 1. The temperature of the solar heat collecting tube is controlled to stabilize at 400° C. by adjusting the concentration ratio of the linear Fresnel type solar concentrating device. The thermochemical reaction channel is filled with a catalyst La 1-x Sr x NiO 3 . Other process conditions are with reference to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com