Wet smoke plume eliminating system

A technology for eliminating system and wet smoke, applied in the direction of using liquid separating agent, combined device, dispersing particle separation, etc., can solve the problem of not completely eliminating wet plume of chimney, reduce temperature, ensure safe and stable operation, and resist corrosion. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

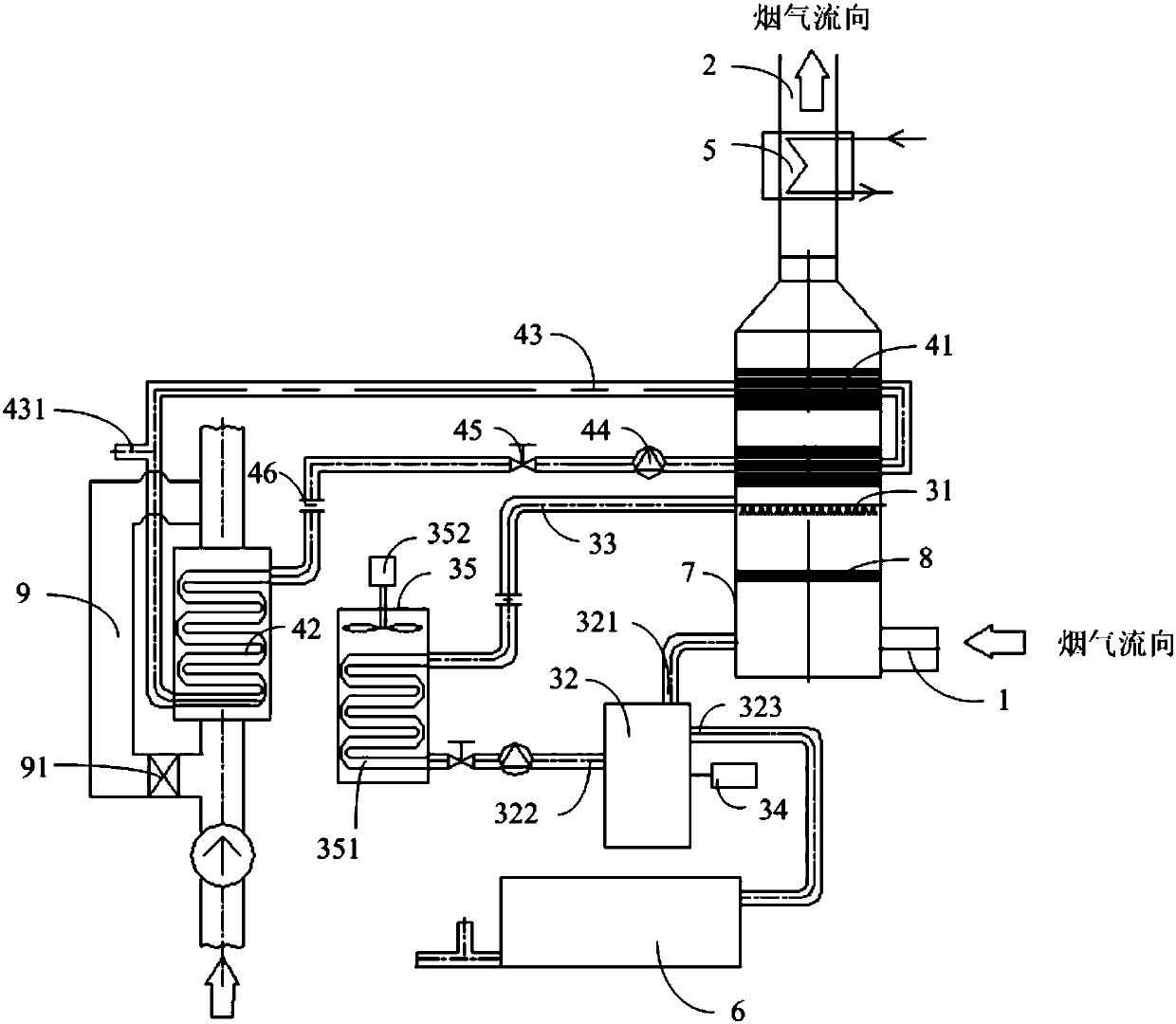

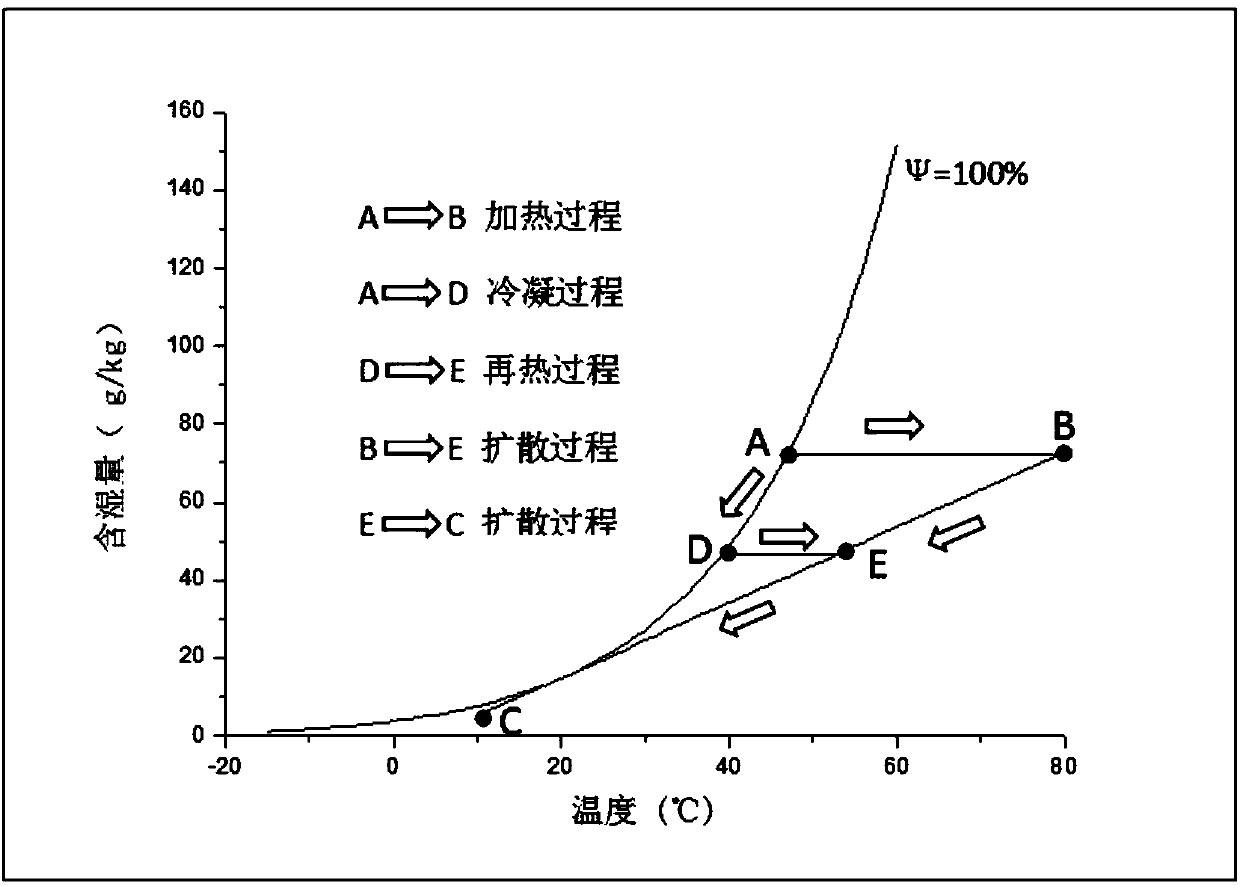

[0032] Please refer to figure 1 with figure 2 , figure 1 It is a structural schematic diagram of the wet plume elimination system provided by the embodiment of the present invention; figure 2 is the schematic diagram of wet plume elimination.

[0033] Such as figure 1 As shown, the embodiment of the present invention provides a wet plume elimination system, which includes a first cooling subsystem, a second cooling subsystem and a heater 5 sequentially arranged between the flue gas outlet of the desulfurization tower and the chimney. Wherein, the first cooling subsystem includes a first circulating water circuit 33, which is provided with a spray device 31 and a circulating water tank 32, and the second cooling subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com