A kind of watercress salad dressing and preparation method thereof

A salad dressing and watercress technology, applied in food ingredients as taste improver, food science, food preservation and other directions, can solve the problems of low fat content and limited use range, and achieve extended shelf life, easy operation, improved umami and overall flavor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

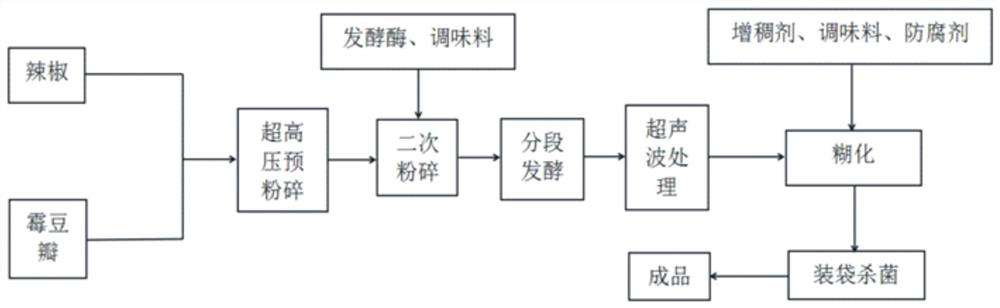

Method used

Image

Examples

Embodiment 1

[0031] A Bean Salad Dressing

[0032] (1) Preparation of moldy bean paste: cut the dried broad bean into two parts with a knife, soak in clean water for 24 hours, after the broad bean skin is soaked soft, remove and peel off the broad bean skin, wash it in running water, drain Dry, blanch in boiling water for 10-20 seconds, remove and drain, let the water vapor on the surface of broad bean flaps dry naturally, then put them into a fermentation tank, add 13% salt water to submerge broad bean flaps, and close the fermentation tank , After the broad bean is fermented to a soft texture inside and outside, the fermentation is completed, and the moldy bean is obtained.

[0033] (2) Processing of raw materials: Choose 72kg of fresh peppers without rot and deterioration as raw materials, wash and spread them on metal racks to air dry, and set aside; choose moldy Douban 24kg, rinse gently with clean water and retain more than 80% yellow mold, spread Air dry on a wire rack and set asid...

Embodiment 2

[0041] A Bean Salad Dressing

[0042] The preparation method is the same as that in Example 1, except that the watercress salad dressing is made of the following raw materials in proportion by weight: 20kg moldy watercress, 64kg pepper, 2kg salt and 0.1kg fermentation enzyme. In step (2), the ultra-high pressure pre-crushing pressure is selected as 200MPa; in step (5), the ultrasonic treatment temperature is 80°C, the output power is 600W, and the treatment time is 60min.

Embodiment 3

[0044] A Bean Salad Dressing

[0045] The preparation method is the same as that in Example 1, except that the watercress salad dressing is made of the following raw materials in proportion by weight: 28kg of moldy watercress, 80kg of pepper, 4kg of salt and 0.3kg of fermentation enzyme. In step (2), the ultra-high pressure pre-crushing pressure is selected as 400MPa; in step (5), the ultrasonic treatment temperature is 100°C, the output power is 1000W, and the treatment time is 30min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com