Tomato plug seedling raising substrate block and preparation method thereof

A technology for raising seedlings and substrate blocks in a plug tray, which is applied in the agricultural field, can solve problems such as rising labor costs, and achieve the effects of improving labor productivity, reducing early fertilization, and improving the breeding environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of above-mentioned tomato plug seedling cultivation substrate block is as follows:

[0029] First, according to the matrix components in the matrix block, the decomposed livestock and poultry manure, peat, vermiculite, and perlite are mixed according to the volume ratio of the matrix formula: 50%-70% of decomposed livestock and poultry manure, 10%-20% of peat, and 10% of vermiculite. %-20%, 10%-20% of perlite, mix and stir evenly, then add the adhesive of 25%-50% of the mass of the matrix, mix and stir evenly again; then put the matrix on a plate, press the hole, and carry out in a 70°C oven Dry for 2-3 hours to obtain the tomato plug seedling-raising substrate block, then perform manual and mechanical automatic plug sowing, and cover with the above-mentioned mixed substrate.

[0030] The livestock and poultry manure used in the formula components of the matrix block is completely fermented and decomposed, and the matrix block meets the requiremen...

Embodiment 1

[0034] The matrix block for cultivating tomato seedlings in the embodiment of the present invention is composed of 50%-70% of decomposed livestock and poultry manure, 10%-20% of peat, 10%-20% of vermiculite, and 10%-20% of perlite according to the mixing volume ratio. Mixing, adding 25%-50% of the mass of the matrix to form an adhesive.

[0035] The preparation method of the matrix block for tomato plug seedling cultivation, first, decomposes and ferments the fermentation raw material composed of pig manure biogas residue, stevia rebaudiana, and mushroom residue. The pig manure biogas residue used comes from a biogas power plant, and the biogas slurry of the biogas power plant is Pig manure biogas residue is obtained at the centrifugal dehydration place. The decomposing and fermentation treatment of livestock and poultry manure is to mix pig manure biogas residue with stevia and mushroom residue according to the weight ratio of 5:2:3 to form a material with a water content of ...

Embodiment 2

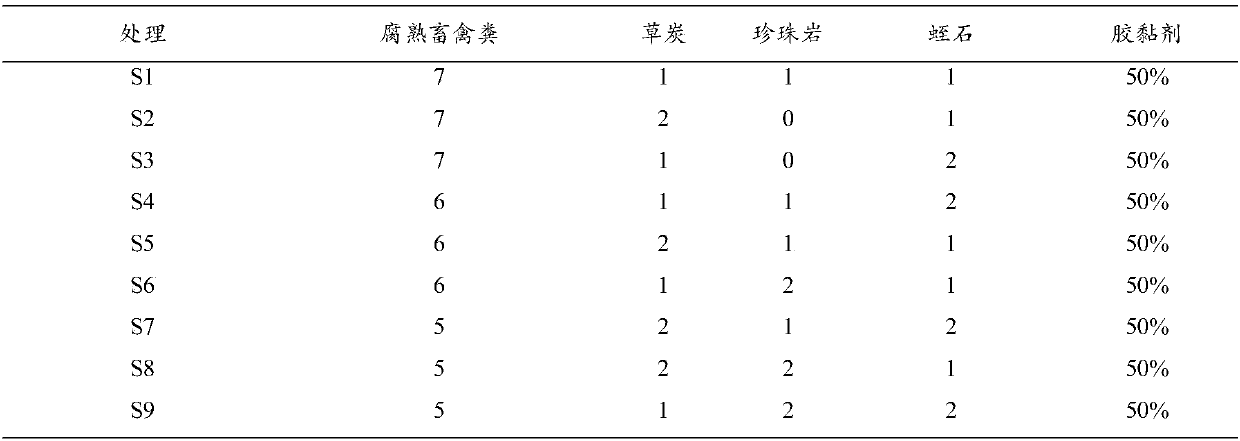

[0039] The tomato variety was chosen as Sufen No. 8. According to the comparison in the previous experiments, the adhesive with 50% matrix mass was better. The formulas of different matrix blocks are shown in Table 1. Control group (CK): Purchase ordinary vegetable hole seedling cultivation substrate directly in the market without adding adhesive. The physical and chemical properties of each treated matrix block are shown in Table 2.

[0040] Table 1 Formula table of different substrates

[0041]

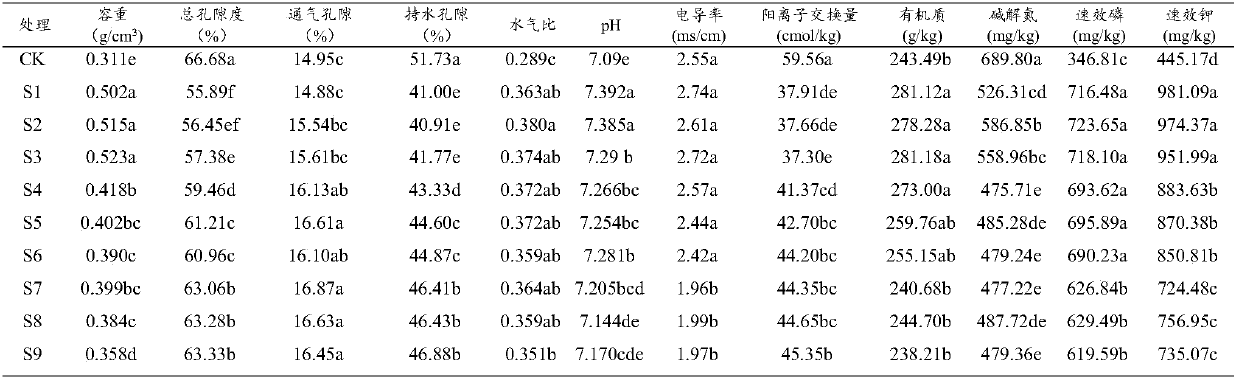

[0042] Table 2 Physicochemical properties of different matrix formulations

[0043]

[0044] Note: Different lowercase letters in the same column indicate a significant difference (P<0.05), the same below.

[0045] It can be seen from Table 2 that the bulk density of each formula and CK is within the appropriate range, among which S3 is the highest and CK is the lowest, and the difference between each formula and CK is significant; the total porosity and water-holding porosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com