High-altitude pneumatic pruning shears

A technology of pruning shears and cylinders, applied in cutting tools, cutting equipment, gardening, etc., can solve the problems of high production cost, high physical fitness requirements of operators, heavy weight, etc., and achieves adjustable pruning height, good energy-saving effect, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

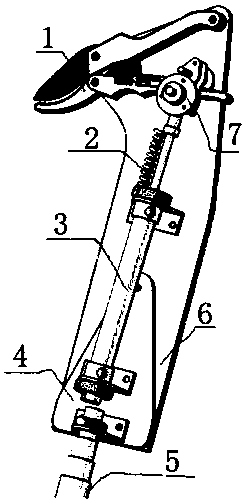

[0021] This embodiment provides a high-altitude pneumatic pruning shears, including: wheeled scissors, pull-back springs, cylinders, reinforcement plates, connectors, fixed plates, telescopic rods, and Bluetooth switch modules; one handle of the wheeled scissors is a rotating handle, Cooperate with the connecting head through grooves and wheels, the other handle is fixed on the fixed plate, the connecting head is installed on the push rod of the cylinder, the push rod is provided with a pull-back spring, one end of the cylinder is fixed on the fixed plate, The other end is fixed on the reinforcing plate, and the reinforcing plate is connected with the fixed plate, and the top of the telescopic rod is fixed on the reinforcing plate; the on-off of the solenoid valve switch is controlled by the bluetooth switch module to control the thrust of the cylinder.

Embodiment 2

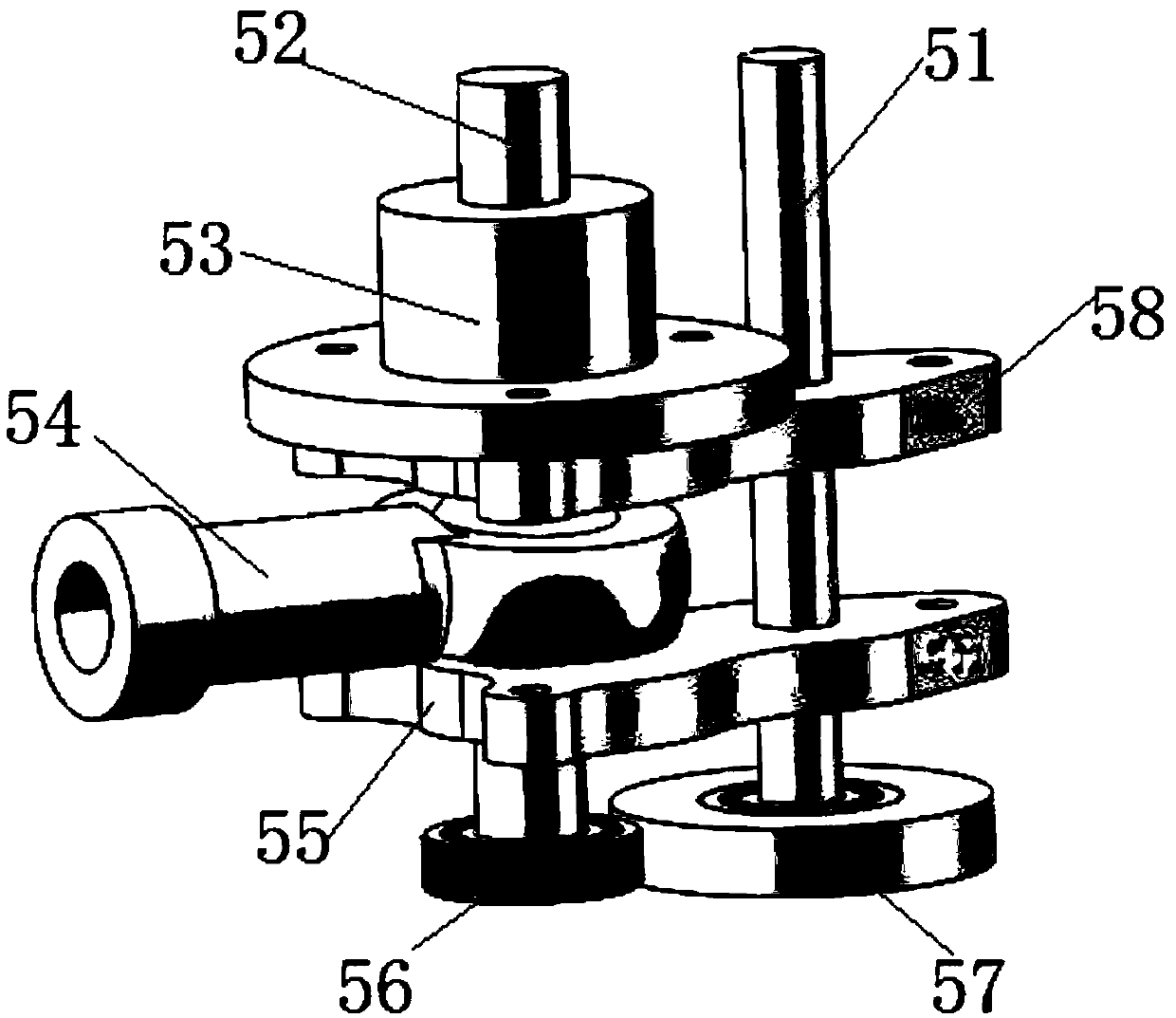

[0023] As a further limitation to Embodiment 1, the connector includes: shaft a, shaft b, rod end bearing, thin-walled bearing a, thin-walled bearing b, flange bushing, distance adjusting piece a, distance adjusting piece b , Bearing sleeve; shaft a passes through the distance adjusting piece a and the distance adjusting piece b, the thin-walled bearing a is fixed on the end of the shaft a, and the bearing sleeve is placed around the outer circumference of the thin-walled bearing a; the shaft b passes through the The flange bushing, the distance adjusting piece a, the rod end bearing, and the distance adjusting piece b, the thin-walled bearing b is fixed on the end of the shaft b.

[0024] The pruning shears use the manual adjustment of the telescopic rod to adjust the scissors to the desired height of the operator, and then manually control the Bluetooth switch module to change the on and off of the solenoid valve switch (model 3V 210-08, the air inlet and outlet ports are rev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com