Two-part adhesive comprising phenoxyethyl methacrylate and tetrahydrofurfuryl methacrylate, and structure including cured material thereof

A technology of phenoxyethyl methacrylate and tetrahydrofurfuryl methacrylate, applied in the field of reactive binary adhesives, can solve the problems of complex adhesion, inability to obtain adhesive force, expensive treatment, etc., and achieve excellent The effect of adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 5 and comparative example 1 to 13

[0095] Synthesis of α-methylstyrene-group-containing oligomers (AMSPU) >

[0096] 120.60 g of TMI and 600.00 g of JEFFAMINE (trademark) D2000 were mixed and reacted at room temperature for one day and one night without temperature adjustment. Confirmed by the results of IR spectrophotometry, the wavenumber is 2,265cm -1 The peak caused by the isocyanate disappears, and the reaction is concluded. In this way, α-methylstyrene-group-containing oligomers (AMSPU) are obtained.

[0097] Initiator >

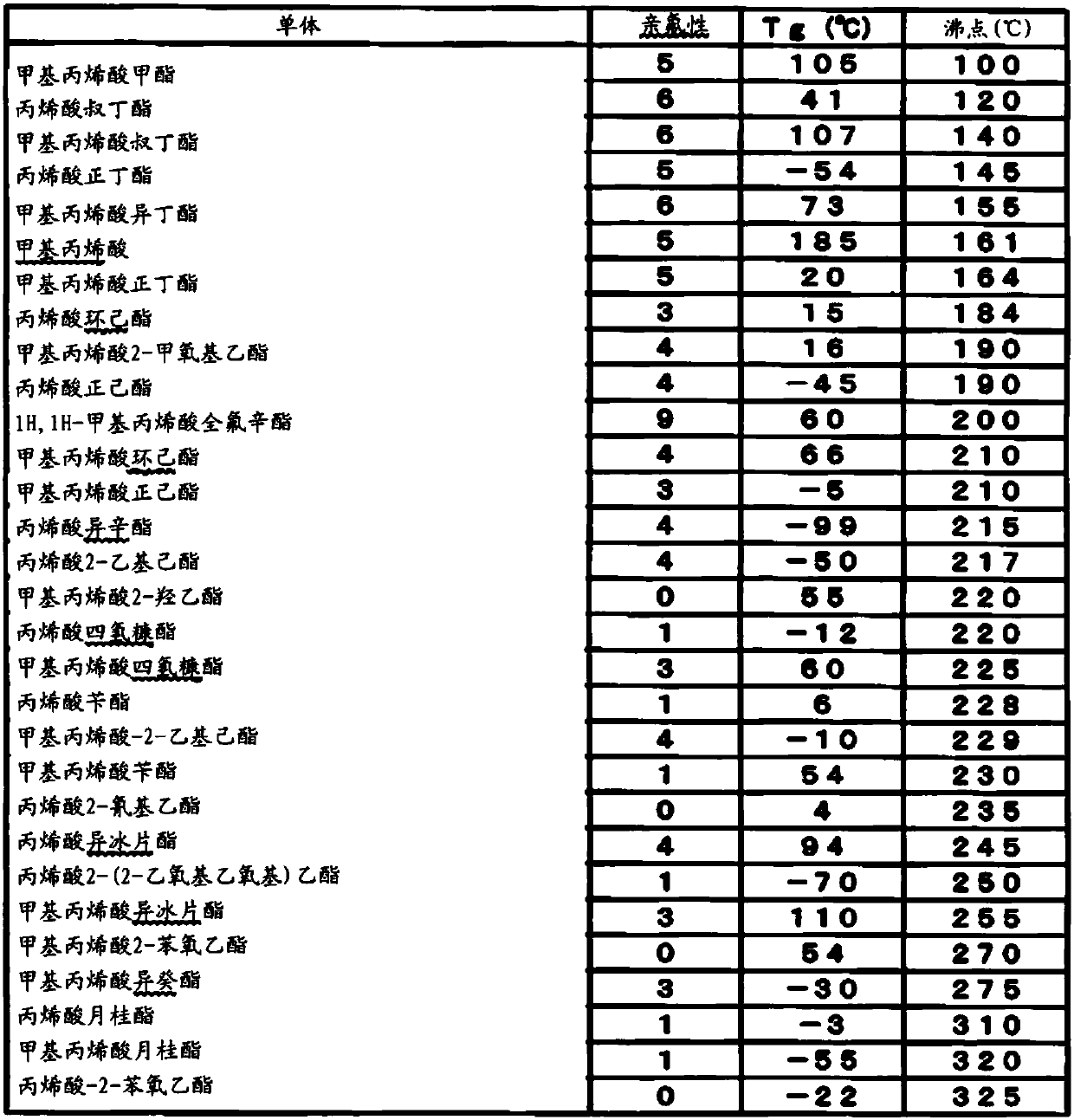

[0098] Materials used for the initiators are shown in Table 1. Triethylborane:1,6-hexa 35% CX-100 solution of methylenediamine complex (TEB / HMDA / CX-100). Weigh 33.90 g TEB / HMDA / CX-100, 62.30 g AMSPU, 3.60 g TS 720 and 0.20 g M 460 in a 200-mL glass bottle, and use "Awatori rentarō" ARE-500 (Thinky Company, Chiyoda-ku, Tokyo, Japan) (Planetary mixer manufactured by Thinky Corporation, Chiyoda-ku, Tokyo, Japan)) was stirred at 2,000 rpm for 2 minutes to obtain an initiator. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com