Systems and methods for humidity determination and uses thereof

A technology of relative humidity and sensors, which is applied in the direction of material analysis, instruments, and measuring devices using sound waves/ultrasonic waves/infrasonic waves, and can solve problems such as deterioration and sensor blackening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

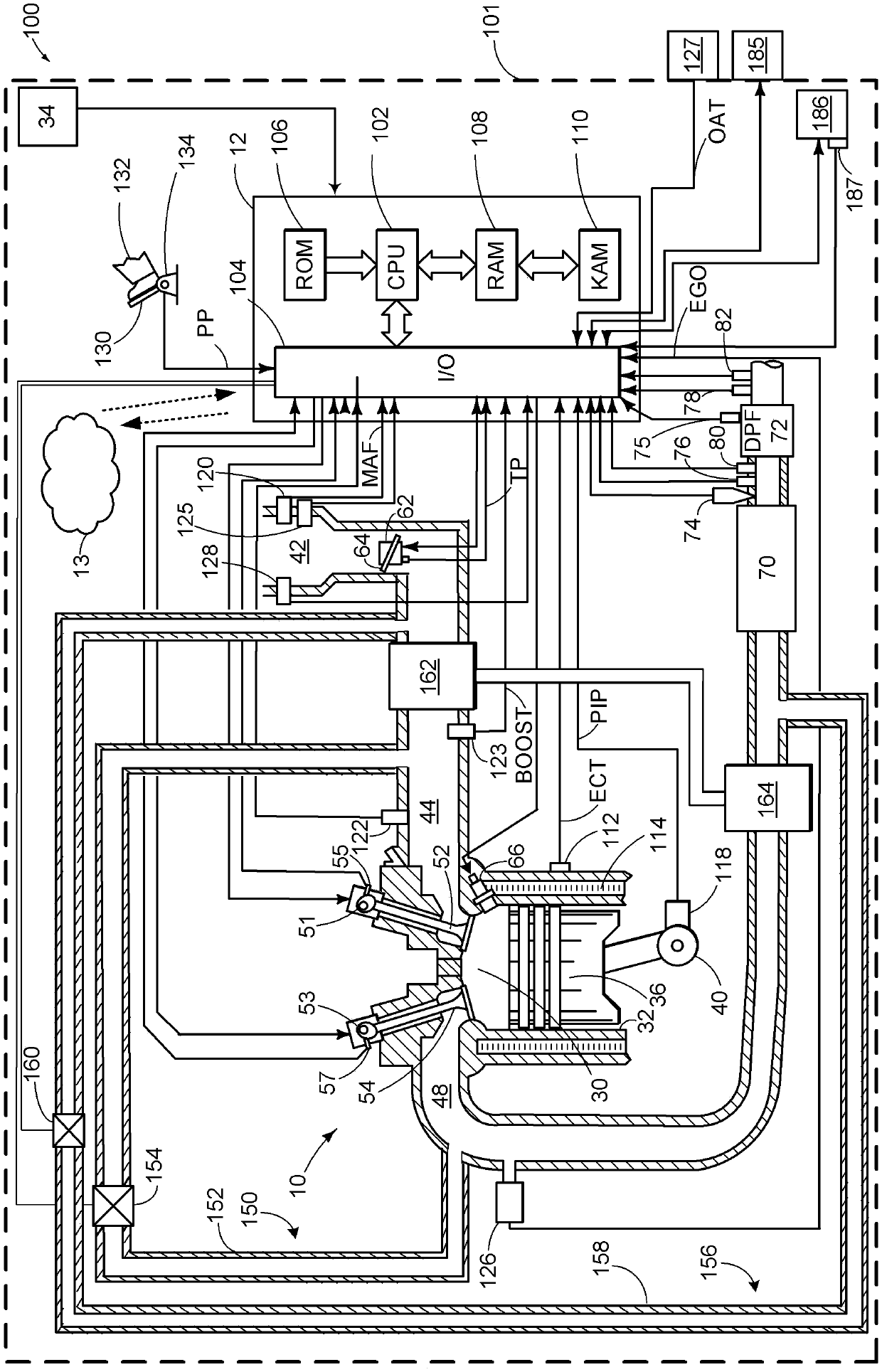

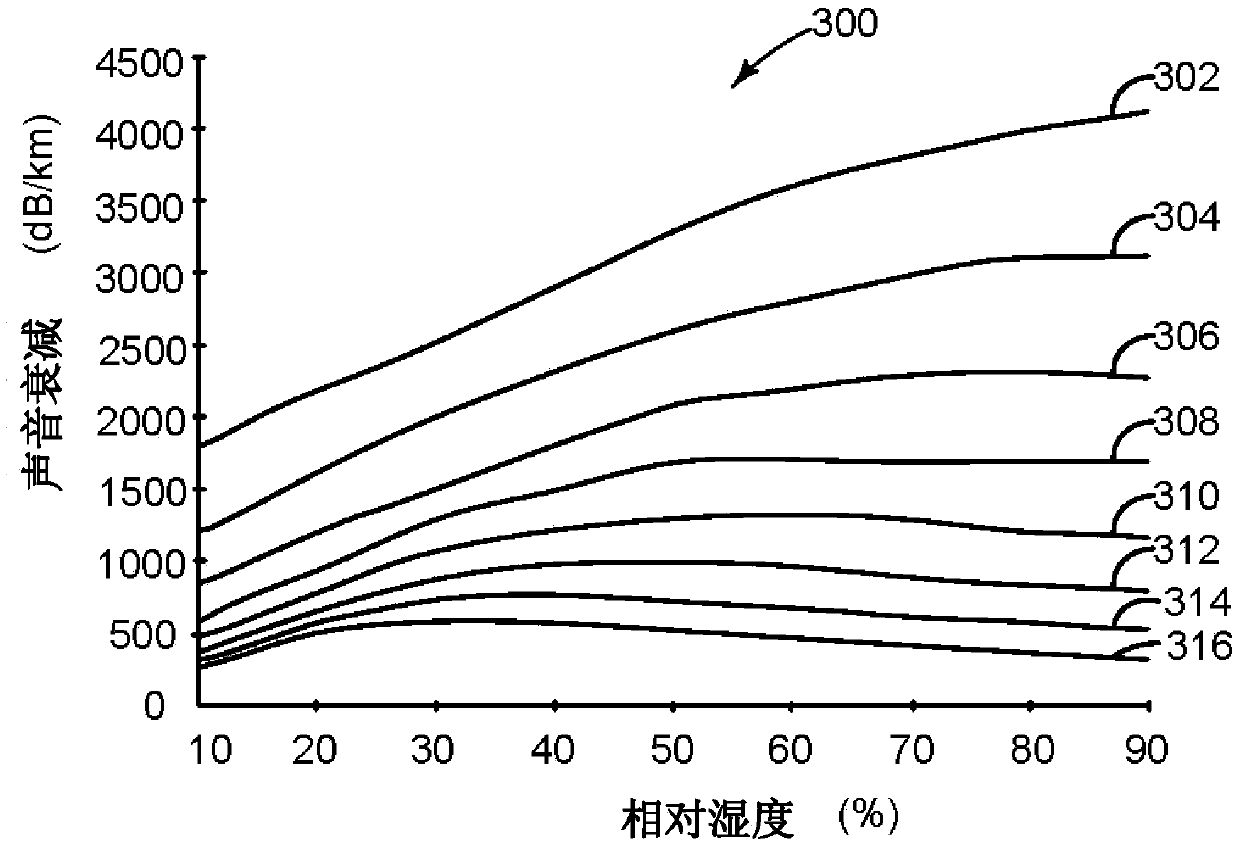

[0030] The following description relates to systems and methods for making relative humidity measurements and adjusting vehicle operating parameters in response to relative humidity determinations. Such measurements can be made by vehicle systems including internal combustion engines such as figure 1 Implementation of the vehicle system depicted in , where the vehicle may be further configured with one or more on-board cameras and one or more ultrasonic sensors. In some examples, the vehicle may be a hybrid vehicle capable of operating for an extended period of time without engine operation. Knowledge of relative humidity can improve the functionality of, for example, assisted or fully automated parking programs that can be accessed via, for example, figure 2 shown in the parking assist system. In some examples, such as Figure 3A As shown, a humidity measurement can be determined via an ultrasonic sensor based on the relationship between sound attenuation, relative humidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com