Thermoacoustic vibration suppression device for liquid helium container based on variable volume damping gas storage

A technology of thermoacoustic oscillation and suppression device, applied in pressure vessels, container filling methods, container discharge methods, etc., can solve the problems of increased evaporation loss of liquid helium, pressure and temperature fluctuations, and weakened thermoacoustic oscillation suppression effect, etc. Achieve the effect of good high pressure resistance, thermoacoustic oscillation suppression, and the best suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment and accompanying drawing, the present invention is described in detail, and present embodiment is carried out under the premise of technical solution of the present invention, has provided detailed implementation mode and specific operation process, but protection scope of the present invention is not limited to the following the described embodiment.

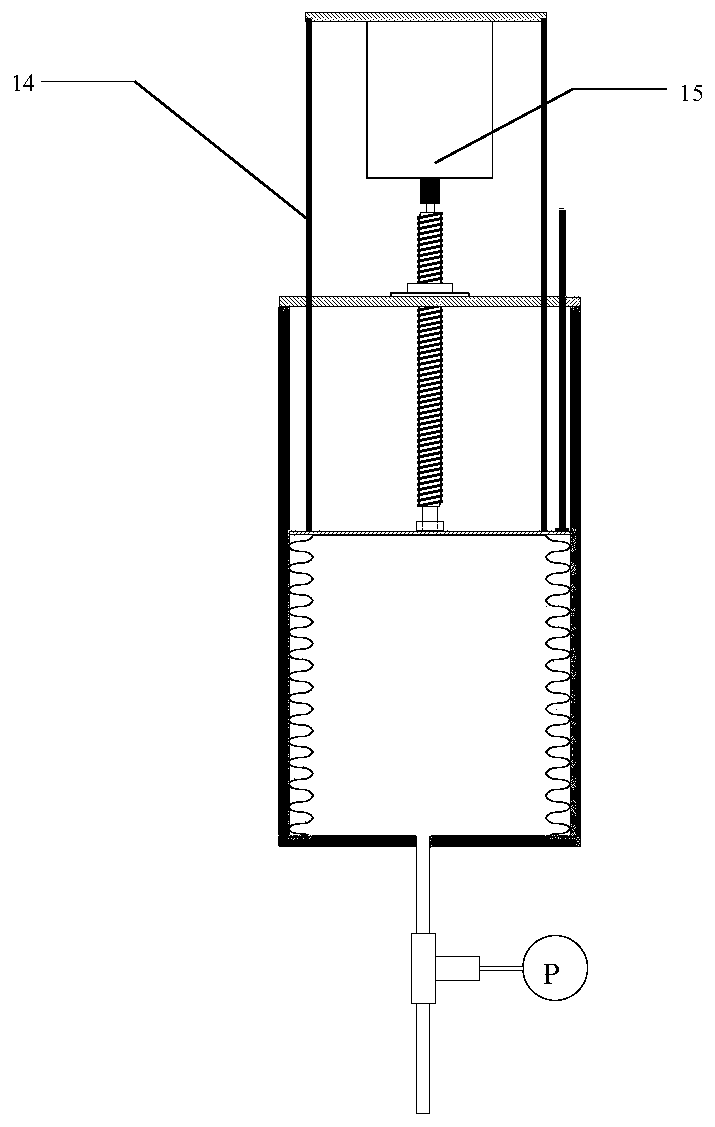

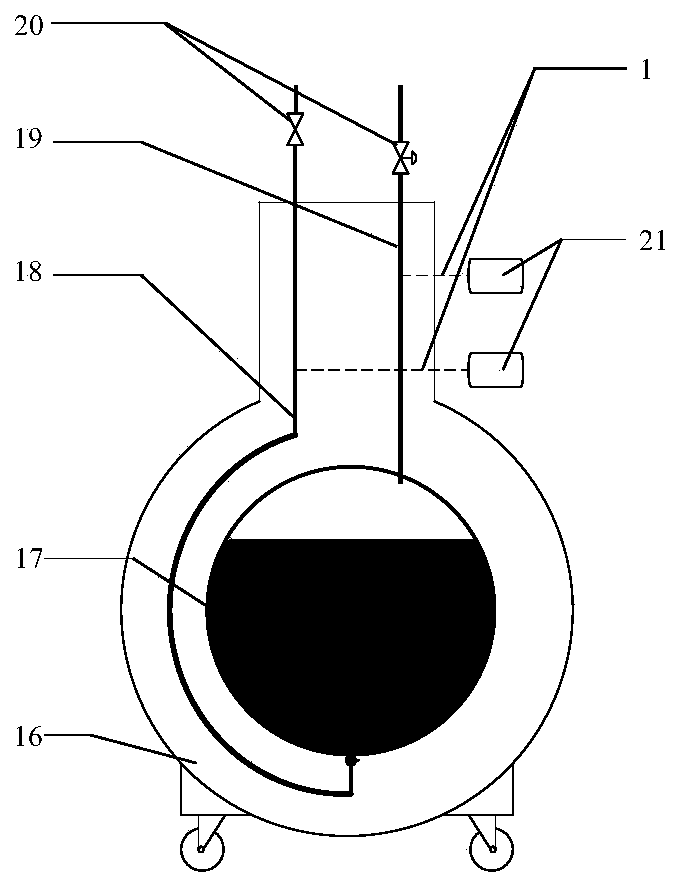

[0027] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of Embodiment 1 of a thermoacoustic oscillation suppression device for a liquid helium container based on a variable volume damping gas storage of the present invention. As can be seen from the figure, the present invention is based on a variable volume damping gas storage device for liquid helium container thermoacoustic oscillation suppression, including a capillary 1, a gas storage sleeve 2, a damping gas storage 3, a moving plate 4, a screw fixed bearing 5, and a ball screw 6. Nut pair 9, lead screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com