Buffer energy-absorbing wall structure for front of highway tunnel

A technology for road tunnels and columnar structures, applied in the field of building construction and building structures, can solve the problems of secondary damage of vehicles, prone to collapse, lack of flexibility of walls, etc., to reduce damage, reduce rebound effect, and enhance wall stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

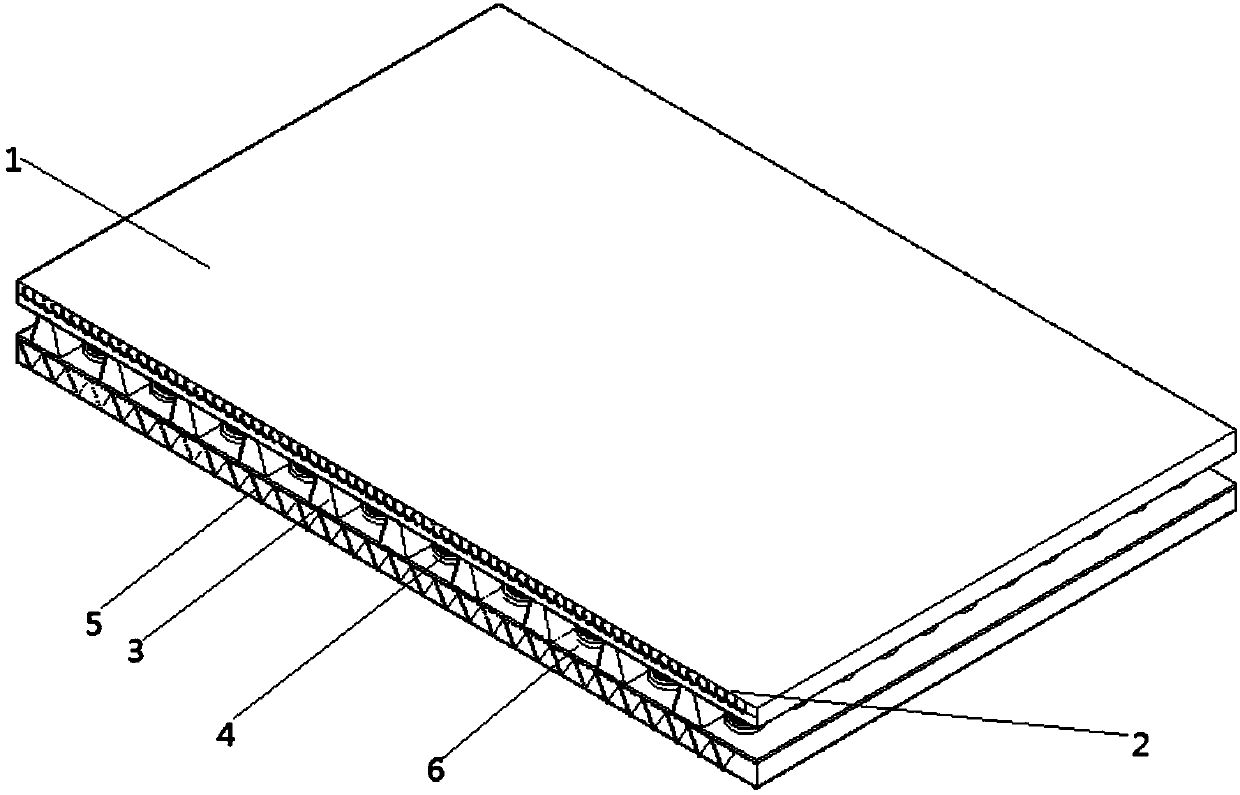

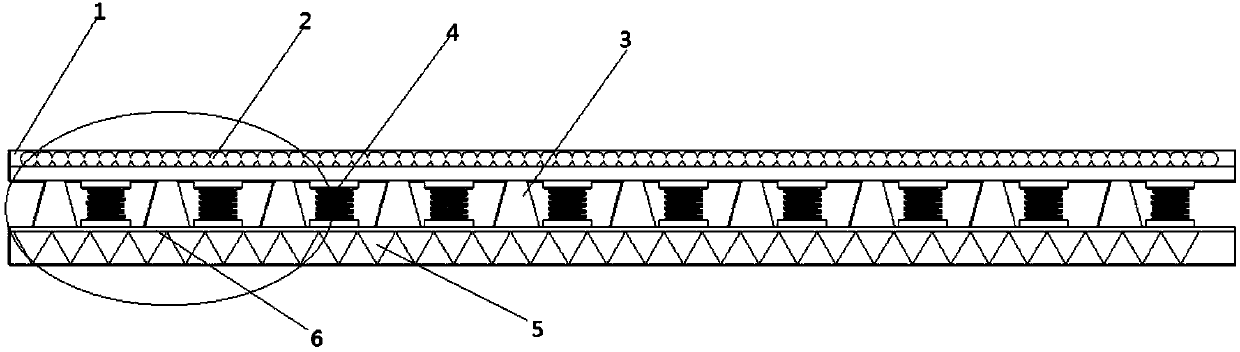

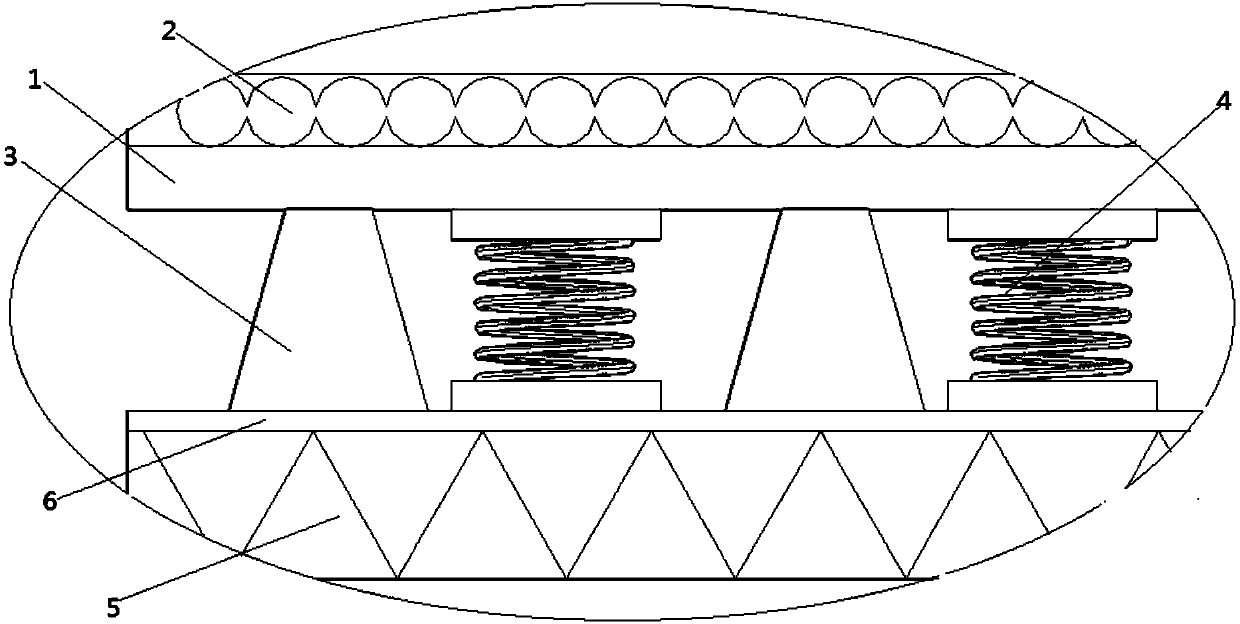

[0028] as attached figure 1 to attach Figure 5 Shown:

[0029] The present invention provides a buffer energy-absorbing wall structure in front of a highway tunnel, including a concrete layer 1, a cylindrical connecting body 2, a trapezoidal block 3, a shock absorbing group 4, a pressure dislocation body 5, a support plate 6, an upper washer 401, a spring 402 and a lower Gasket 403, the surface of the cylindrical connecting body 2 and the gaps are filled with concrete layer 1, and the cylindrical connecting body 2 is arranged horizontally on the wall surface; the bottom of the concrete layer 1 below the cylindrical connecting body 2 is fixedly arranged on the trapezoidal block 3 Top; the trapezoidal blocks 3 are arranged at intervals and a shock absorbing group 4 is arranged between every two trapezoidal blocks 3; the bottom of the shock absorbing group 4 and the trapezoidal block 3 is provided with a support plate 6; the bottom of the support plate 6 is laid There are pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com